Mold for preparing tricrystal and preparation method of tricrystal

A mold and seed crystal technology, which is applied in the field of preparing three-crystal molds and three-crystal preparation, can solve the problems of unable to systematically study the three-pronged grain boundary, and the Bridgman crystal growth furnace cannot prepare three-crystal crystals, etc., to achieve simple molds Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

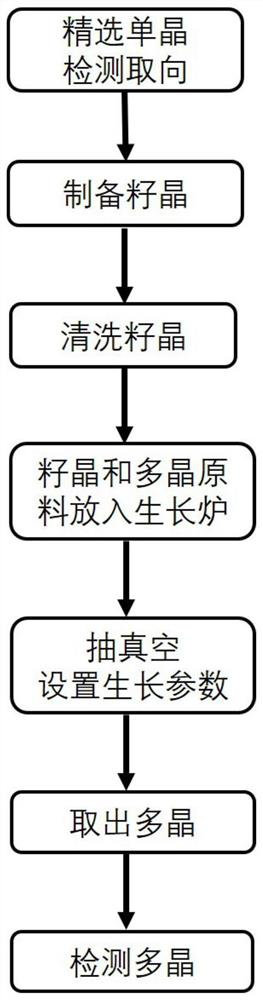

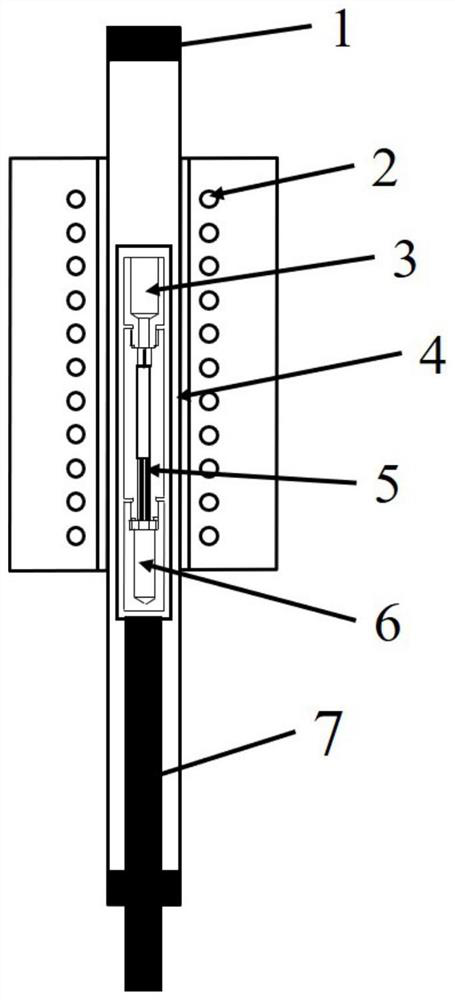

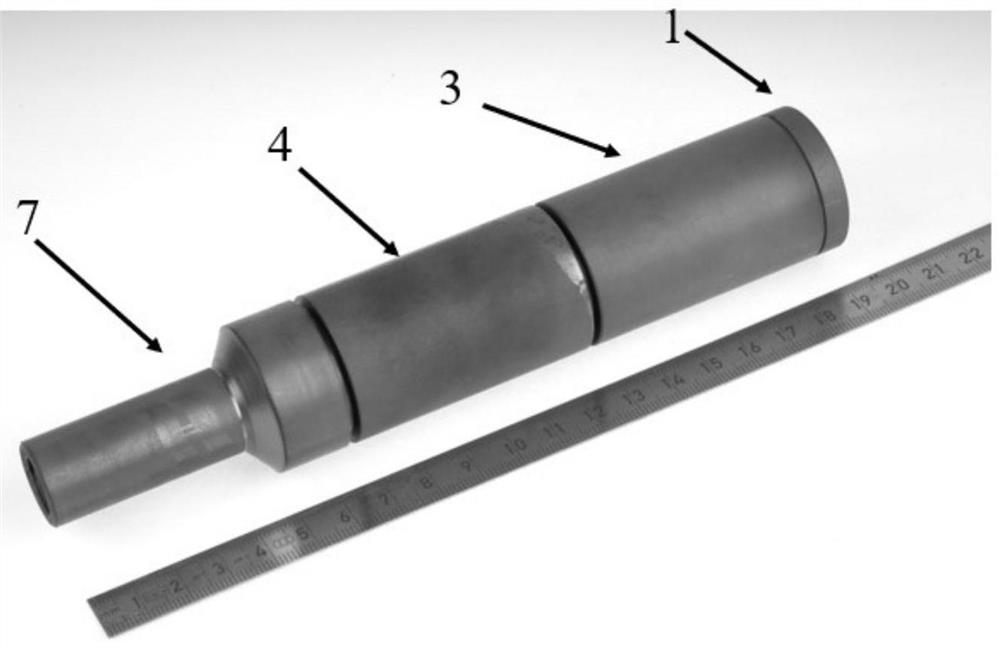

[0061] Such as Figure 1-6 As shown, in a preferred embodiment, the mold and preparation method used for preparing pure Cu triple crystals from pure Cu single crystals are as follows:

[0062] The mold for preparing three crystals of the present invention is used in the core area of the mold in the Bridgman crystal growth furnace, including the furnace wall 4 and the core main body area 5; wherein, the furnace wall 4 is a hollow cylinder, and the furnace wall 4 has two ends. The thread is located outside the core body area 5, and the outer diameter of the furnace wall 4 is 35 mm.

[0063] The core body region 5 includes an outer graphite layer 8 , an inner graphite layer 9 and a seed placement layer 10 .

[0064] The inner graphite layer 9 is the remaining part of an equilateral triangular prism after cutting off six triangular prisms at the center positions of three corners and three side lengths, and is located in the center of the core body area 5. The cross-sectional he...

Embodiment 2

[0076] Such as Figure 1-6 As shown, in a preferred embodiment, the mold and preparation method used to prepare pure Au triple crystals from pure Au single crystals are as follows:

