Method for rapidly preparing highly-regular porous anodic aluminum oxide template

A technology of alumina template and porous anode, which is applied in the field of electrochemistry, can solve problems such as breakdown and electrolyte heating, and achieve the effect of rapid preparation and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

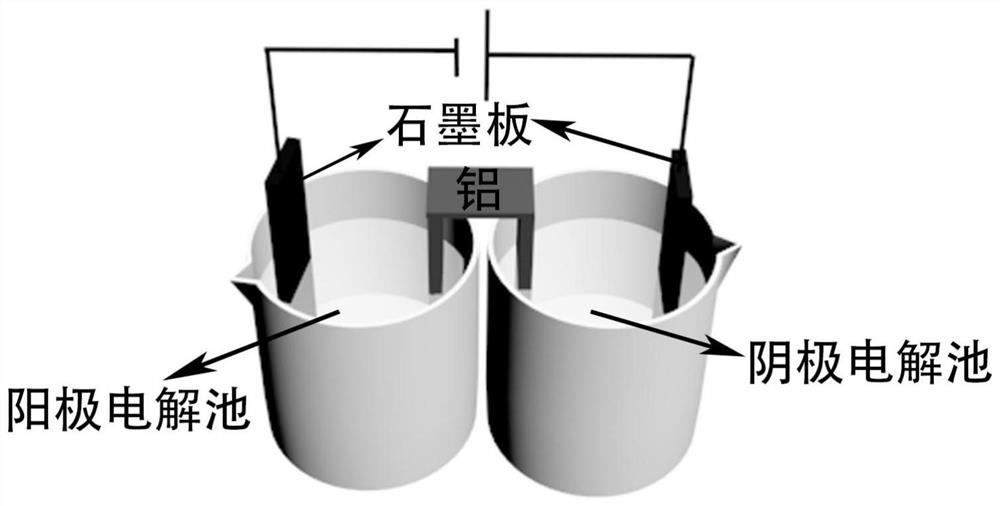

Embodiment 1

[0020] Electrochemical polishing was performed on both sides of a 200 μm thick aluminum foil, including the following steps: (1) soaking in 2 wt% NaOH solution for 2 minutes; wt% H 3 PO 4 , 12 wt% CrO 3 , 8wt% H 2 Constant current electrochemical polishing was performed in a mixed solution of O for 2 minutes at a current density of 120 mA cm -2 , and then rinsed with deionized water. The polished aluminum sheet is folded into an inverted "U" shape, and the two ends of the aluminum sheet are respectively inserted into two independent electrolytic cells. A graphite plate is inserted as an electrode in the two electrolytic cells, and the two graphite plates are parallel to the two ends of the inverted "U"-shaped aluminum plate, and the distance is equal, both of which are 0.5 cm. Two graphite plates are connected to the power lines. The electrolytic cell where the graphite plate connected to the negative electrode of the power supply is located is recorded as the anode elec...

Embodiment 2

[0022] Except that the catholyte was 0.75 M sulfuric acid solution, other steps were the same as in Example 1.

Embodiment 3

[0024] Except that the catholyte was 20 wt% ammonium adipate electrolyte, other steps were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com