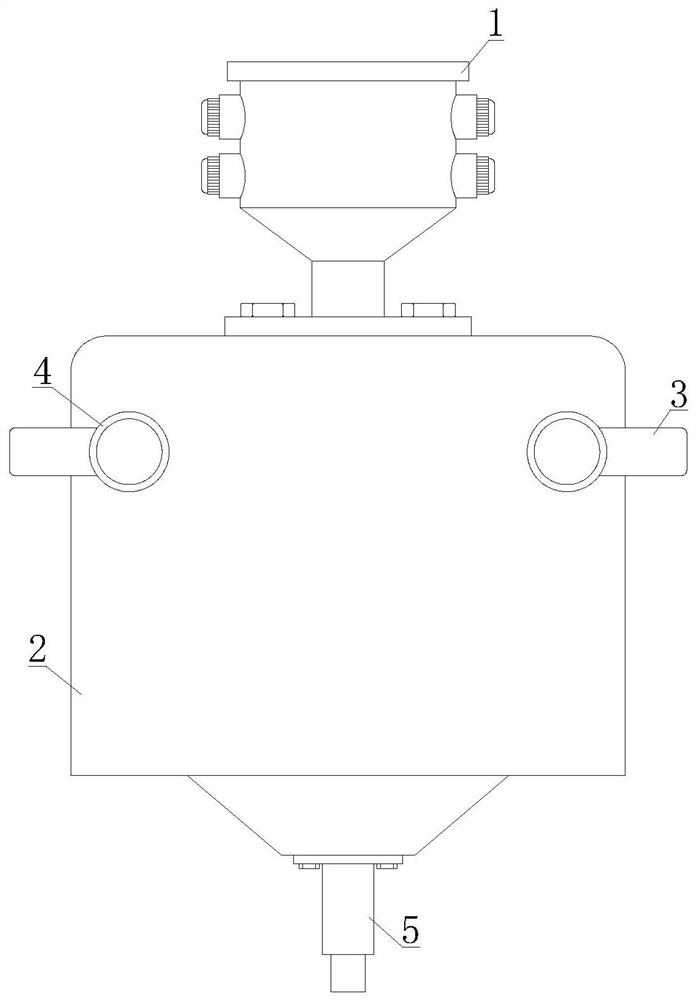

Multi-channel stone removing device for rice processing and implementation method thereof

A rice processing and paddy technology, applied in the field of paddy processing, can solve the problems of inability to ensure that impurities are removed cleanly, impurity removal, affecting safe production, etc., achieving fast and convenient stone removal operations, reducing consumption time, and reducing the content of impurities. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