[0077] The mold for preparing the three crystals of the present invention is basically the same as that of Example 1, except that the section height of the inner graphite layer 9 is 6.5 mm.

[0078] In this embodiment, using the above-mentioned mold to prepare pure Au three crystals includes the following steps:

[0079] Step 1: Take out the pure Au single crystal, and use the X-ray Laue method to determine the orientation of the single crystal.

[0080] Step 2: The pure Au single crystal is cut into trapezoidal columns by wire cutting to obtain the pure Au seed crystal. The height of the trapezoidal cross section of the pure Au seed crystal is 0.8 mm.

[0081] Step 3: immerse the pure Au seed crystal in nitric acid solution for 30 minutes, and then wash it with ethanol solution for 10 minutes t...

Embodiment 3

[0087] Such as Figure 1-6 Shown, in a preferred embodiment, by Cu-Ni alloy (2.5at.%Ni) single crystal preparation Cu-Ni alloy (2.5at.%Ni) triple crystal used mold and preparation method are as follows:

[0088] The mold used to prepare the three crystals of the present invention is the same as that in Example 1.

[0089] In this embodiment, the preparation of Cu-Ni alloy (2.5at.%Ni) triple crystals using the above-mentioned mold includes the following steps:

[0090] Step 1: Take out the Cu-Ni alloy (2.5 at.% Ni) single crystal, and judge the orientation of the single crystal by X-ray Laue method.

[0091] Step 2: Cut the Cu-Ni alloy (2.5at.%Ni) single crystal into a trapezoidal columnar body by wire cutting to obtain the Cu-Ni alloy (2.5at.%Ni) seed crystal, and the Cu-Ni alloy (2.5at.%Ni) .% Ni) The height of the trapezoidal section of the seed crystal is 2.5mm.

[0092] Step 3: Put the Cu-Ni alloy (2.5at.%Ni) seed crystal into the nitric acid solution and immerse it for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com