Polyethylene and preparation method thereof

A polyethylene and copolymer technology, applied in the field of polyethylene and its preparation, can solve the problem of insufficient branching degree and achieve the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

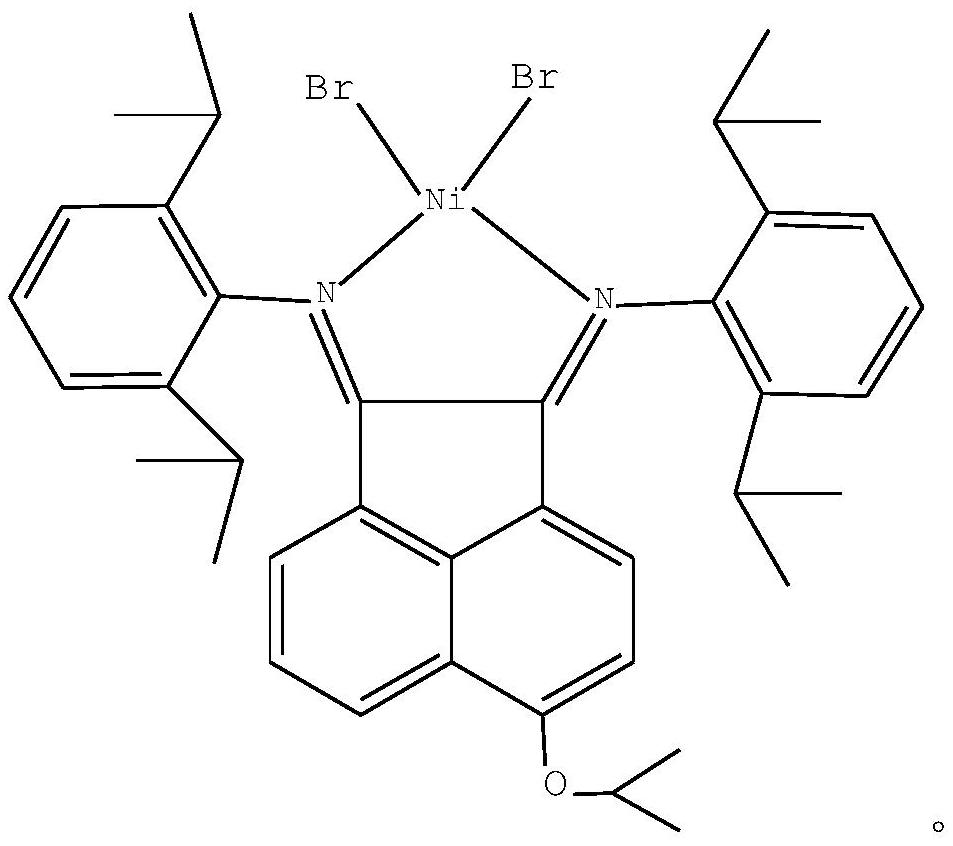

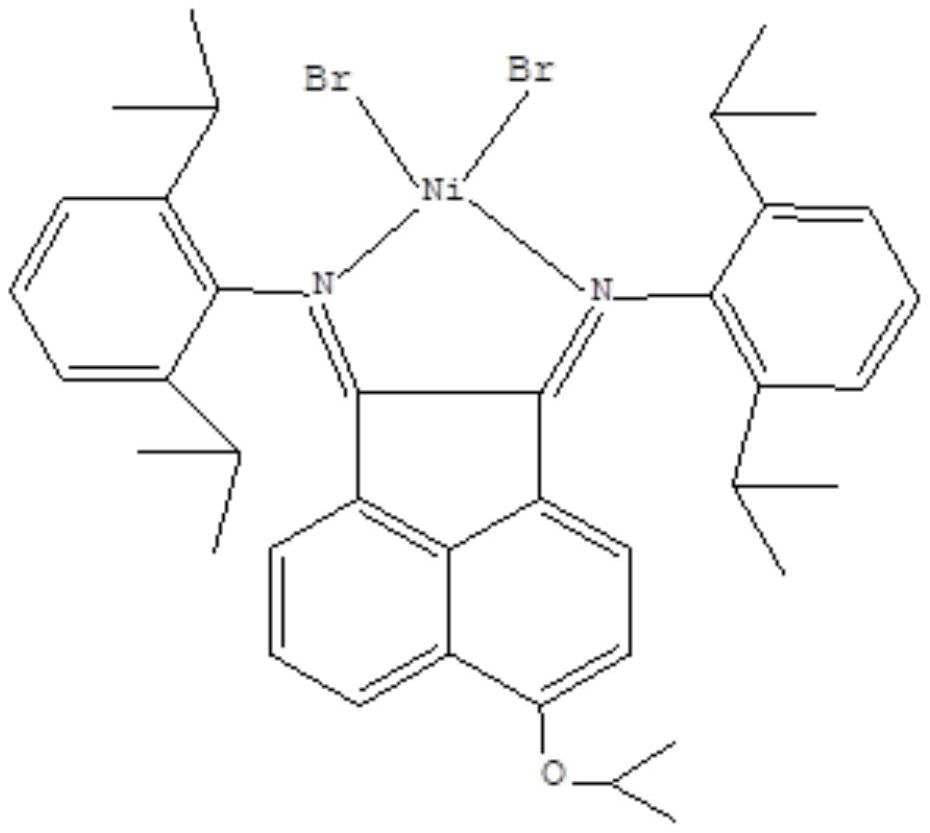

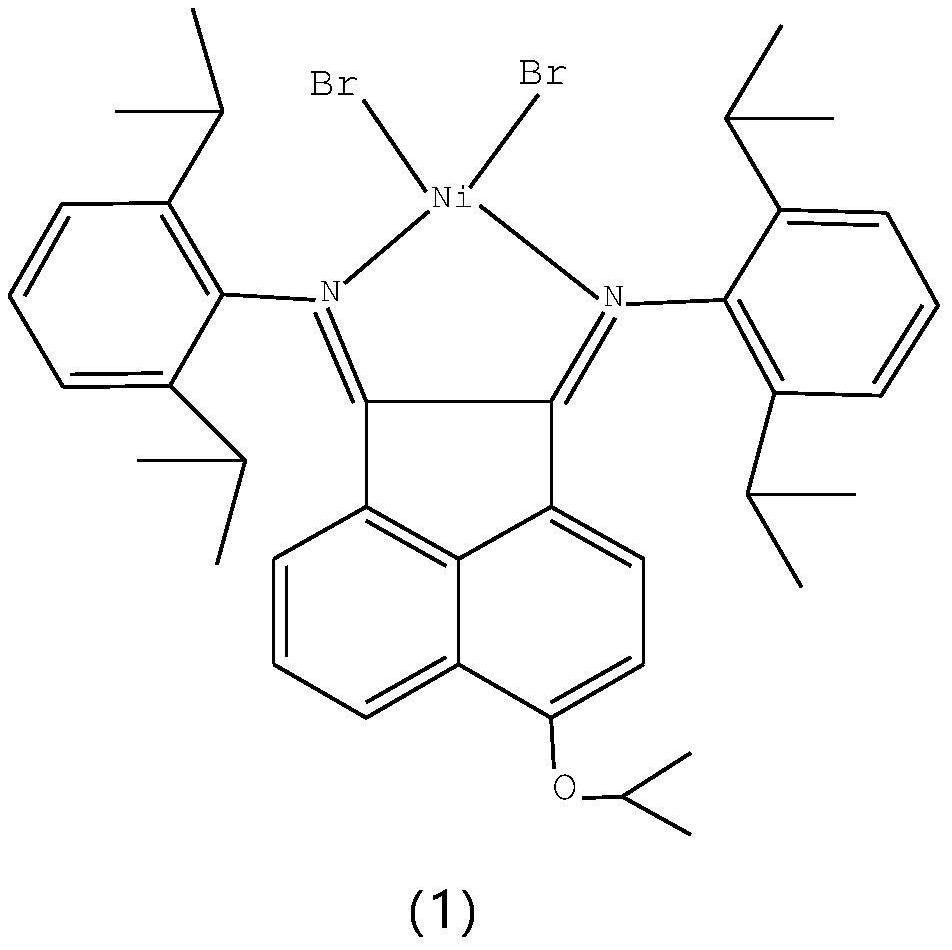

[0024] Add the ethylene raw material into a 500ml reaction kettle with a stirring device, a temperature control system, a pressure control system, and a feeding system (make sure the reaction system is in an anhydrous and oxygen-free environment before use), maintain the pressure at 0.1MPa, and control the temperature at 50°C , successively add cocatalyst 0.7mmolMAO (Al / Ni=75), the toluene solution 5μmol (concentration 0.1mmol / L) of main catalyst formula (1) adjusts the ethylene pressure in the reactor to the required polymerization pressure 0.4MPa, starts the polymerization reaction. The polymerization reaction was terminated after 4 h, and the obtained polymer solution was deactivated with a volume fraction of 5% hydrochloric acid / ethanol solution (the volume ratio of hydrochloric acid to ethanol was 5%, and the concentration of hydrochloric acid was 1 mol / L) to deactivate the catalyst and remove the solvent, The obtained polymer was placed in a vacuum drying oven at 60°C and...