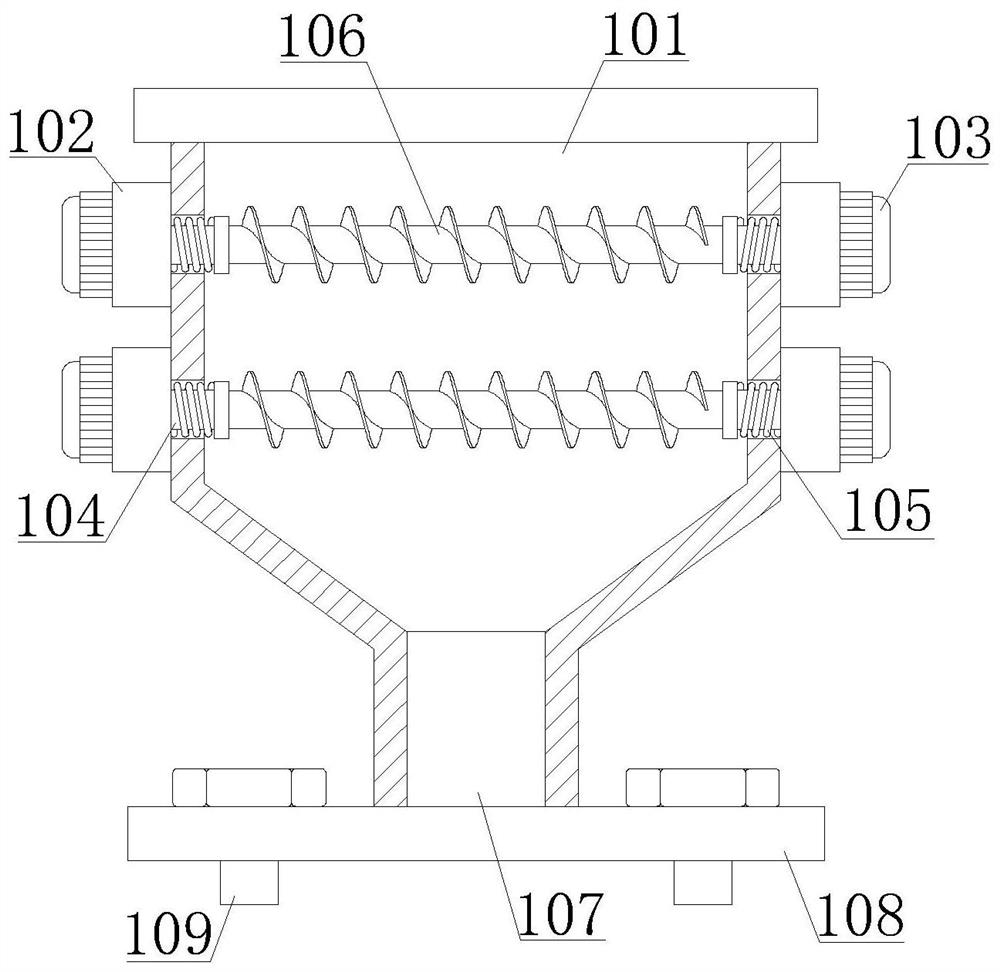

[0035] In order to better demonstrate the implementation process of the multi-channel stone removal device for rice processing rice, this embodiment now proposes an implementation method of the multi-channel stone removal device for rice processing paddy, including the following steps:

[0036] Step 1: Slowly pour rice into the grinding feeding mechanism 1 from the opening at the top of the grinding feeding mechanism 1, start the grinding motor 103, drive the drive shaft 104 by the grinding motor 103, rub the grinding roller 106, and make the grinding roller The paddy between 106 is fully ground;

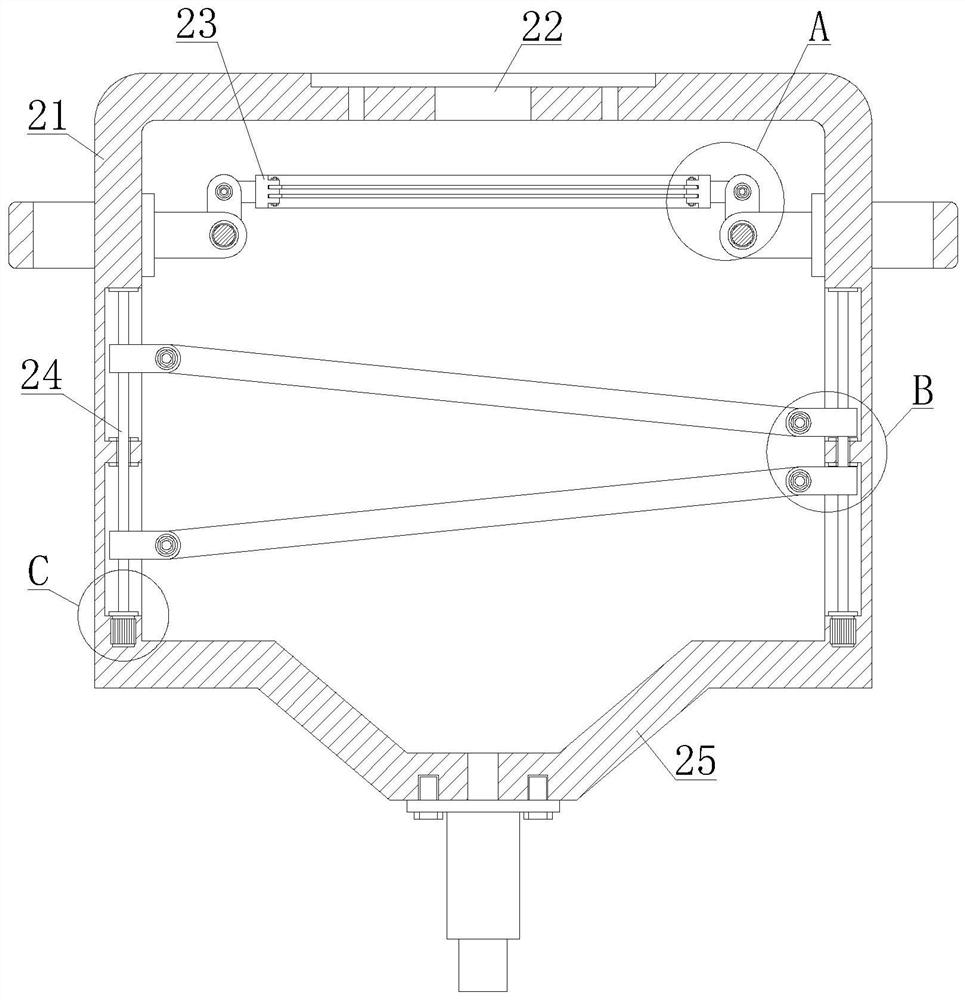

[0037] Step 2: The fully ground rice enters the stone-removing shell 2 from the feeding pipe 107 and the feeding port 22, and first falls on the stone-removing sieve plate 239 in the stone-removing screening mechanism 23;

[0038] Step 3: drive the movable shaft 232 to rotate by the external movable motor 4, and make the swing arm 233 swing, and the swing arm 233 drives the stone-re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com