Extrusion head for pole piece forming, forming device comprising extrusion head and forming method and preparation method of extrusion head

A technology of extrusion device and forming device, which is applied in the field of extrusion heads for forming special-shaped pole pieces, which can solve problems such as difficulty in ensuring the uniformity of pole piece thickness, low flash point of ethanol, powder drop of pole pieces, etc., and achieve excellent liquid absorption capacity , Improve thickness uniformity, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0087] In another specific embodiment, the present invention provides a kind of preparation method of pole piece, and described preparation method comprises:

[0088] The active material, binder and solvent are sequentially mixed, shaped, dried and punched to obtain the pole piece, wherein the forming process is processed by the above forming method.

[0089] Compared with other pole piece preparation methods, the production efficiency of the preparation method provided by the present invention is obviously improved. During the battery assembly process, the carbon sheet can be automatically clamped and assembled by the equipment, and no fine powder will fall off the separator when the current collector is installed, which reduces the risk of micro-short circuit caused by the fine powder of the pole piece. The pole piece mixture is fully kneaded in the screw extruder to further disperse the active material, high specific surface conductive agent, binder and solvent evenly, and ...

Embodiment 1

[0091] This embodiment provides a method for preparing a positive electrode sheet. The preparation method includes sequential mixing, molding, drying and punching, and specifically includes the following steps:

[0092] (1) Mixing: Acetylene black, polytetrafluoroethylene emulsion (solid content is 50wt%) and isopropanol are added into the mixing device according to the mass ratio of 1:0.1:3 for mixing and stirring, and the stirring of the mixing device The paddle speed is 100r / min, stirring for 10min to obtain the pole piece mixture;