Embodiment 2

[0027] The polymerization conditions were the same as those in Example 1, except that MMAO was replaced by MAO. Obtained branched polyethylene product 21.5g, catalyst activity 4.3x10 6 g / (mol Ni·h).

[0028] Using 1,2,4-trichlorobenzene as a solvent, the Mw of the product was 23.92x10 tested by high temperature gel chromatography-Fourier infrared spectroscopy at 150℃. 4 g / mol with a branch content of 123.4 CH 3 / 1000C. Take a 50mg sample and analyze it with analytical TREF. The analysis result shows that the mass fraction of the elution component within 40°C is 62.16%, and the density is 0.891g / cm 3 .

Embodiment 3

[0030] The polymerization conditions are the same as in Example 1, except that MMAO is only replaced by MAO, and the polymerization pressure is controlled to be 1.5MPa to obtain 25.5g of branched polyethylene products, and the catalyst activity is 5.1×10. 6 g / (mol Ni·h). Using 1,2,4-trichlorobenzene as a solvent, the Mw of the product was 28.35x10 tested by high temperature gel chromatography-Fourier infrared spectroscopy at 150°C. 4 g / mol, the branched chain content is 152.7 CH 3 / 1000C. Take 50 mg of sample and analyze it with analytical TREF. The analysis result shows that the mass fraction of elution components within 40°C is 68.41%, and the density is 0.889g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com