Method for recycling diatomite particles in HPB through rotational flow

A technology of diatomite particles and diatomite, which is applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problems of lack of simple operation control and shortening, and achieve the goal of overcoming degassing Effects of conflicting sludge age between nitrogen and phosphorus removal bacteria, avoiding accumulation, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

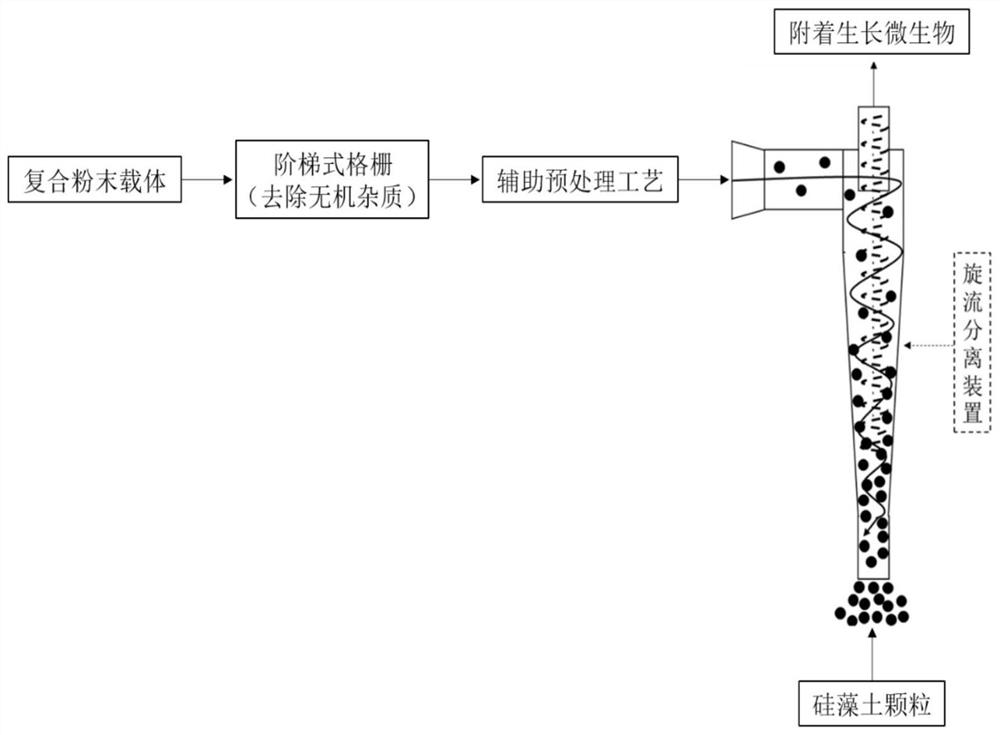

[0024] The technical method of present embodiment swirl recovery diatomite may further comprise the steps:

[0025] (1) The effluent of the secondary sedimentation tank containing diatomite particles is removed through the pre-stepped fine grid to remove inorganic impurities; the composite powder carrier is subjected to centrifugation pretreatment with a centrifugal force of 500g and a centrifugation time of 3min; The biofilm attached to the algae earth is effectively gradiently stripped; then, the sludge mixture is sent tangentially from the inlet into the cyclone cylindrical part of the cyclone, and a high-speed rotary motion is formed in the cylinder to generate a centrifugal force field. The diatomite particles with a larger particle size of 55 μm in the lower mixture undergo centrifugal sedimentation, are thrown to the wall of the vessel to lose kinetic energy, swirl downward under the action of gravity, and are discharged through the underflow outlet; the activated sludge...

Embodiment 2

[0030] (1) The effluent of the secondary sedimentation tank containing diatomite particles is removed through the pre-stepped fine grid to remove inorganic impurities; the composite powder carrier is subjected to centrifugal pretreatment with a centrifugal force of 600g and a centrifugal time of 2min; The biofilm attached to the algae earth is effectively gradiently stripped; then, the sludge mixture is sent tangentially from the inlet into the cyclone cylindrical part of the cyclone, and a high-speed rotary motion is formed in the cylinder to generate a centrifugal force field. The diatomite particles with a larger particle size of 50 μm in the lower mixture undergo centrifugal sedimentation, are thrown to the wall of the vessel to lose kinetic energy, swirl downward under the action of gravity, and are discharged through the underflow outlet; the quality of activated sludge particles is low, Under less centrifugal force, it is located in the central area of the cyclone sepa...

Embodiment 3

[0035] (1) The effluent of the secondary sedimentation tank containing diatomite particles is removed through the pre-stepped fine grid to remove inorganic impurities; the composite powder carrier is subjected to centrifugation pretreatment with a centrifugal force of 700g and a centrifugation time of 1min; The biofilm attached to the algae earth is effectively gradiently stripped; then, the sludge mixture is sent tangentially from the inlet into the cyclone cylindrical part of the cyclone, and a high-speed rotary motion is formed in the cylinder to generate a centrifugal force field. The diatomite particles with a larger particle size of 55 μm in the lower mixture undergo centrifugal sedimentation, are thrown to the wall of the vessel to lose kinetic energy, swirl downward under the action of gravity, and are discharged through the underflow outlet; the activated sludge particles are of low quality, Under less centrifugal force, it is located in the central area of the cyclo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com