Preparation method of nano-cellulose-induced titanium dioxide composite ultraviolet shielding material

A nanocellulose, titanium dioxide technology, applied in the direction of radiation-absorbing coatings, etc., can solve the problems of insufficient stability of coated composite nanoparticles, poor solvent dispersion of the matrix, insufficient stability, etc., to improve the anti-ultraviolet ability and improve the ultraviolet Shielding effect, effect of improving stability and key energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

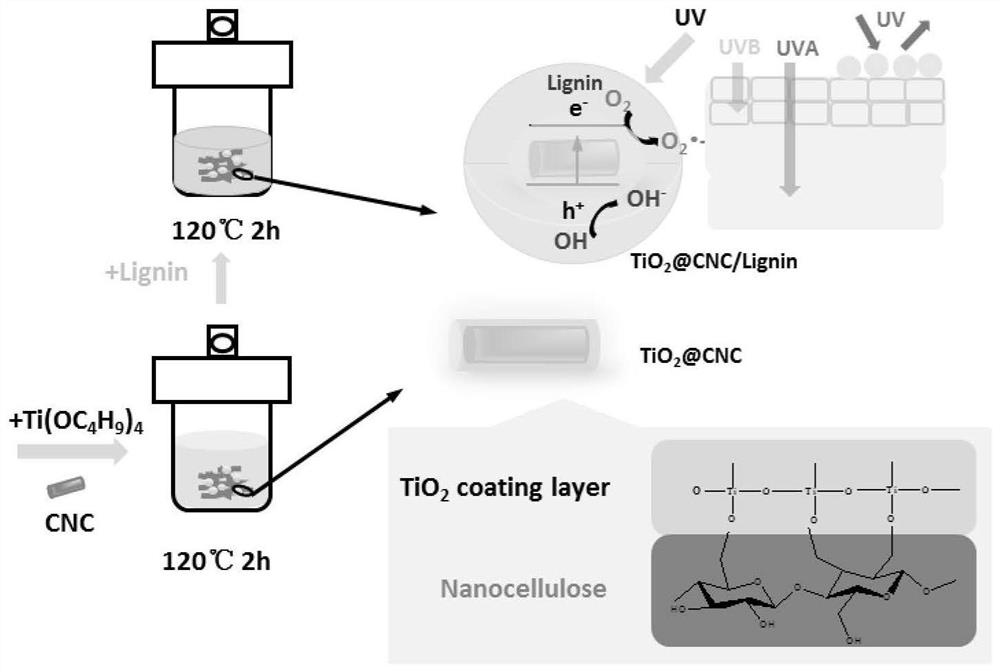

[0027] Embodiment 1: A preparation method of nanocellulose-induced titanium dioxide composite ultraviolet shielding material, carried out according to the following steps:

[0028] a, adding 0.8g of sodium lignosulfonate to 15mL of mass concentration by mass is 0.8% nanocellulose suspension (nanocellulose is called CNC for short, is a kind of macromolecule material from natural fibers, nontoxic and nontoxic The irritating smell is a linear polymer composed of glucosyl groups and β-1,4-glycosidic bonds), stir to mix and disperse, then add 20ml of absolute ethanol, stir rapidly for 6 minutes, and then heat up to 75°C. Keep stirring for 27 minutes to obtain the nanocellulose template induction reagent;

[0029]b. Add 4 mL of butyl titanate to the nanocellulose template induction reagent, stir during the dropwise addition, and continue to stir for 23 minutes after the dropwise addition to form a mixed solution of the titanium dioxide precursor and the template induction reagent; ...

Embodiment 2

[0032] Embodiment 2: A preparation method of nanocellulose-induced titanium dioxide composite ultraviolet shielding material, carried out according to the following steps:

[0033] a. Add 0.4 g of sodium lignosulfonate in parts by mass to 10 mL of nanocellulose suspension with a mass concentration of 1.2%, stir to mix and disperse, then add 30 ml of absolute ethanol, stir rapidly for 4 minutes, and then heat up to 90°C, keep stirring for 20 minutes to obtain a nanocellulose template-induced reaction agent;

[0034] b. Add 6 mL of butyl titanate to the nanocellulose template induction reagent, stir during the dropwise addition, and continue stirring for 18 minutes after the dropwise addition to form a mixed solution of the titanium dioxide precursor and the template induction reagent;

[0035] c. Slowly add 2ml of sulfuric acid solution with a mass concentration of 23% dropwise into the mixed solution of the above-mentioned titanium dioxide precursor and the template-inducing r...

Embodiment 3

[0036] Embodiment 3: A preparation method of nanocellulose-induced titanium dioxide composite ultraviolet shielding material, carried out according to the following steps:

[0037] a. Add 0.5 g of sodium lignosulfonate in parts by mass to 10 mL of nanocellulose suspension with a mass concentration of 1%, stir to mix and disperse, then add 25 ml of absolute ethanol, stir rapidly for 5 minutes, and then heat up to 80°C, keep stirring for 30 minutes, and finally obtain the nanocellulose template induction reaction agent; add perfluorooctyltrichlorosilane during the stirring process, so that after the nanocellulose is modified by the reaction of perfluorooctyltrichlorosilane, as Figure 7 As shown, a nanocluster is attached to the surface of sodium lignosulfonate, and the nanocluster is used to improve the stability and bond energy of the chemical bond formed by the oxygen-containing functional group of lignin and the titanium dioxide precursor, so as to subsequently increase the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com