Quinary high-entropy alloy oxide negative electrode material and preparation method and application thereof

A technology of high-entropy alloys and negative electrode materials, applied in nanotechnology for materials and surface science, electrical components, battery electrodes, etc., to achieve the effects of good cycle specific capacity, good conductivity, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A five-element high-entropy alloy oxide negative electrode material and a preparation method thereof, comprising the steps of:

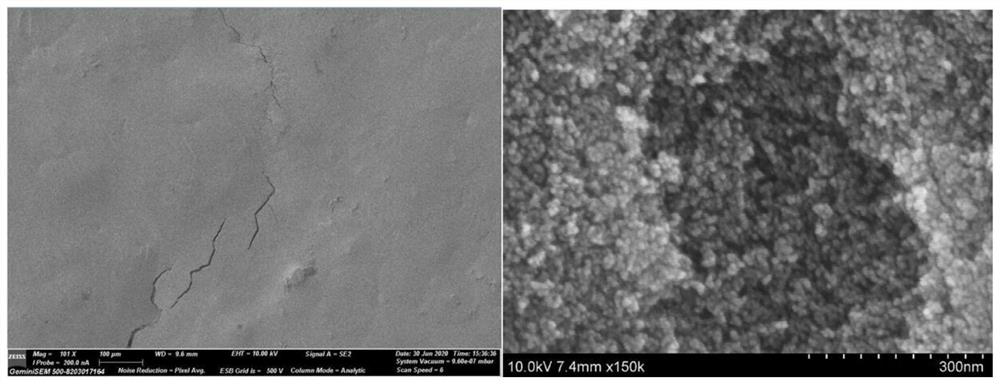

[0040] (1) Preparation of multi-element alloy strips: Analytical pure Ni, Cu, Fe, Co, Mn metal particles are selected as particles with a diameter of 1-5mm, and are smelted according to the atomic ratio of 8:8:8:8:68 - The spinning belt is prepared into a 30 μm thick alloy strip, and the spinning frequency of the stripping machine is 45 Hz, and the rotating speed is 15 m / s;

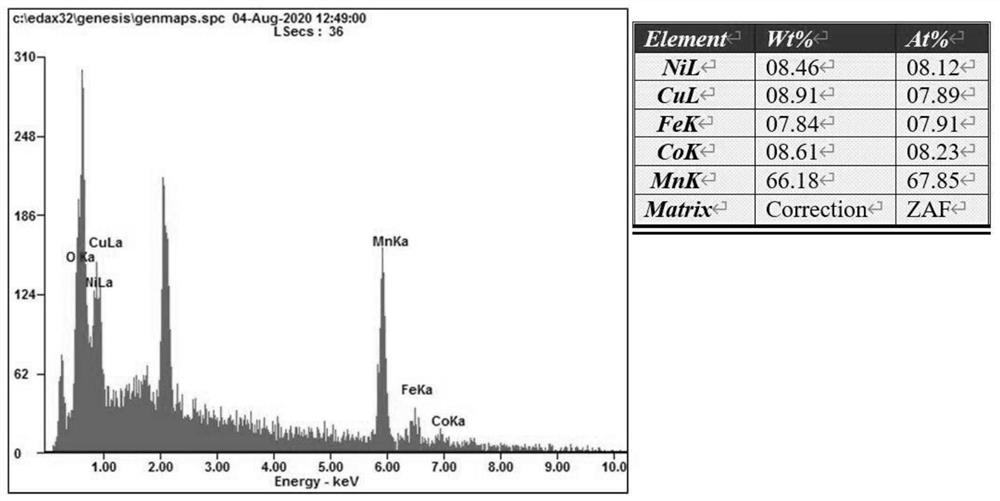

[0041] (2) Dealloying treatment: place the alloy strip prepared in step (1) in a 1mol / L ammonium sulfate solution for dealloying treatment at a temperature of 50°C and a corrosion time of 8 hours to form a homogeneous, nano Porous Multicomponent Alloys. According to EDX energy spectrum analysis, the atomic ratio of Mn after dealloying is about 15At%.

