Thermal power plant boiler pulverizing and coal feeding control system and control method thereof

A technology of a control system and a control method, which is applied in the control of combustion, combustion method, supply configuration, etc., can solve problems such as inability to accurately indicate equipment status and parameters, inability to accurately determine the cause of failure, and malfunction of the control system, tripping and shutdown, etc. The effect of reducing personnel maintenance costs and hardware configuration, intuitive equipment parameter detection, and reducing maintenance difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

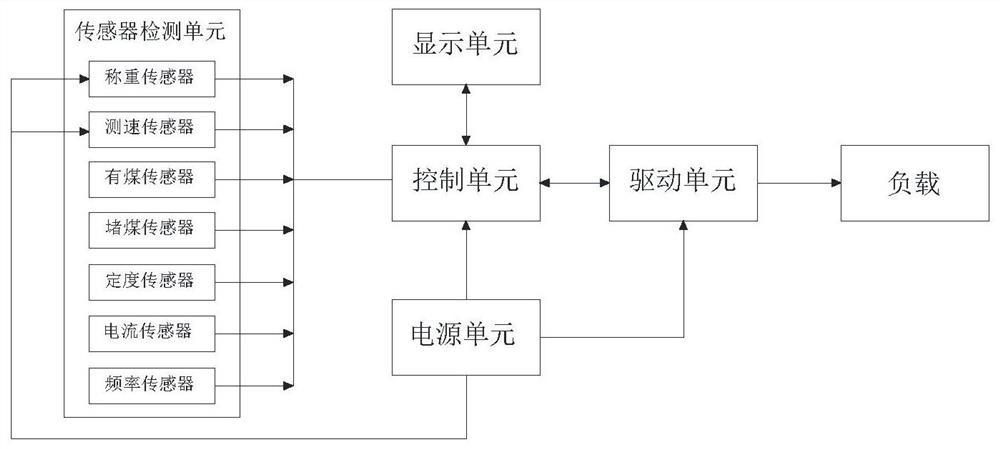

[0043] Such as figure 1 Shown, the pulverized coal feeding control system of the thermal power plant boiler of the present invention comprises:

[0044] A power supply unit, configured to provide power supply;

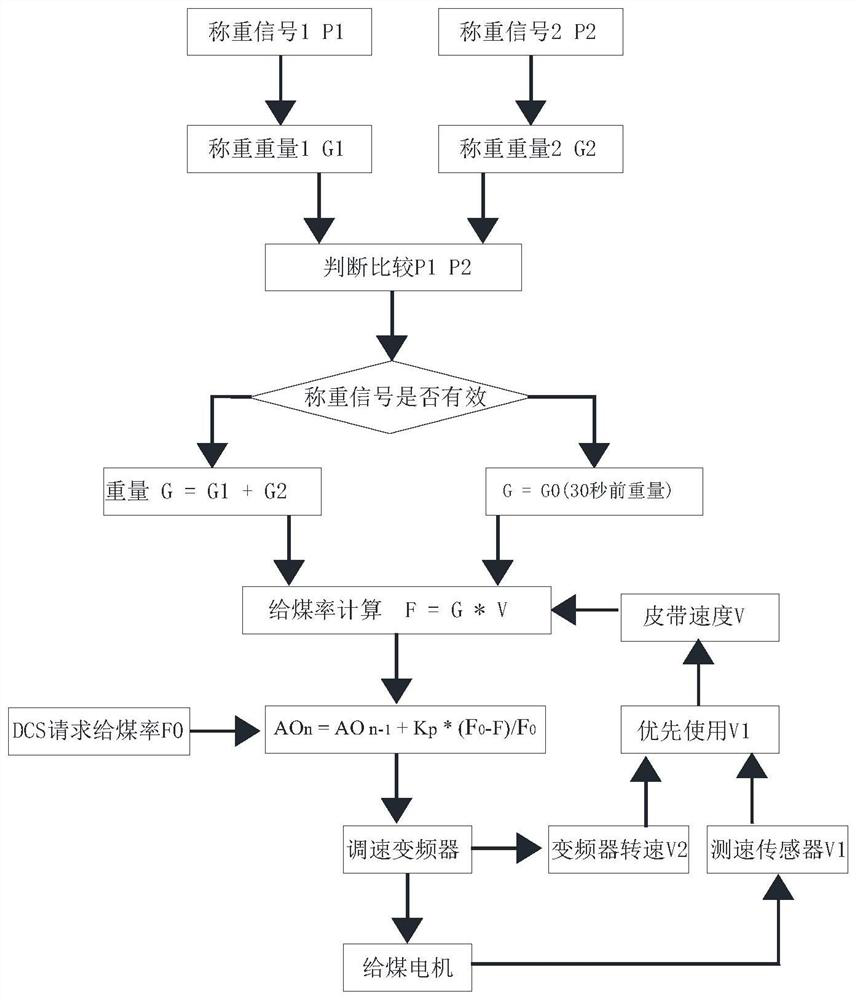

[0045] The sensor detection unit includes a load cell, a speed sensor, a constant sensor, a current sensor, and a frequency sensor; the load sensor is more than two, and the two or more load cells are jointly responsible for detecting the effective weight of the weighing object on the belt and transmitting to the control unit; the speed measuring sensor is responsible for detecting the high-speed pulse sent by the coal feeding motor and outputting the speed signal of the coal feeding motor to the control unit; the scale sensor is responsible for detecting the effective pulse number of the tare weighing span, and sending the signal Send to the control unit; the frequency sensor is responsible for detecting the operating frequency of the inverter driving the load and ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com