A copper-based composite material with high thermal conductivity and adjustable thermal expansion and its preparation method

A copper-based composite material and composite material technology, which is applied in metal material coating technology, metal processing equipment, liquid chemical plating and other directions, can solve the problems of reduced size and structural stability, achieve good electrical and thermal conductivity, and solve thermal problems. Mismatch and effect of high thermal conductivity, dimensional and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a method for preparing a copper-based composite material with high thermal conductivity and adjustable thermal expansion, which includes the following steps:

[0033] Step S101, grind the negative expansion reinforcement particles and the Cu matrix particles according to the molar ratio for more than 0.5h, and make them fully mixed;

[0034] In step S102, the composite powder prepared in step S101 is sintered at 400-900°C to finally obtain the copper-based composite material with high thermal conductivity and adjustable thermal expansion.

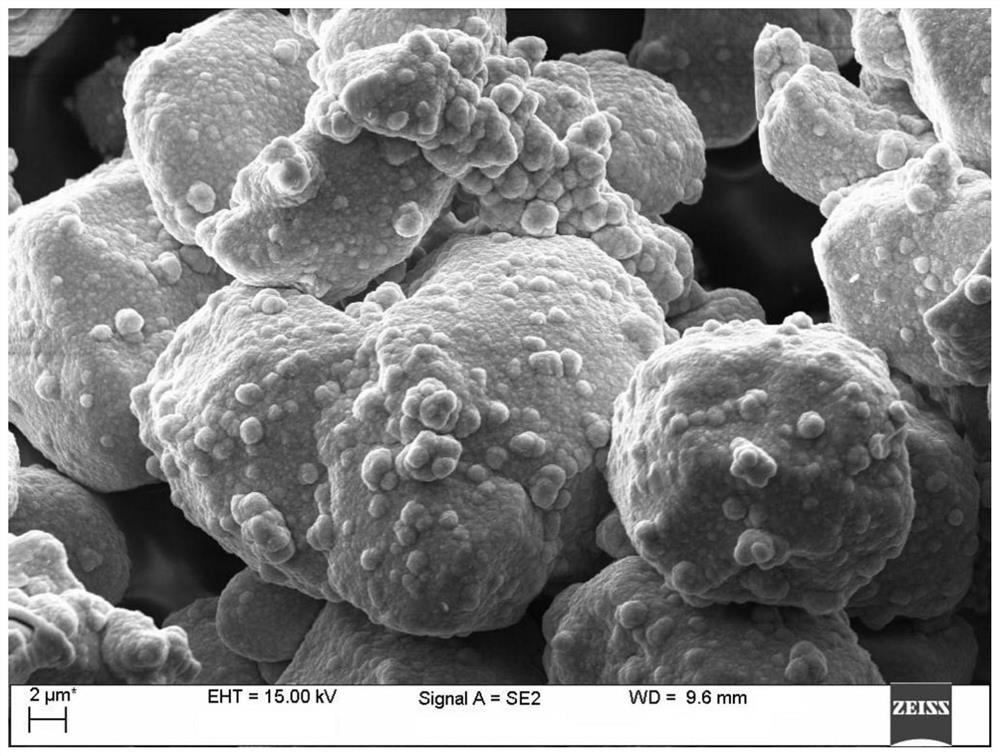

[0035] The present invention also provides a method for preparing a copper-based composite material with high thermal conductivity and adjustable thermal expansion. The electroless copper plating process is used to prepare the Cu-coated negative expansion particle composite material, which improves the chemical compatibility and interface wetting of the negative expansion particle and the Cu matrix....

Embodiment 1

[0046] This embodiment provides a method for preparing a high thermal conductivity zero-expansion copper-based composite material, comprising the following steps:

[0047] Step S211, the ScF 3 The particles are subjected to chemical coarsening, sensitization, and activation pretreatment in sequence;

