Ferro-molybdenum sample and preparation method thereof, and method for determining content of components in ferro-molybdenum alloy

A ferromolybdenum alloy and ferromolybdenum technology, which is applied in the field of composition analysis, can solve the problems of inaccurate analysis of ferromolybdenum composition, achieve the effect of improving cumbersome detection steps, long and accurate detection cycle, and avoiding waste and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

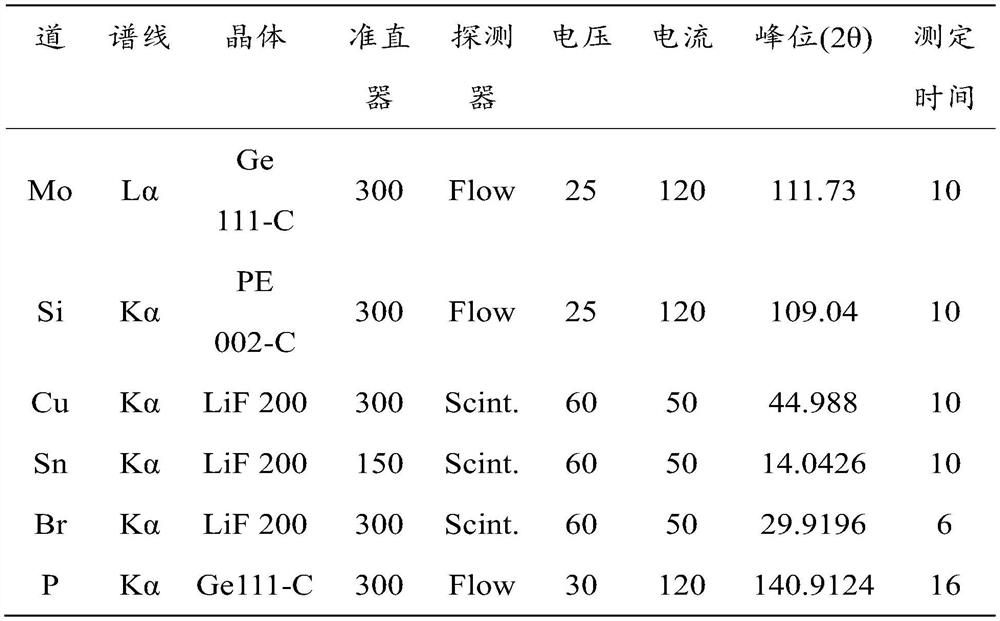

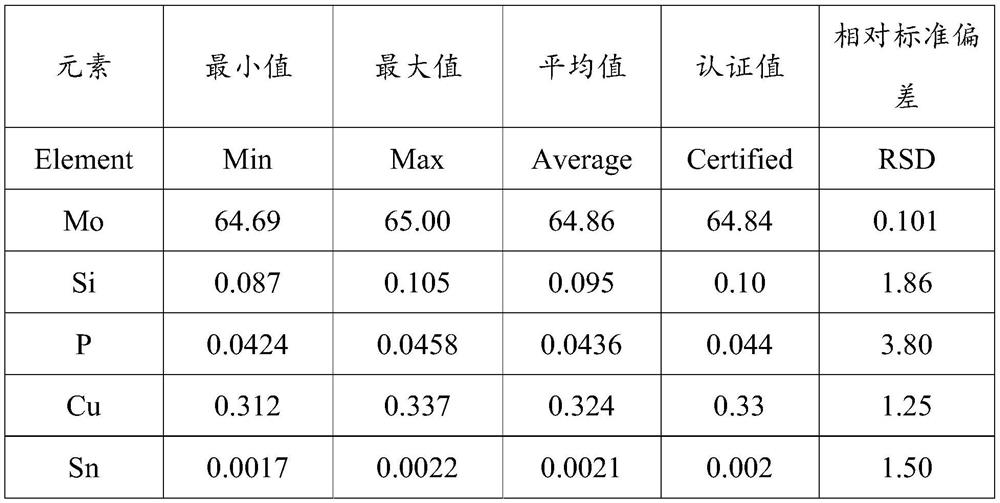

[0036] A method for preparing a ferromolybdenum sample, the ferromolybdenum sample is suitable for determining the content of molybdenum, phosphorus, silicon, tin or copper in the ferromolybdenum alloy by X-ray fluorescence melting method, and the preparation method comprises:

[0037] Add anhydrous lithium tetraborate, ferromolybdenum, sodium nitrate and lithium carbonate into the container; then add a release agent for the first time for pre-oxidation treatment;

[0038] Perform first-stage melting followed by cooling to room temperature;

[0039] The second stage of melting is performed after the second release agent is added, followed by cooling.

[0040] Further, in some embodiments, the container needs to be pretreated, including:

[0041] Add lithium tetraborate into the container, then heat-treat at 950±20°C for 180-200s, take out the container and rotate it to hang on the wall, after 30-50s, heat it at 950±20°C for 30-50s, then take out the container and rotate it ag...

Embodiment 1

[0096] This embodiment provides a ferromolybdenum sample, which is mainly prepared through the following steps:

[0097] 1. Preparation of chemical reagents

[0098] Unless otherwise stated in the analysis, the approved reagents of analytical grade and the third-grade water in accordance with GB / T6682 were used.

[0099] Anhydrous lithium tetraborate: solid.

[0100] Lithium carbonate: solid.

[0102] Lithium bromide solution (1000g / L): Slowly add 100g of lithium bromide solid into a beaker pre-filled with 40mL of distilled water (stir while adding the reagent), stir for 2-3min after adding the reagent, add 50mL of water, and continue to stir until the reagent is completely Dissolve, cool to room temperature, dilute with water to 100mL, store in a reagent bottle for later use.

[0103] 2 Instruments and utensils

[0104] X-ray fluorescence spectrometer; high-frequency melting furnace; platinum-yellow crucible (material 95%Pt-5%Au); crucible...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com