Preparation method and application of cobalt diselenide/carbon-based flexible electrode material with interface enhancement structure

A technology of cobalt diselenide and interface enhancement, which is applied in the direction of fuel cell half-cells and secondary battery-type half-cells, battery electrodes, structural parts, etc., can solve the problems of electrochemical performance degradation and easy damage, and achieve The effect of increasing the contact area, enhancing stability, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Hydrophilicize the carbon cloth: cut the carbon cloth into 3 x 3 cm 2 size, add concentrated nitric acid, and treat at 80°C for 4 hours;

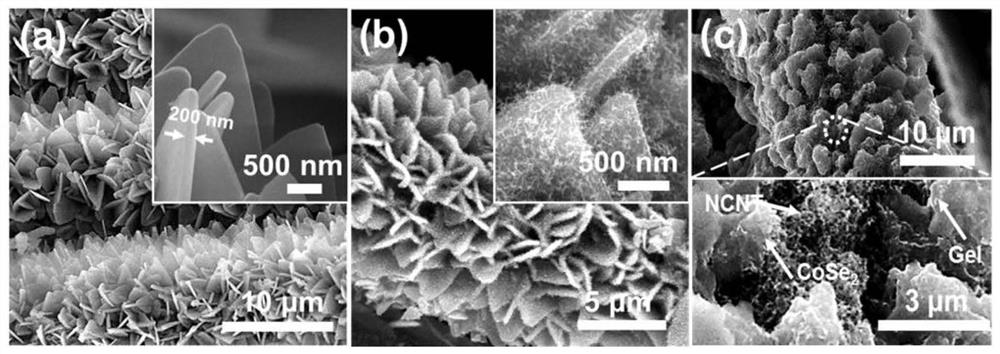

[0036] (2) Weigh 1.3136 g of 2-methylimidazole dissolved in 40 mL of deionized water, denoted as A; weigh 0.582 g of Co(NO 3 ) 2 ·6H 2 O was dissolved in 40 mL deionized water, which was denoted as B; Pour A into B and stir evenly, then add hydrophilic carbon cloth, and let it stand for 4 hours to obtain the Co-MOF@CC composite material, the SEM image of which is as follows figure 1 (a) Shown: the obtained 2D Co-MOF presents a 2D triangular sheet with a thickness of about 200 nm;

[0037] (3) Put Co-MOF@CC in a tube furnace, N 2 Under atmosphere, heat up to 500°C at 5°C / min, pass through ethanol, H 2 , calcined for 20 min, Co / N-CNT@CC composite material;

[0038] (4) Put Co / N-CNT@CC in a tube furnace, add 0.6g selenium powder, N 2 Under the atmosphere, the temperature is raised to 450°C at 10°C / min, and selenized for 2h to...

Embodiment 2

[0042] (1) Hydrophilicize the carbon cloth: cut the carbon cloth into 3 x 3 cm 2 size, add concentrated nitric acid, and treat at 75°C for 5 hours;

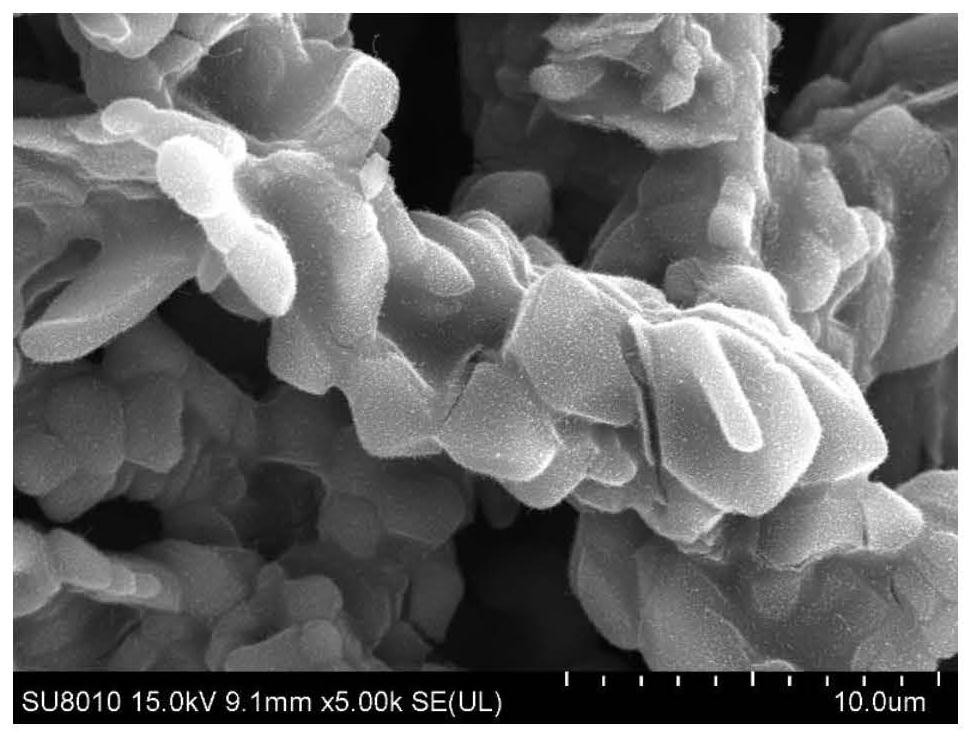

[0043] (2) Weigh 1.3136 g of 2-methylimidazole dissolved in 40 mL of deionized water, denoted as A; weigh 0.582 g of Co(NO 3 ) 2 ·6H 2O, 0.075g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 40 mL of deionized water, denoted as B; A was poured into B and stirred evenly, then hydrophilized carbon cloth was added, and left to stand for 4 h to obtain a Co(Zn)-MOF@CC composite material, the SEM image of which was shown image 3 Shown: The obtained two-dimensional Co(Zn)-MOF presents two-dimensional triangular flakes;

[0044] (3) Put Co(Zn)-MOF@CC in a tube furnace, N 2 Under the atmosphere, heat up to 300°C at 5°C / min, pass through ethanol, H 2 , calcined for 20min, Co(Zn) / N-CNT@CC composite material;

[0045] (4) Put Co(Zn) / N-CNT@CC in a tube furnace, add 0.45 g of selenium powder, N 2 Under the atmosphere, the temperature was rais...

Embodiment 3

[0049] (1) Hydrophilicize the carbon cloth: cut the carbon cloth into 3 x 3 cm 2 size, add concentrated nitric acid, and treat at 85°C for 4 hours;

[0050] (2) Weigh 1.3136 g of 2-methylimidazole dissolved in 40 mL of deionized water, denoted as A; weigh 0.582 g of Co(NO 3 ) 2 ·6H 2 O, 0.073g Ni(NO 3 ) 2 ·6H 2 O was dissolved in 40 mL of deionized water, denoted as B; A was poured into B and stirred evenly, then hydrophilized carbon cloth was added, and left to stand for 4 h to obtain the Co(Ni)-MOF@CC composite material, the SEM image of which was shown Figure 4 Shown: The obtained two-dimensional Co(Ni)-MOF presents a two-dimensional triangular sheet;

[0051] (3) Put Co(Ni)-MOF@CC in a tube furnace, N 2 Under the atmosphere, heat up to 800°C at 5°C / min, pass through ethanol, H 2 , calcined for 20min, Co(Ni) / N-CNT@CC composite material;

[0052] (4) Put Co(Ni) / N-CNT@CC in a tube furnace, add 0.75 g of selenium powder, N 2 Under the atmosphere, the temperature was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com