Oil-in-water type hydroquinone emulsion, and preparation method and application thereof

An oil-in-water, hydroquinone emulsion technology, applied in the field of medicine, can solve the problems of skin irritation, low transdermal absorption rate, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

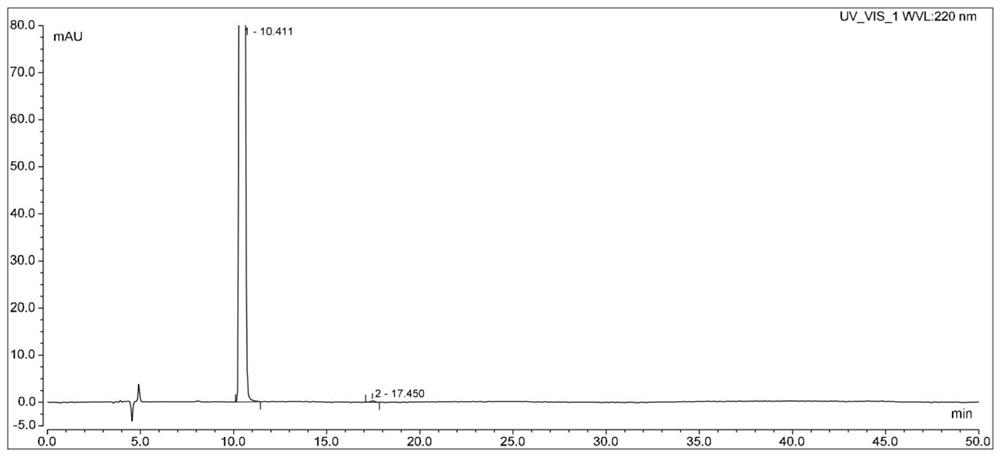

[0098] Example 1 Preparation of hydroquinone present invention

[0099] Preparation hydroquinone, comprising the steps of:

[0100] 1) The MnO 2280g, 98% sulfuric acid 430g, 2.0L of water added to the reaction flask, at at 5-10 deg.] C, was slowly added dropwise aniline 100g, stirred, gradually warming to about 25 ℃, until the reaction was complete. The reaction mixture was steam distillation at 60-90 deg.] C, the collected condensate was introduced benzoquinone another reaction flask;

[0101] 2) Under light shielding, nitrogen blanket, collected in the condensate of p-benzoquinone added iron powder 42g, at 90-100 deg.] C, the reaction was stirred for 3-4 hours to complete the reaction, filtered and the filtrate was collected concentrated to hydroquinone in 35% concentrate;

[0102] 3) Add the concentrated solution of sodium metabisulphite 550mg, activated carbon 2.2g, 330 mg of zinc powder, and heated to 95 deg.] C, filtered hot, the filtrate was collected, cooled to 5 ℃, stirr...

Embodiment 2

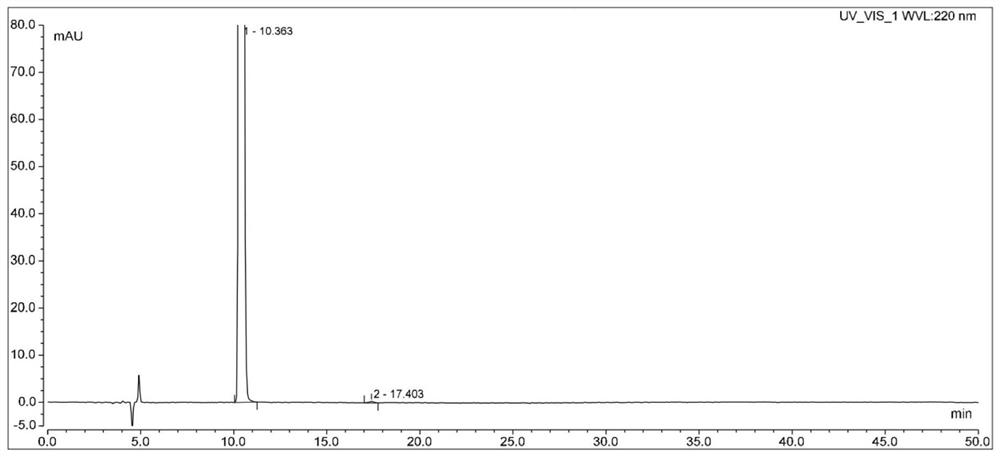

[0103] Example 2 Preparation of hydroquinone present invention

[0104] Preparation hydroquinone, comprising the steps of:

