Line feeding system and method for electronic ignition parts

A kind of pyrotechnics and electronic technology, applied in fuzes, weapon accessories, electromagnetic radiation induction, etc., can solve the problems of poor flexibility of use, waste of labor hours, and long circulation cycle, so as to achieve good flexibility of use, improve production efficiency, and improve circulation cycle short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] This embodiment provides an online system and method for electronic igniters, which has the advantages of fewer procedures, short circulation cycle, good use flexibility, high production efficiency, and process redundancy, and can realize standardized processing of electronic igniters, unmanned Intelligent management and intelligent transmission are conducive to matching the production requirements of unmanned and intelligent assembly of industrial electronic detonators.

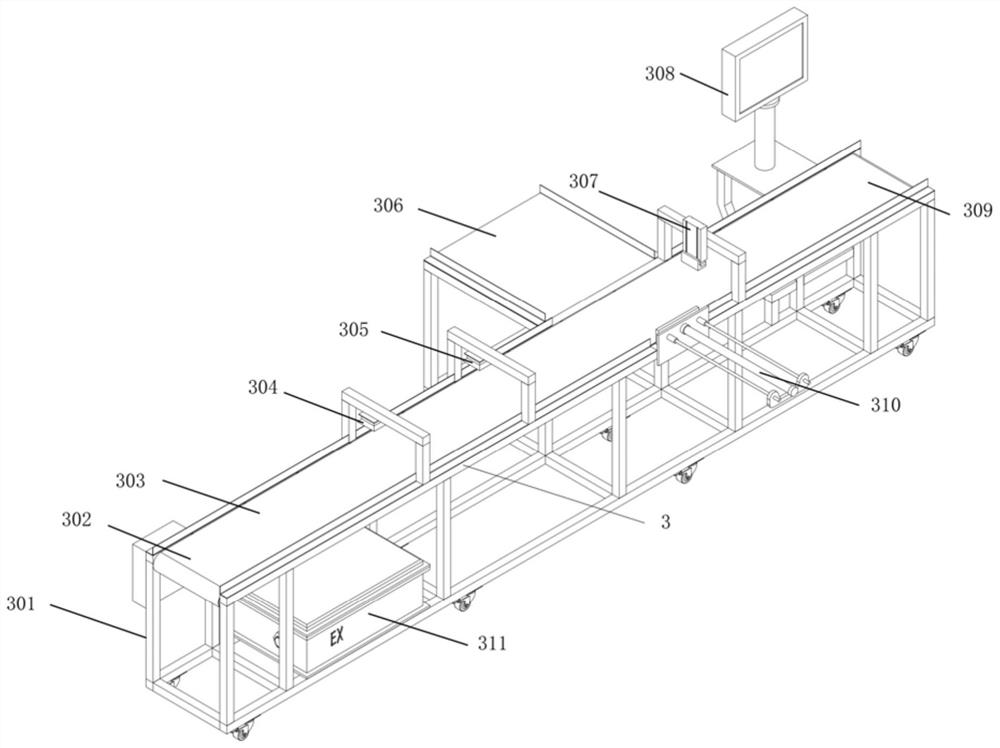

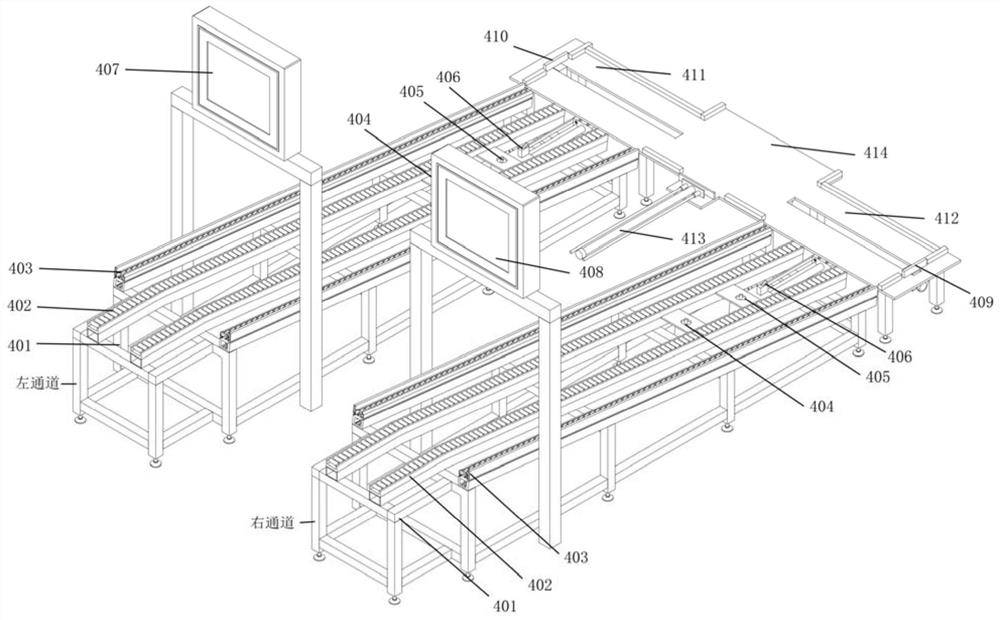

[0057] Such as Figure 1-2 As shown, the on-line system includes: a loading tray information collector 3 and a feeding channel 4; wherein, the loading tray information collecting machine 3 includes: a transfer frame 301, a loading tray entry end 302, a conveyor belt 303 (including a driving structure), and an RFID tag Initial reader 304, RFID tag inspection reader 305, unqualified disk receiving station 306, stopper 307, control computer 308, loading disk output terminal 309, unqualified disk pushing ...