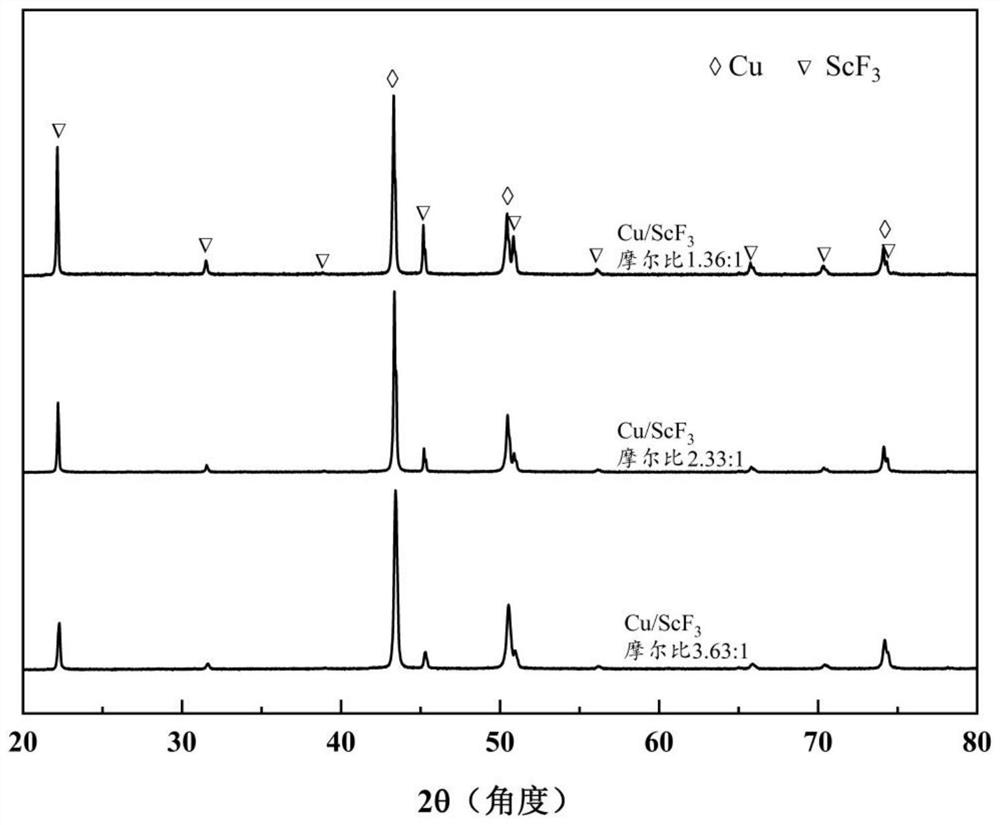

[0048] In step S212, the preprocessed ScF 3 Powder according to Cu / ScF 3 Put the molar ratio of 1.36:1 into the electroless copper plating solution, control the temperature at about 50°C, and then add NaOH solution to the plating solution to stabilize the pH value of the plating solution at about 10. After 0.5 hours of chemical reaction, the electroless copper plating is completed cladding;

[0049] Step S213, the copper-coated ScF prepared in step S212 3 The composite powder is sintered at 700°C to obtain a high thermal conductivity zero-expansion copper matrix composite material.

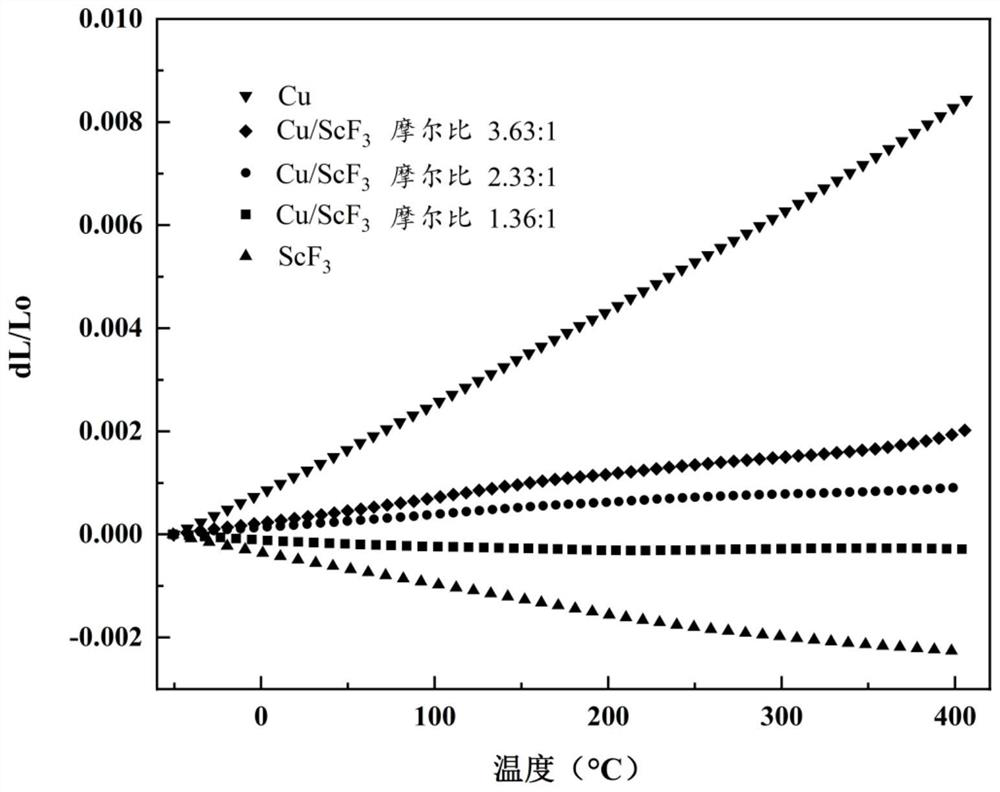

[0050] After testing, the sample has an average thermal expansion coefficient of -0.59×10 in...

Embodiment 2

[0052] This embodiment provides a method for preparing a high thermal conductivity near-zero-expansion copper-based composite material, comprising the following steps:

[0053] Step S221, the ScF 3 The powder is subjected to chemical roughening, sensitization, and activation pretreatment in sequence;

[0054] In step S222, the preprocessed ScF 3 Powder according to Cu / ScF 3 Put the molar ratio 2.33:1 into the electroless copper plating solution, control the temperature at 50°C, and then add NaOH solution to the plating solution to stabilize the pH value of the plating solution at about 10. After 1 hour of chemical reaction, the electroless copper plating is completed. cover;

[0055] Step S223, the copper-coated ScF prepared in step S222 3 The composite powder is sintered at 700°C to obtain a copper-based composite material with high thermal conductivity and near zero expansion.

[0056] After testing, the sample has an average thermal expansion coefficient of 2.02×10 in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com