High-performance paste interface primer two-in-one coating and preparation method thereof

A two-in-one, high-performance technology, applied in the coating and other directions, can solve the problems of peeling and chalking of the paint film, and achieve the effect of strong construction performance, reduced coating process, and excellent adhesion strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

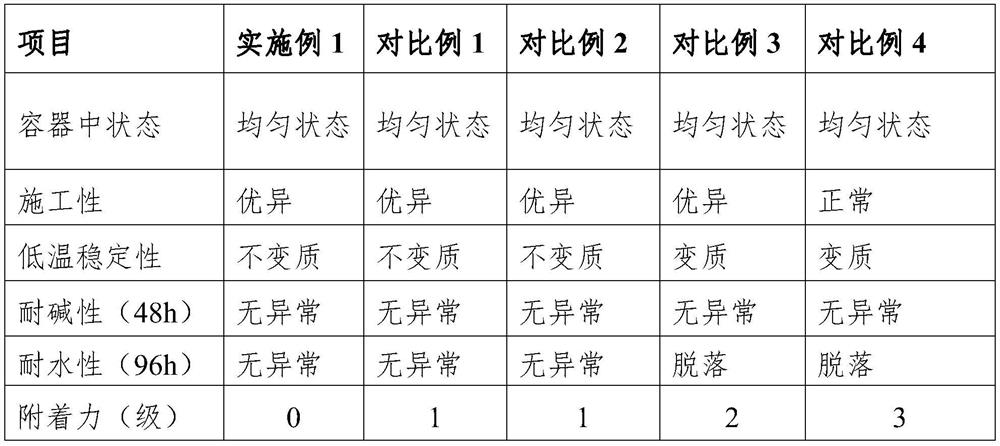

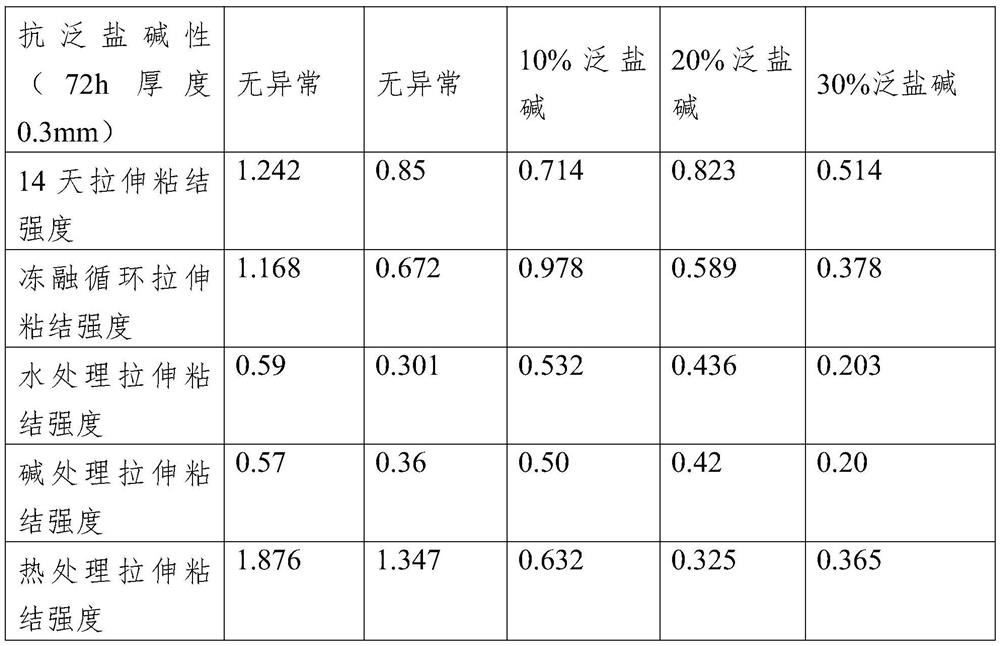

Examples

Embodiment approach 1

[0048] To decorate the wall, after scraping the putty, apply the interface agent after polishing and smoothing, and then paint the topcoat (or diatom mud construction, wallpaper paving). Or apply the interface agent after scraping the primer and then apply the topcoat and other multi-layer brushing processes. The high-performance paste interface primer two-in-one coating proposed in this embodiment improves the performance of the high-performance paste interface primer two-in-one coating through the use of hydroxyethyl cellulose, modified silicone acrylic copolymer emulsion and inorganic components. Excellent adhesion can be used as interface agent and primer, and because it has the function of putty filling at the same time. Through the combination of the following components, the adhesion will not be damaged by the components of heavy calcium, bentonite, sand and black paste, which are mainly composed of hydroxyethyl cellulose, modified silicone acrylic copolymer emulsion an...

Embodiment approach

[0050] The present embodiment includes the following components by weight:

[0051] 10-12 parts of water;

[0052] 0.1-0.3 parts of thixotropic lubricant;

[0053] 40-50 parts of modified silicone-acrylic copolymer emulsion;

[0054] 0.3-0.5 parts of bentonite;

[0055] 0.3-0.5 parts of dispersant;

[0056] 11-15 parts of heavy calcium;

[0057] 25-27 parts of sand;

[0058] 0.05-0.1 parts of black paste;

[0059] 0.3-0.5 parts of titanium dioxide;

[0060] 0.3-0.5 parts of hydroxyethyl cellulose;

[0061] 0.8 to 1.2 parts of film-forming aids;

[0062] 0.3-0.5 parts of ethylene glycol;

[0063] AMP-95 is 0.1 to 0.3 parts;

[0064] 0.3-0.5 parts of defoamer;

[0065] 0.2-0.3 parts of thickener;

[0066] and

[0067] 0.2-0.4 parts of anti-corrosion and anti-mold agent.

[0068] Wherein, the dispersant is one or a combination of sodium salt dispersants or ammonium salt dispersants.

[0069] Wherein, the defoamer is one or a combination of mineral oil defoamers or ...

Embodiment approach 2

[0094] This embodiment also provides a method for preparing a high-performance paste interface primer two-in-one coating, which includes the following steps:

[0095] S1 Add water into the dispersion tank, add 0.3-0.5 parts of hydroxyethyl cellulose and AMP-95 in sequence at a speed of 200-800r / min, and stir for 5-10 minutes;

[0096] S2 Increase the rotation speed to 1000-1500r / min, add thixotropic lubricant and bentonite in turn, stir for 2-4 minutes, then add dispersant and defoamer in turn, and stir for 2-4 minutes;

[0097] S3 Increase the rotation speed to 1500-2500r / min, then add titanium dioxide, heavy calcium, and sand in sequence, and stir for 10-15 minutes;

[0098] S4 Reduce the speed to 800-1500r / min, add 40-50 parts of emulsion, stir for 1-3 minutes, then add film-forming aids, ethylene glycol, black paste, anti-corrosion and anti-fungal agents and thickeners and stir evenly to obtain wall paint.

[0099] In this embodiment, first mix AMP-95, water and hydroxye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com