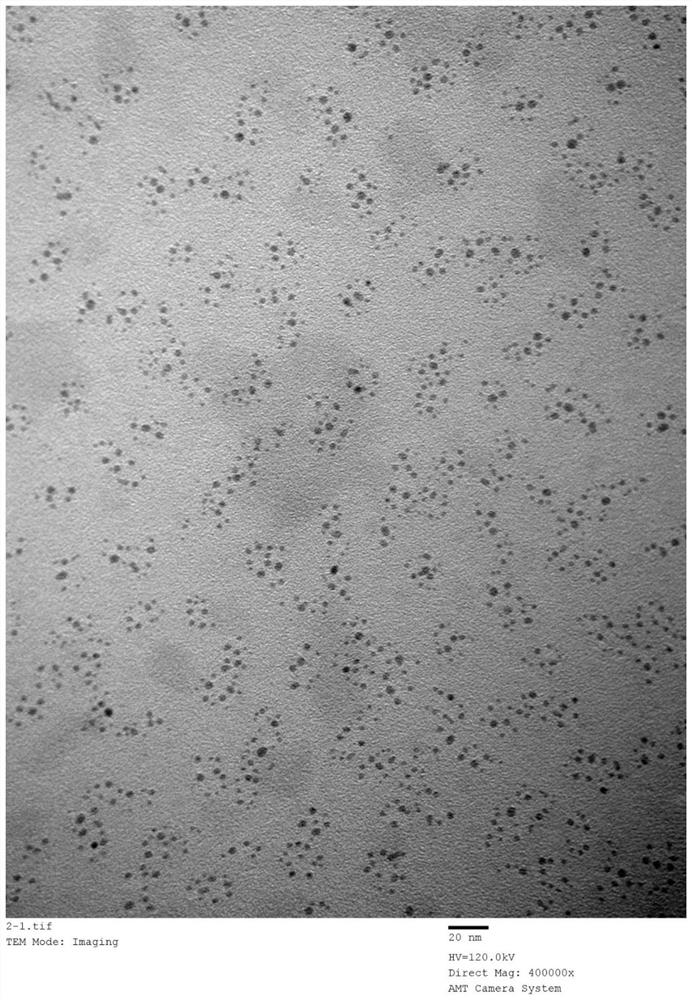

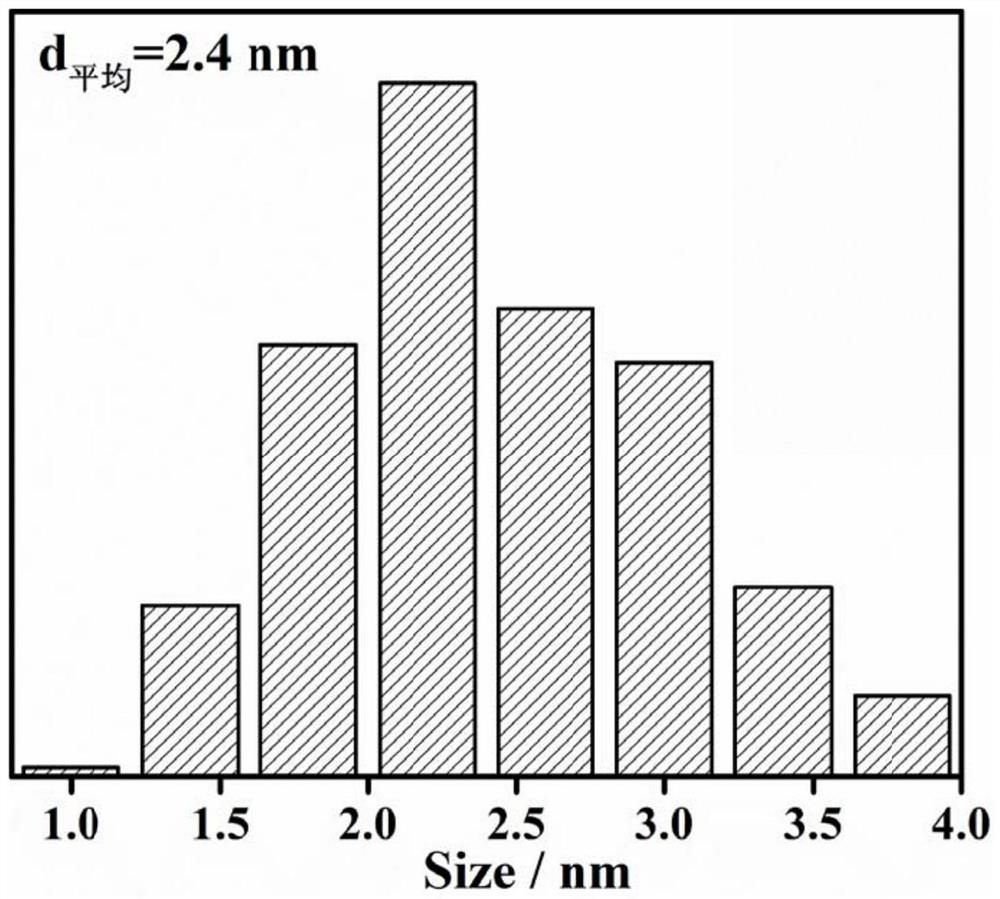

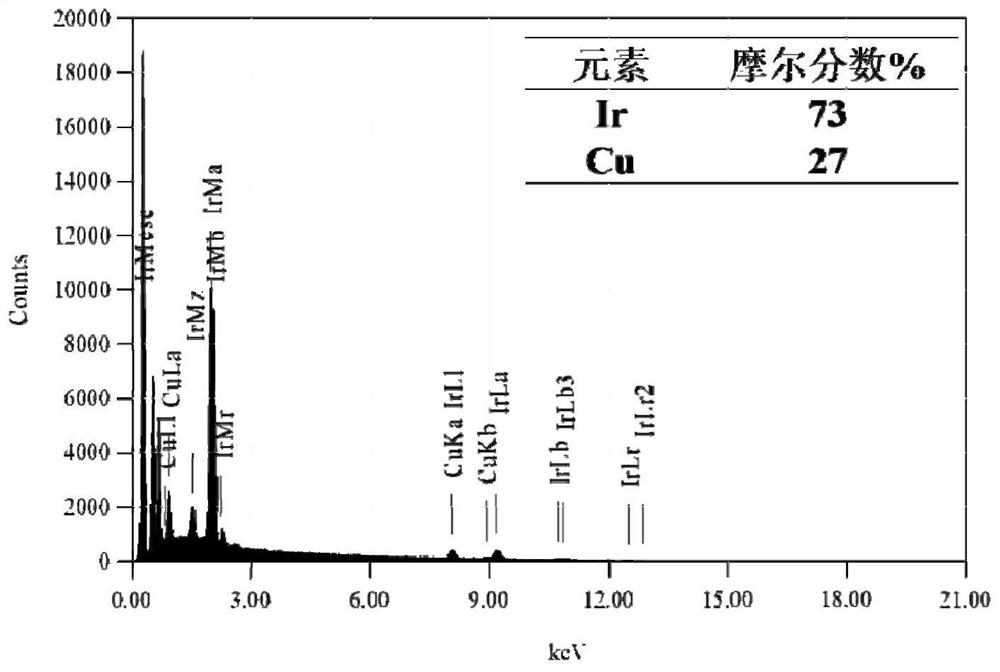

Mono-dispersed IrCu alloy catalyst as well as preparation method and application thereof

A technology of alloy catalyst and solvent, which is applied in the field of electrocatalysis, can solve problems such as reduction, achieve the effects of reducing reaction temperature, excellent OER activity, and improving catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Accurately weigh 0.00559g CuBr 2 (0.025mmol), dissolved in 3.5mL deionized water, added 0.5mLH 2 IrCl 6 (0.05mol / L) and stir at room temperature for 0.5h;

[0031] (2) Accurately weigh 0.01682g Na 2 h 2 P 2 o 7 (0.075mmol) was dissolved in 1mL deionized water, added dropwise to the solution in (1), and stirred at room temperature for 0.5h;

[0032] (3) Add 5mL of ethylene glycol to make H 2 The volume ratio of O and EG is 1:1, stirring at room temperature for 0.5h;

[0033] (4) Move the solution in (3) into an 80°C oil pan and stir for 12.0 hours;

[0034] (5) add ethanol and centrifuge, and then wash 4 times with a mixed solution of deionized water and ethanol to obtain IrCu nanoparticles.

Embodiment 2

[0036] (1) Accurately weigh 0.00559g CuBr 2 (0.025mmol), dissolved in 3.5mL deionized water, added 0.5mLH 2 IrCl 6 (0.05mol / L) and stir at room temperature for 0.5h;

