Method for separating hemicellulose from wood and bamboo raw materials through low-solid-content prehydrolysis

A technology of hemicellulose and prehydrolysis, which is applied in fiber raw materials, fiber raw material treatment, raw material pretreatment, etc., can solve the problems of low hemicellulose removal rate, poor prehydrolysis selectivity, long prehydrolysis time, etc. The effects of short hydrolysis time, improved reaction performance, and low prehydrolysis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

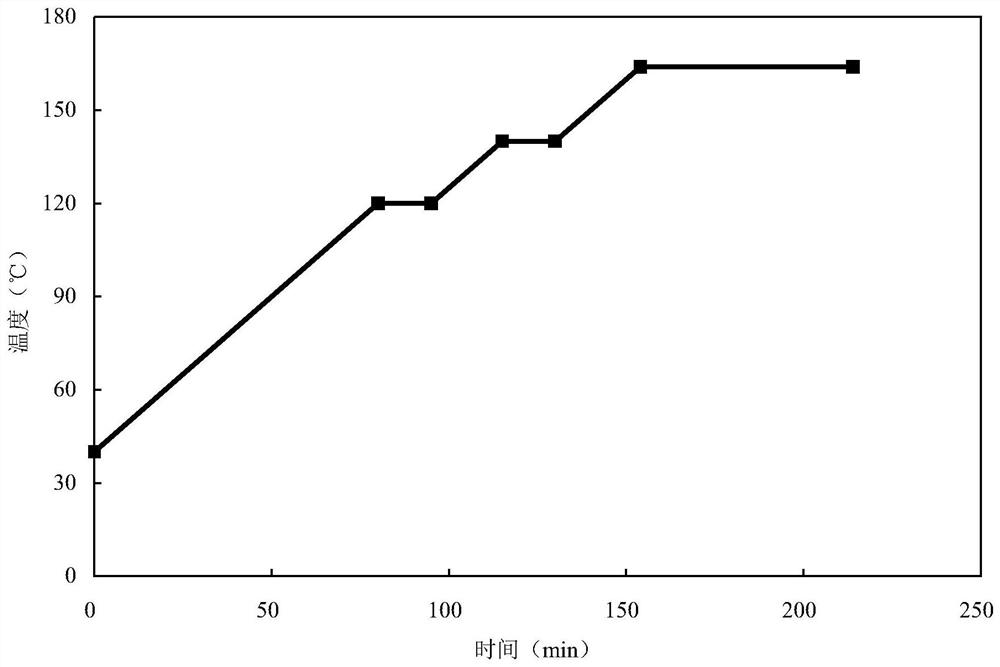

[0038] Embodiment 1 pretreatment separates bamboo raw material hemicellulose

[0039] Include the following steps:

[0040] (1) Take 2-year-old punnet bamboo raw materials, and use a Pallmann chipper to chip the bamboo material (the moisture content of the bamboo chips is 61.31%) to obtain bamboo chips with a length of 20-30 mm. After chipping, screen with a double-layer cylindrical bamboo sieve to remove broken bamboo nodes, bamboo chips and uncut bamboo strips. After screening, the bamboo chips are washed with a drum washing machine to remove impurities such as stones, silt and metal mixed in the bamboo chips. After washing, the bamboo slices are dehydrated with an inclined spiral dehydrator to remove the free water brought by the bamboo slices. The dehydrated bamboo chips are sent to the silo by the belt conveyor for use in the pre-hydrolysis section.

[0041] (2) The bamboo slices in the silo are sent to the liquid potter through the belt conveyor, and then loaded into ...

Embodiment 2

[0055] Embodiment 2 pretreatment separates pine raw material hemicellulose

[0056] Include the following steps:

[0057] (1) Take imported radiata pine wood chips and wash the wood chips with a drum washing machine to remove impurities such as stones, silt and metal mixed in the wood chips. After washing, the wood chips are dehydrated with an inclined spiral dehydrator to remove the free water brought by the wood chips. The dehydrated wood chips are sent to the silo by the belt conveyor for use in the pre-hydrolysis section.

[0058] (2) The wood chips in the silo are sent to the liquid potting device through the belt conveyor, and then loaded into the cooking vertical pot through the liquid potting device.

[0059] (3) After the cooking vertical pot is filled with wood chips, close the self-pressing automatic pot cover tightly, and start to pass in clean water. The amount of clean water is 0.15 tons / ton of dry wood chips; the liquid ratio is 1:3.6. After adding the clear...

Embodiment 3

[0072] Embodiment 3 pretreatment separates blue eucalyptus wood raw material hemicellulose

[0073] Include the following steps:

[0074] (1) Take imported blue eucalyptus wood chips and wash the wood chips with a drum washing machine to remove impurities such as stones, silt and metal mixed in the wood chips. After washing, the wood chips are dehydrated with an inclined spiral dehydrator to remove the free water brought by the wood chips. The dehydrated wood chips are sent to the silo by the belt conveyor for use in the pre-hydrolysis section.

[0075] (2) The wood chips in the silo are sent to the liquid potting device through the belt conveyor, and then loaded into the cooking vertical pot through the liquid potting device.

[0076] (3) After the cooking vertical pot is filled with wood chips, close the self-pressing automatic pot cover tightly, and start to pass in clean water. The amount of clean water is 0.16 tons / ton dry wood chips; the liquid ratio is 1:4.0. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com