Preparation method of capsorubin with high light absorption ratio and capsorubin with high content

A technology of capsanthin and capsanthin, applied in chemical instruments and methods, separation/purification of carbonyl compounds, azo dyes, etc., can solve problems such as poor fluidity, poor oxidation resistance, and difficult storage, and achieve improved Oxidation resistance and stability, reduced production costs, easy and controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

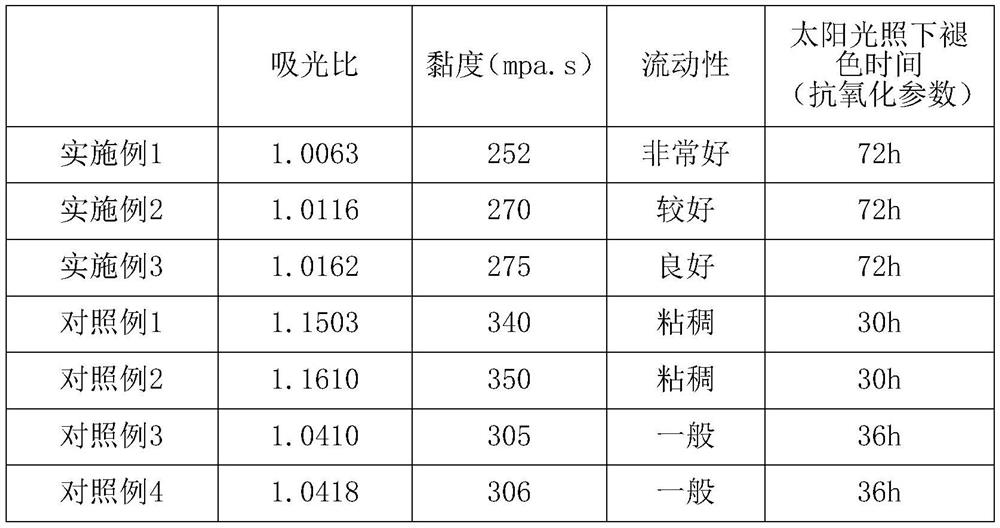

Examples

preparation example Construction

[0022] A preparation method for capsanthin with high light absorption ratio and high content capsanthin, comprising the following steps:

[0023] (1) Preparation of capsanthin with high light absorption ratio: at a certain dissolution temperature, mix capsanthin with solvent 1 in a certain proportion, stir and dissolve to obtain a solution; stir at a certain adsorption temperature, and add adsorption Activated clay for stirring and adsorption; filter the completely adsorbed liquid, collect filtrate 1 and filter residue 1, wash filter residue 1 with solvent 1 to obtain washing liquid 1 and filter residue 2, and combine washing liquid 1 and filtrate 1 to obtain filtrate 2; The filtrate 2 is evaporated and concentrated under reduced pressure to obtain capsanthin with a high light absorption ratio, and the liquid evaporated and concentrated is reused as solvent 1;

[0024] (2) Preparation of high-content capsanthin: the filter residue 2 was eluted with eluent 1 and filtered under ...

Embodiment 1

[0033] (1) Preparation of high absorbance ratio capsanthin:

[0034] Weigh capsanthin (color value and absorbance ratio are respectively 226.37 / 0.9804) 100kg, add 1000L n-hexane, mix and stir for 20 minutes, dissolve completely;

[0035] At 25°C, add 200 kg of activated clay to the n-hexane solution of capsanthin while stirring, and the stirring time is 1.5 hours to completely absorb capsanthin;

[0036] Add the completely adsorbed liquid into the plate-and-frame filter for filtration. The high-absorbance ratio component liquid enters the collection tank to obtain filtrate 1. The activated clay in the filter chamber is filter residue 1. Add 200L n-hexane to wash filter residue 1 to obtain washing liquid 1. and filter residue 2, washing liquid 1 is combined with filtrate 1 to obtain filtrate 2;

[0037] The filtrate 2 is concentrated under reduced pressure: the filtrate 2 is first concentrated by rising film evaporation at a temperature of 50°C and a vacuum of -0.04Mpa, and th...

Embodiment 2

[0043] (1) Preparation of high absorbance ratio capsanthin:

[0044] Weigh capsanthin (color value and light absorption ratio are respectively 226.37 / 0.9804) 100kg, add 1500L cyclohexane, mix and stir for 25 minutes, dissolve completely;

[0045] At 30° C., add 300 kg of activated clay to the cyclohexane solution of capsanthin while stirring. The stirring time is 1 hour to completely absorb capsanthin.

[0046] Add the completely adsorbed liquid into the plate and frame filter for filtration, and the high absorbance ratio component liquid enters the collection tank to obtain filtrate 1. The activated clay in the filter chamber is the filter residue 1, and 150L cyclohexane is added to wash the filter residue 1 to obtain the washing liquid 1 and filter residue 2, washing solution 1 is combined with filtrate 1 to obtain filtrate 2;

[0047] The filtrate 2 is concentrated under reduced pressure: first, the filtrate 2 is concentrated by rising film evaporation at a temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com