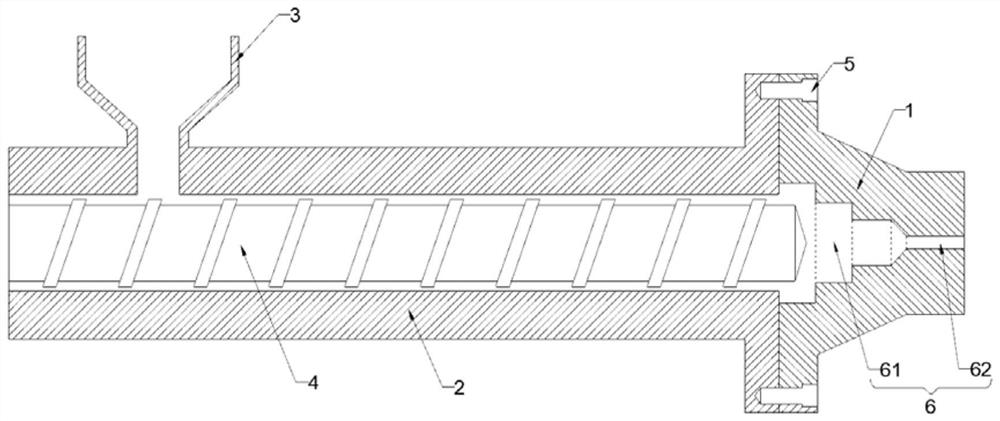

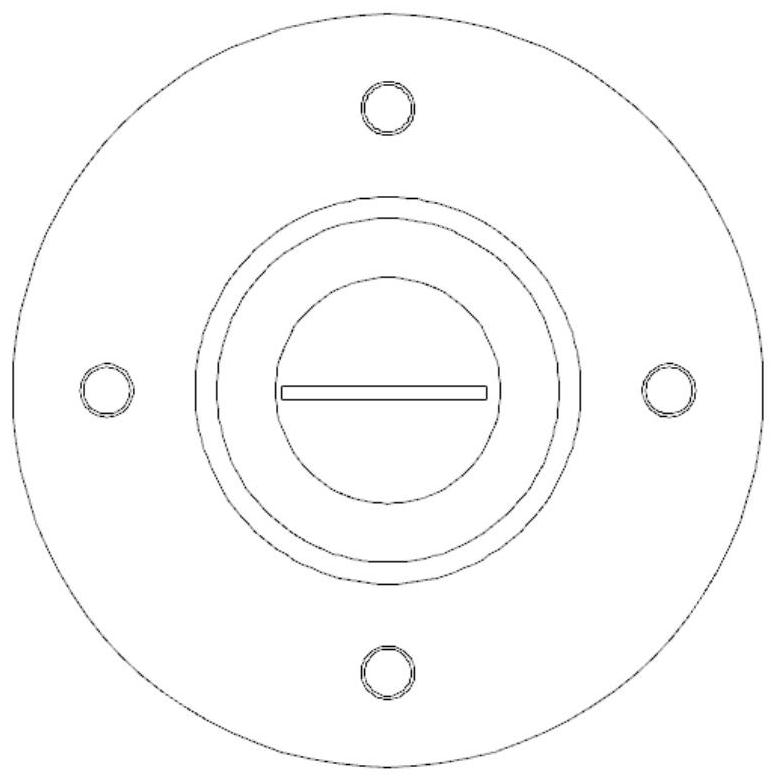

[0093] (2) Forming: the pole piece mixture is added to the feeding bin 3, and is sent into the extrusion device from the feeding bin 3, and the pole piece mixture is further fully mixed through the rotating extrusion of the screw 4, and then pushed out and transported to the extrusion head 1 and Extruded by the extrusion head 1, the extrusion frequency is 30Hz, and the extrusion temperature is 60°C, wherein the extrusion head 1 is as figure 2...

Embodiment 2

[0102] This embodiment provides a method for preparing a positive electrode sheet. The preparation method includes sequential mixing, molding, drying and punching, and specifically includes the following steps:

[0103] (1) Mixing: the positive electrode material, polytetrafluoroethylene emulsion (solid content is 55wt%) and isopropanol are added to the mixing device according to the mass ratio of 1:0.2:4 for mixing and stirring. The positive electrode material includes the mass ratio Be 9:1 acetylene black and Ketjen black, the stirring paddle speed of the mixing device is 200r / min, stir 7min to obtain pole piece mixing;

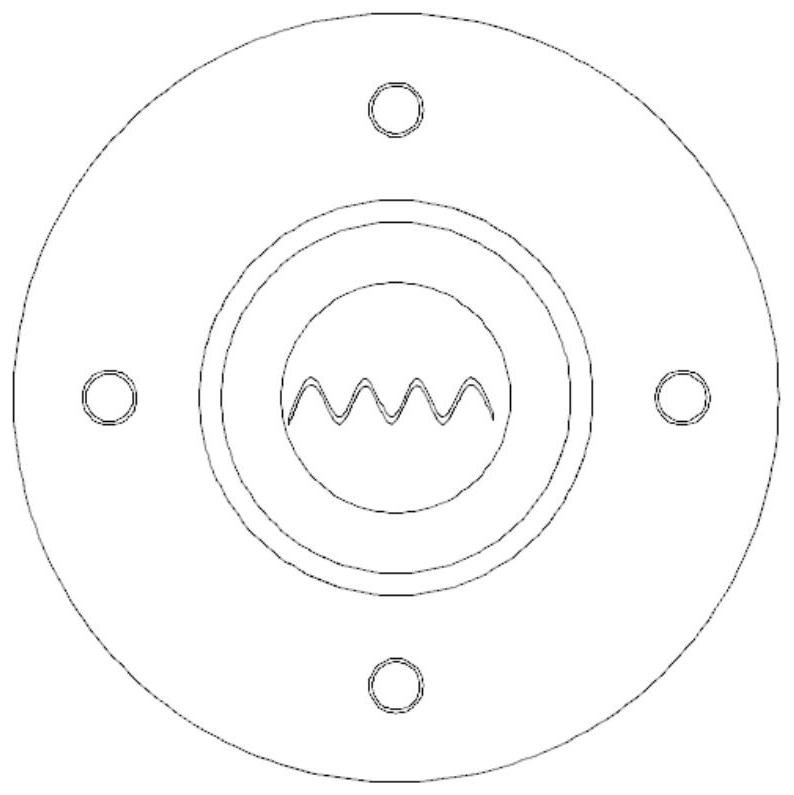

[0104] (2) Forming: the pole piece mixture is added to the feeding bin 3, and is sent into the extrusion device from the feeding bin 3, and the pole piece mixture is further fully mixed through the rotating extrusion of the screw 4, and then pushed out and transported to the extrusion head 1 and Extruded by the extrusion head 1, the extrusion frequency is 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com