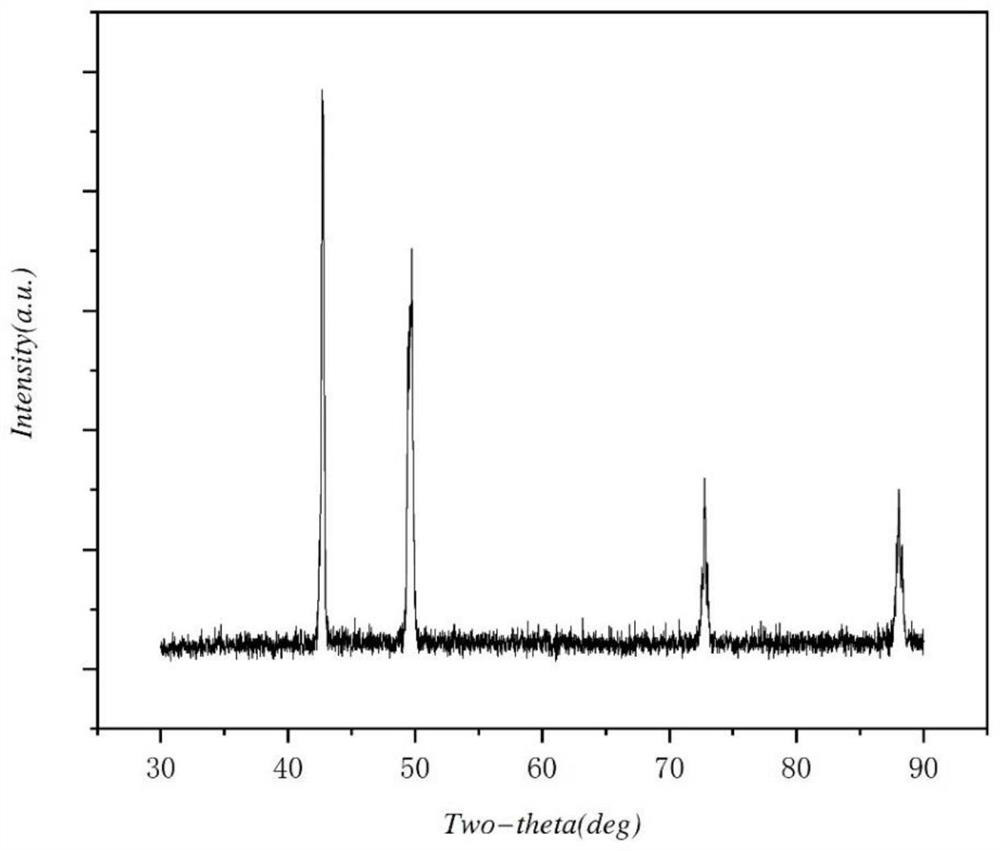

[0042] (3) Oxidation treatment: the metal after dealloying in step (2) is placed in the air atmosphere, the specific su...

Embodiment 2

[0055] A five-element high-entropy alloy oxide negative electrode material and a preparation method thereof, comprising the steps of:

[0056] (1) Preparation of multi-element alloy strips: Analytical pure Ni, Cu, Fe, Co, Mn metal particles are selected as particles with a diameter of 1-5mm, and are smelted according to the atomic ratio of 10:8:6:8:68 - The spinning strip is prepared into a 40 μm thick alloy strip, and the spinning frequency of the spinning machine is 50 Hz, and the rotating speed is 18 m / s;

[0057] (2) Dealloying treatment: place the alloy strip prepared in step (1) in a 1.5mol / L ammonium sulfate solution for dealloying treatment at a temperature of 60°C and a corrosion time of 6 hours to form a homogeneous, Nanoporous Multicomponent Alloys. According to EDX energy spectrum analysis, the atomic ratio of Mn after dealloying is about 10At%.

[0058] (3) Oxidation treatment: the metal after dealloying in step (2) is placed in the air atmosphere, the specific ...

Embodiment 3

[0065] A five-element high-entropy alloy oxide negative electrode material and a preparation method thereof, comprising the steps of:

[0066] (1) Preparation of multi-element alloy strips: Analytical pure Ni, Cu, Fe, Co, Mn metal particles are selected as particles with a diameter of 1-5mm, and are smelted according to the atomic ratio of 10:10:6:6:68 - The strip is prepared into a 50 μm thick alloy strip, and the speed frequency of the strip machine is 47 Hz, and the speed is 17 m / s;

[0067] (2) Dealloying treatment: place the alloy strip prepared in step (1) in a 2mol / L ammonium sulfate solution for dealloying treatment at a temperature of 70°C and a corrosion time of 5 hours to form a homogeneous, nano Porous Multicomponent Alloys. According to EDX energy spectrum analysis, the atomic ratio of Mn after dealloying is about 10At%.

[0068] (3) Oxidation treatment: the metal after dealloying in step (2) is placed in the air atmosphere, the specific surface area is signific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com