System and method for preparing phosphate adsorbent by taking residual sludge and biological shell wastes as raw materials

A phosphate adsorbent and excess sludge technology, which is applied in chemical instruments and methods, water pollutants, adsorbed water/sewage treatment, etc., can solve the problems of inability to prepare high-performance phosphate adsorbents, and shorten the time and operation. procedures, avoid inconsistency of operation, and improve the effect of preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

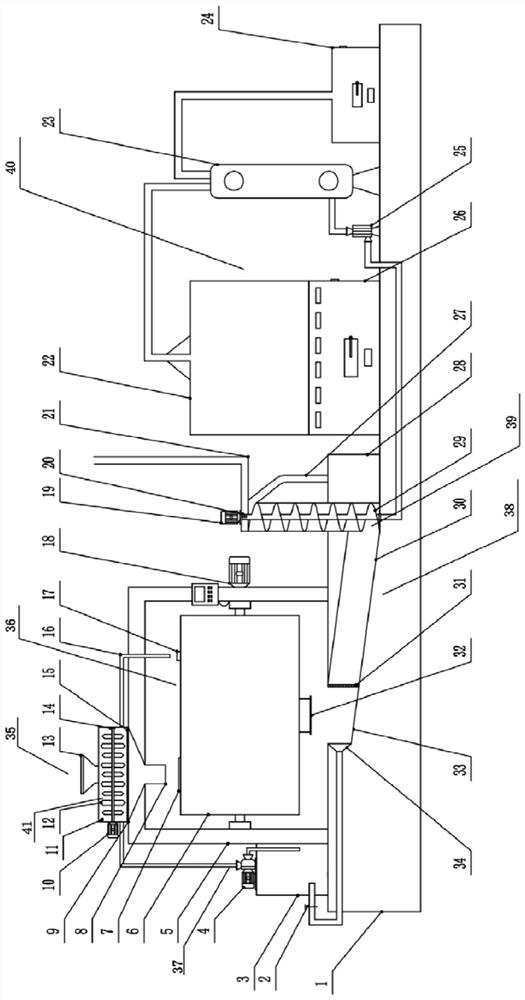

[0056] This embodiment provides a phosphate adsorbent preparation system using excess sludge and biological shell waste as raw materials, such as figure 1 As shown, it includes a crushing device 35 for crushing and drying excess sludge and biological shell waste, a ball milling device 36, a water supply device 37, a collecting and conveying device 38, a drying device 39, a storage tank 28, a carbonization device 40, and a gas purification device 23 and backup combustion device 24. The pulverizing device 35, the ball milling device 36, the collection and conveying device 38, the drying device 39, the storage tank 28 and the carbonization device 40 are set up sequentially according to the material processing sequence of crushing, ball milling, transportation, drying, storage and carbonization.

[0057] The pulverizing device 35 comprises a pulverizing chamber 41 and a discharge chamber 9 arranged from top to bottom; The blade 12 and the first driving part 10 for driving the rot...

Embodiment 2

[0070] This embodiment provides a method for preparing a phosphate adsorbent, using the phosphate adsorbent preparation system in Example 1;

[0071] The biological shell waste is oyster shells, and the dry weight ratio of oyster shells to excess sludge is 1:1; the ball milling time is 3.5 hours; the pyrolysis temperature is 800°C, and the pyrolysis time is 2 hours.

[0072] The high-efficiency phosphorus removal biochar prepared in this example is used as an adsorbent to treat phosphorus-containing wastewater with a concentration of 40 mg / L, and the adsorbent is added to the wastewater according to the ratio of wastewater volume (L) to adsorbent mass (g) ratio of 2:1 , adjust the pH to 7, and adsorb at a constant temperature for 24 hours under the condition of 25±0.5°C.

[0073] Through the above operation steps, the phosphorus concentration in the solution was reduced to 5.27 mg / L, that is, the removal rate reached 86.8%, and the adsorption capacity of the modified biochar w...

Embodiment 3

[0075] This embodiment provides a method for preparing a phosphate adsorbent, using the phosphate adsorbent preparation system in Example 1;

[0076] The biological shell waste is egg shells, and the dry weight ratio of egg shells to excess sludge is 1:1; the ball milling time is 3.5 hours; the pyrolysis temperature is 800°C, and the pyrolysis time is 2 hours.

[0077] The high-efficiency phosphorus removal biochar prepared in this example is used as an adsorbent to treat phosphorus-containing wastewater with a concentration of 40 mg / L, and the adsorbent is added to the wastewater according to the ratio of wastewater volume (L) to adsorbent mass (g) ratio of 2:1 , adjust the pH to 7, and adsorb at a constant temperature for 24 hours under the condition of 25±0.5°C.

[0078] Through the above operation steps, the phosphorus concentration in the solution is reduced to 3.76mg / L, that is, the removal rate reaches 90.6%, and the adsorption capacity of the modified biochar is 72.48m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com