Embodiment 2

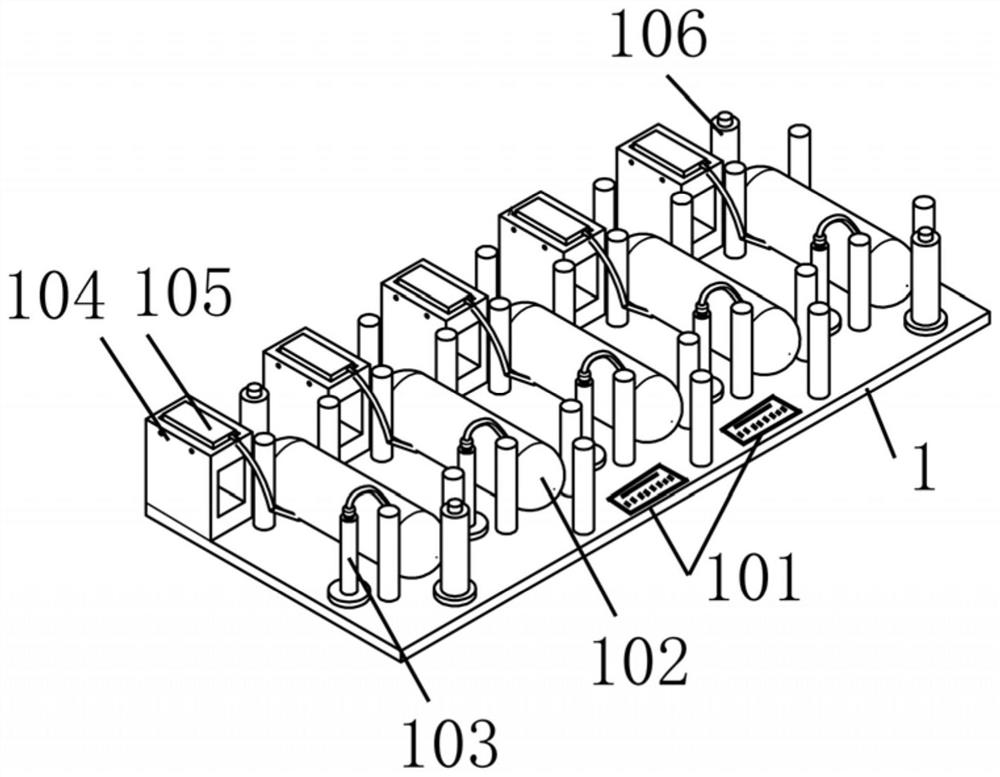

[0080] Such as image 3 As shown, on the basis of Embodiment 1, the carrier tray in the loading tray 1 also includes: a leg handle 102, an electronic fire starter protection seat 103, a junction box fixing seat 104, a junction box 105 and a fixed support column 106, which For specific settings, refer to the settings corresponding to a multi-ignition vehicle tooling (CN201920186312.4).

Embodiment 3

[0082] Such as Figure 4 As shown, on the basis of Embodiment 1 or Embodiment 2, the transfer device 2 adopts a transfer cart, including: a push handle 201, a fixed table 202, a blocking edge 203, a fixed hole 204 and a rolling wheel 205; the rolling wheel 205 is installed on The bottom of the fixed table 202 is used to drive the fixed table 202 to roll; the top of the fixed table 202 is provided with a blocking edge 203 along the circumference, which is used to block and limit the lower end of the loading tray 1 placed thereon, preventing the loading tray 1 from being fixed. Slide down on the table top 202; the blocking edge 203 is provided with a fixing hole 204, in which a fixing rope can be installed, thereby fixing the loading trays 1 stacked on the fixed table top 202, preventing multiple loading trays 1 from being easily scattered when stacked;

[0083] A push handle 201 is also fixed on the fixed table 202 for pushing or pulling the fixed table 202 or the fixed table 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com