Preparation method of fullerene-modified fluorene copolyester polymer material

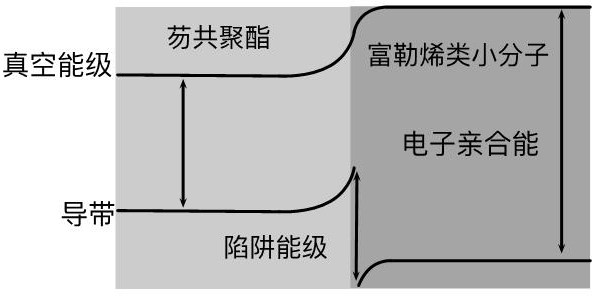

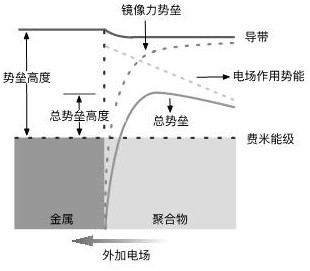

A technology of polymer materials and fluorene copolyesters, which is applied in the field of preparation of fluorene copolyester polymer materials, can solve the problems of inability to adapt to the working voltage environment, low breakdown field strength of fluorene copolyesters, and decreased energy storage density. problem, to achieve the effect of suppressing carrier migration, increasing breakdown field strength, and reducing conductance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings.

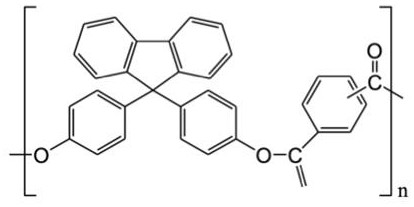

[0022] A method for preparing a fullerene-modified fluorene copolyester polymer material comprises dissolving fullerene-based small molecules and fluorene copolyester in an N-methylpyrrolidone solution respectively. After the fluorene copolyester solution was continuously stirred for 2 hours by magnetic stirring, the fullerene-based small molecule solution was added. Then, the mixed solution is ultrasonically stirred for 1 hour, and the ultrasonic power is 150W to obtain a composite suspension in which the fullerene-based small molecules are uniformly dispersed in the fluorene copolyester. A layer of composite wet film is prepared on the glass substrate by means of drop coating. The composite wet film was placed in a forced air oven, dried at 80ºC for 12 hours to remove the solvent, then dried at 125ºC and 150ºC for 1 hour, and finally at 200ºC for 12 hours. Transfer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| discharge efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com