[0037] (2) Accurately weigh 0.01682g Na 2 h 2 P 2 o 7 (0.075mmol) was dissolved in 1mL deionized water, added dropwise to the solution in (1), and stirred at room temperature for 0.5h;

[0038] (3) Add 5mL of ethylene glycol to make H 2 The volume ratio of O and EG is 1:1, stirring at room temperature for 0.5h;

[0039] (4) Move the solution in (3) into a 110°C oil pan and stir for 3.0 hours;

[0040] (5) add ethanol and centrifuge, and then wash 4 times with a mixed solution of deionized water and ethanol to obtain IrCu nanoparticles.

Embodiment 3

[0042] (1) Accurately weigh 0.00559g CuBr 2 (0.025mmol), dissolved in 0.25mL deionized water, added 0.5mLH 2 IrCl 6 (0.05mol / L) and stir at room temperature for 0.5h;

[0043] (2) Accurately weigh 0.01682g Na 2 h 2 P 2 o 7 (0.075mmol) was dissolved in 1mL deionized water, added dropwise to the solution in (1), and stirred at room temperature for 0.5h;

[0044] (3) Add 5mL of ethylene glycol to make H 2 The volume ratio of O and EG is 1:1, stirring at room temperature for 0.5h;

[0045] (4) Move the solution in (3) into a 140°C oil pan and stir for 0.1h;

[0046](5) add ethanol and centrifuge, and then wash 4 times with a mixed solution of deionized water and ethanol to obtain IrCu nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com