Composite wrapping powder and application thereof

A technology of coating flour and starch milk, which is applied in composite coating and its application field, which can solve the problems of separation of flour and meat, and achieve the effects of low gelatinization temperature, good water retention performance, cohesiveness and fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

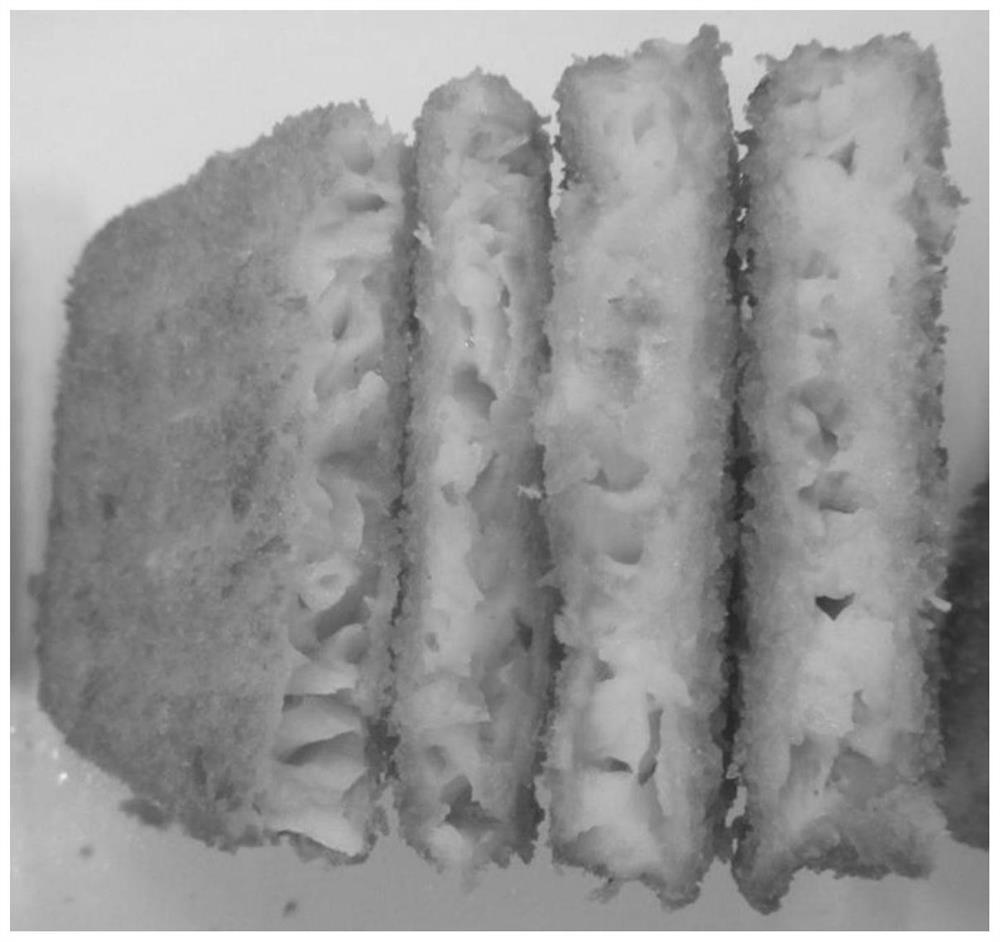

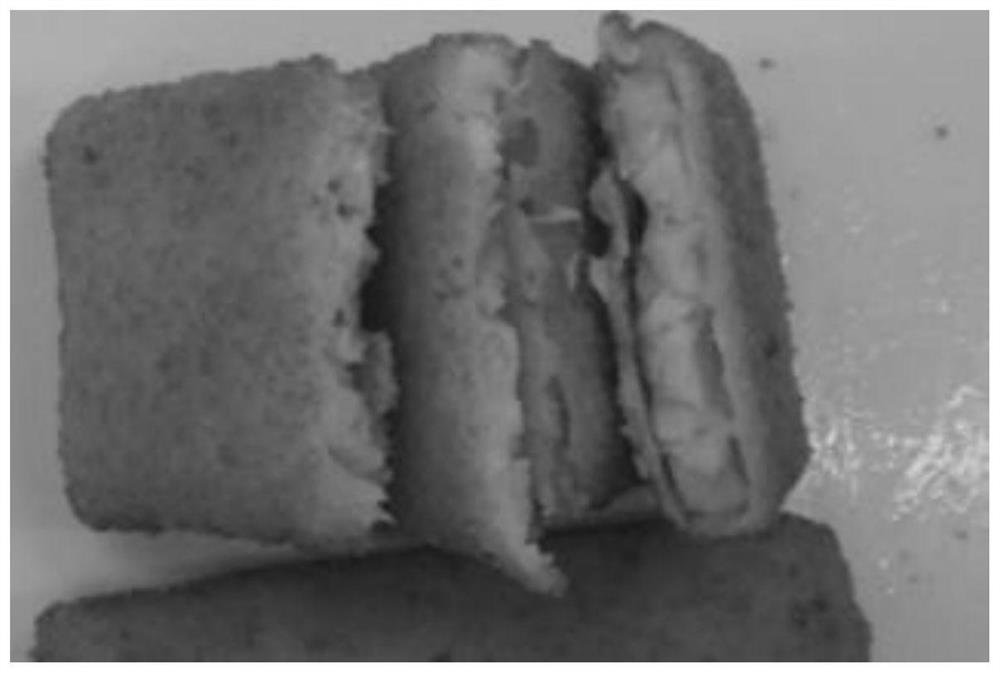

Image

Examples

Embodiment 1

[0029] This embodiment provides a composite breading, which is obtained by mixing corn oxidized starch and tapioca acetate starch in a mass ratio of 1:1.

[0030] Wherein, corn oxidized starch is obtained by following method: the corn starch emulsion that water content is 20wt% is mixed with the concentrated hydrochloric acid that substance concentration is 0.2mol / L, then adds the hydrogen peroxide that volume concentration is 28%, at 60 ℃ Ultrasonic treatment at 400W for 90 minutes, neutralizing pH, centrifugal washing, drying and crushing, and sieving to obtain corn oxidized starch;

[0031] Acetate starch is obtained by the following method: mixing the raw starch emulsion with a water content of 55 wt% and sodium hydroxide solution for activation treatment, then adding acetic anhydride, reacting at 35°C and pH 9 for 3 hours, neutralizing the pH, Centrifugal washing, drying and crushing, and sieving to obtain the acetate starch;

[0032] Wherein, the mass ratio of the aceti...

Embodiment 2

[0035] This embodiment provides a composite breading, which is obtained by mixing corn oxidized starch and tapioca acetate starch in a mass ratio of 3:1.

[0036] The preparation process of corn oxidized starch and tapioca acetate starch is identical with embodiment 1 in the present embodiment;

[0037] The slurry proportioning of present embodiment is identical with embodiment 1.

Embodiment 3

[0039] This embodiment provides a composite breading, which is obtained by mixing corn oxidized starch and tapioca acetate starch in a mass ratio of 3:9.

[0040] The preparation process of corn oxidized starch and tapioca acetate starch is identical with embodiment 1 in the present embodiment;

[0041] The slurry proportioning of present embodiment is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com