[0105] 1) The MnO 2 350g, 98% 500g sulfuric acid, the reaction flask was added 2.0L of water, at 5 ℃ -8 ℃, aniline was slowly added dropwise 100g, stirred, gradually warming to about 25 ℃, until the reaction was complete. The reaction solution was distilled under steam conditions of 60-90 ℃, the collected reaction flask was introduced p-benzoquinone another condensate;

[0106] 2) Under light shielding, nitrogen blanket, collected in the condensate of p-benzoquinone added iron powder 60g, at 90-100 deg.] C, the reaction was stirred for 2-3 hours, until the reaction was complete, filtered, and the filtrate was concentrated under reduced pressure to collect to concentrate the hydroquinone content of 25%;

[0107] 3) Add the concentrated solution 750 mg of sodium metabisulfite, activated carbon 3.1g, iron 500mg, heated to 90 ℃, filtered, and the filtrate was c...

Embodiment 3

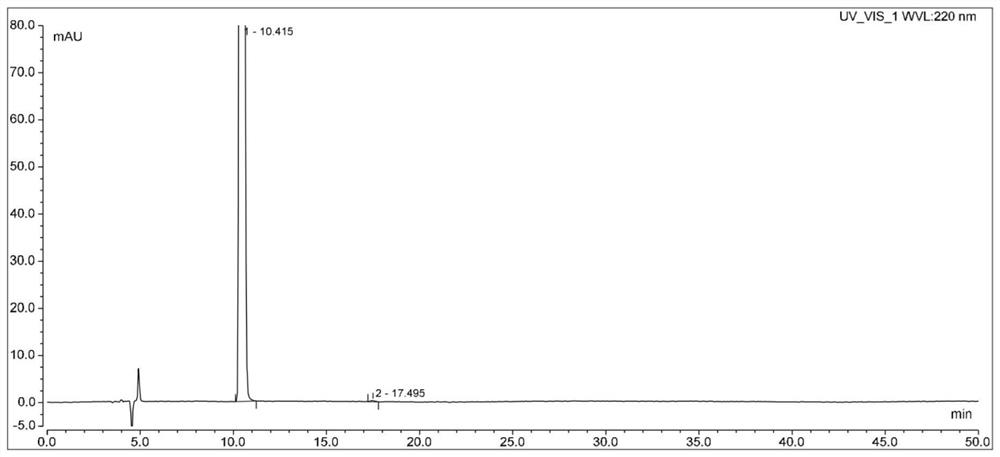

[0108] Example 3 Preparation of hydroquinone present invention

[0109] Preparation hydroquinone, comprising the steps of:

[0110] 1) The MnO 2 250g, 98% 370g sulfuric acid, the reaction flask was added 2.5L of water, at 6-10 deg.] C, was slowly added dropwise aniline 100g, stirred, gradually warming to about 25 ℃, until the reaction was complete. The reaction mixture was steam distillation at 70-95 deg.] C, the collected condensate was introduced benzoquinone another reaction flask;

[0111] 2) Under light shielding, nitrogen blanket, 31g of iron powder was added in the collected condensate of p-benzoquinone and stirred reaction at 90-100 deg.] C for 2-3 hours, until the reaction was complete, filtered, and the filtrate was concentrated under reduced pressure to collect concentrate hydroquinone content of 30%;

[0112] 3) Add the concentrated solution of sodium metabisulphite 550mg, 2.20 g of activated carbon, zinc 350mg, heated to 90 ℃, filtered, and the filtrate was cooled to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com