Preparation method of steel-based corrosion-resistant super-hydrophobic coating

A super-hydrophobic coating and corrosion-resistant technology, which is applied in coatings, anti-corrosion coatings, and devices for coating liquid on the surface, etc., can solve the problems of not being able to provide corrosion protection to the substrate, poor wear resistance and corrosion resistance, and achieve excellent Super-hydrophobic properties, excellent acid and alkali corrosion resistance, and easy-to-achieve preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

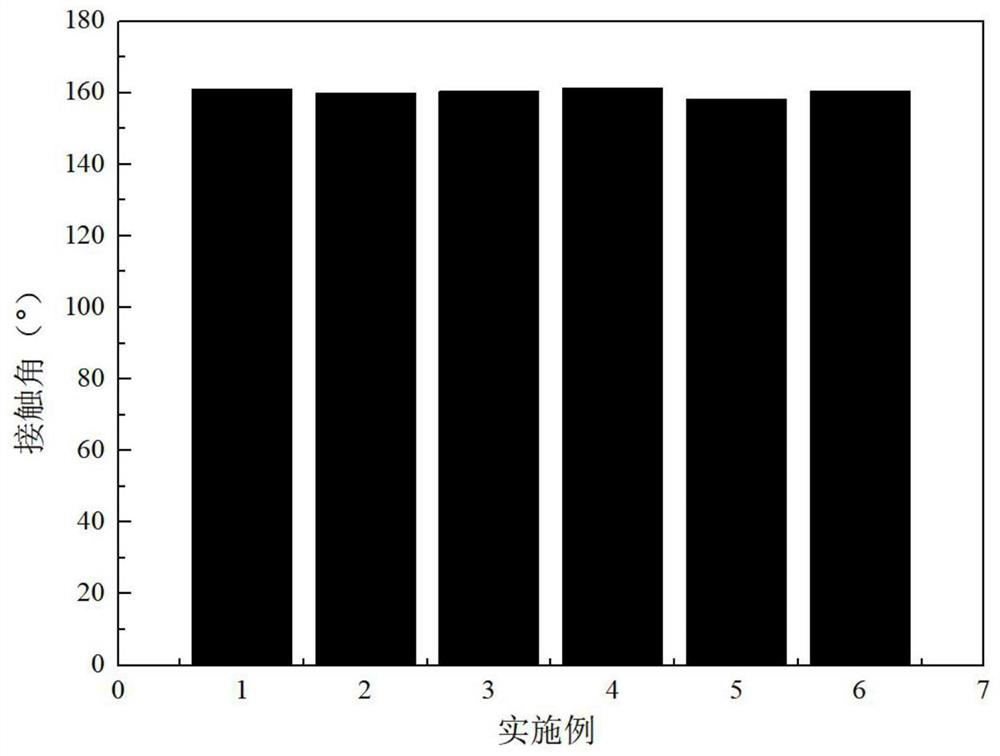

Examples

Embodiment 1

[0039] A method for preparing a steel-based corrosion-resistant superhydrophobic coating, said preparation method mainly comprising the following steps:

[0040] 1. Pretreatment of carbon nanotubes (CNTs):

[0041] Put 10g of CNTs powder in a stainless steel ball mill tank, and perform ball milling at a speed of 300r / min in an Ar protective atmosphere. Take out the ball-milled CNTs and place them in a beaker, and then add 50mL of ball-milled CNTs with a volume fraction of 60 % nitric acid, 50mL sulfuric acid mixed solution with a volume fraction of 70%, heated and stirred in an oil bath at 50°C for 5h, poured out the mixed solution, centrifuged, washed repeatedly with distilled water, removed the supernatant, and obtained acid-treated CNTs black liquid, Acidified black CNTs powder was obtained after freeze-drying at -20~-5°C for 15 hours.

[0042] 2. Preparation of superhydrophobic coating:

[0043] (1) Mix 45.2g tetraethyl silicate with 10.0g absolute ethanol, stir to form ...

Embodiment 2

[0050] A method for preparing a steel-based corrosion-resistant superhydrophobic coating, said preparation method mainly comprising the following steps:

[0051] Pretreatment of carbon nanotubes (CNTs):

[0052] Put 15g of CNTs powder in a stainless steel ball mill tank, and perform ball milling at a speed of 400r / min in an Ar protective atmosphere. Take out the ball-milled CNTs and place them in a beaker, add 60mL of nitric acid and 60mL of sulfuric acid mixed solution, and put them in oil at 60°C. Heated and stirred in the bath for 5 hours, poured out the mixture, centrifuged, washed repeatedly with distilled water, and removed the supernatant to obtain acid-treated CNTs black liquid, and freeze-dried for 15 hours to obtain acidified CNTs black powder.

[0053] Preparation of superhydrophobic coating:

[0054] (1) Mix 73.8g butyl titanate with 10.0g absolute ethanol, stir to form solution A;

[0055] (2) Mix 40mL of deionized water with 40mL of absolute ethanol, and add dr...

Embodiment 3

[0061] A method for preparing a steel-based corrosion-resistant superhydrophobic coating, said preparation method mainly comprising the following steps:

[0062] Pretreatment of carbon nanotubes (CNTs):

[0063] Put 15g of CNTs powder in a stainless steel ball mill tank, and conduct ball milling at a speed of 350r / min in an Ar protective atmosphere. Take out the ball-milled CNTs and place them in a beaker, add 60mL of nitric acid and 60mL of sulfuric acid mixed solution, and put them in oil at 65°C. After heating and stirring in the bath for 6 hours, the mixture was poured out, centrifuged, and washed repeatedly with distilled water, and the supernatant was removed to obtain acid-treated CNTs black liquid, which was then freeze-dried for 20 hours to obtain acidified CNTs black powder.

[0064] Preparation of superhydrophobic coating:

[0065] (1) Mix 61.7g of tetraisopropyl titanate with 10.0g of absolute ethanol, and stir to form solution A;

[0066] (2) Mix 40mL deionized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Static contact angle | aaaaa | aaaaa |

| Static contact angle | aaaaa | aaaaa |

| Static contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com