Full-nano porous MOF/HOF composite film, preparation method and application thereof in gas separation

A nanoporous, gas separation technology, applied in semi-permeable membrane separation, separation method, dispersed particle separation, etc., can solve problems such as aging, affecting the stability of mixed matrix membrane, and easy plasticization of polymer matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

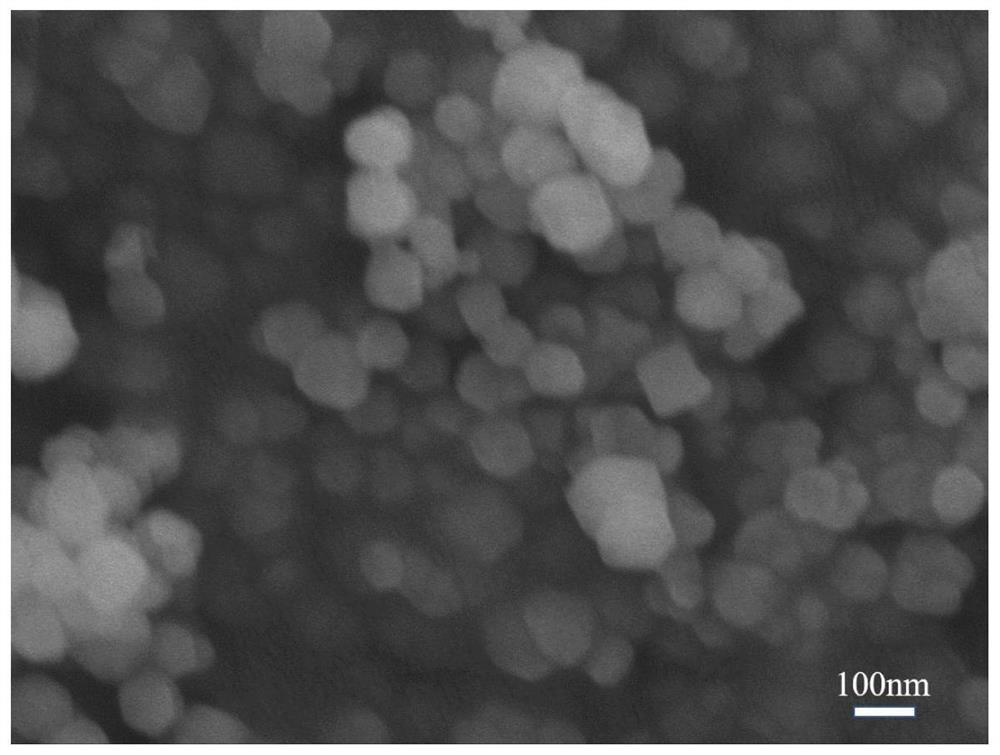

[0023] (1) Preparation of ZIF-8: Weigh 1.17g zinc nitrate (Zn(NO 3 ) 2 ) and 22.7g of 2-methylimidazole (2-HmIm) in two beakers, ultrasonically dissolved and configured as an aqueous solution. The dissolved Zn(NO 3 ) 2 The solution was quickly mixed with the 2-HmIm solution, stirred magnetically at room temperature for 5 minutes, centrifuged (6500 rpm, 30 min) to collect the product, washed with deionized water, and finally dried at 60° C. for 10 hours to obtain dry activated ZIF-8 particles.

[0024] (2) Preparation of HOF precursor NBP-DAT: Add 8.16g tris(4-bromophenyl)amine, 10.43g 4-cyanophenylboronic acid and 284.61g anhydrous N,N-dimethyl to a three-necked reaction flask Formamide (DMF), nitrogen gas after sealing to exhaust the air. After 30 minutes, add 48mL, 0.275g·mL -1 K 2 CO 3 aqueous solution and 48mL deionized water, and continue to pass nitrogen protection. After 30 minutes, 1.56 g of tetrakis(triphenylphosphine) palladium was added, and finally heated to ...

Embodiment 2

[0031] (1) ZIF-8 particles are prepared in step 1 of Example 1;

[0032] (2) prepare NBP-DAT precursor according to embodiment 1 step 2;

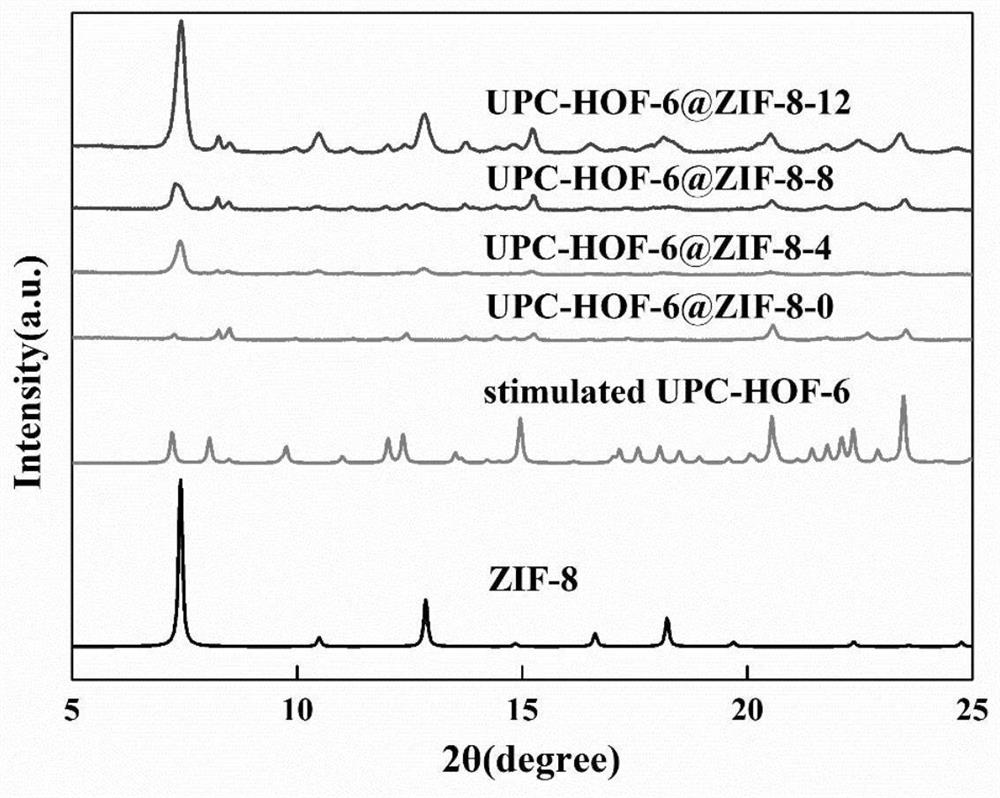

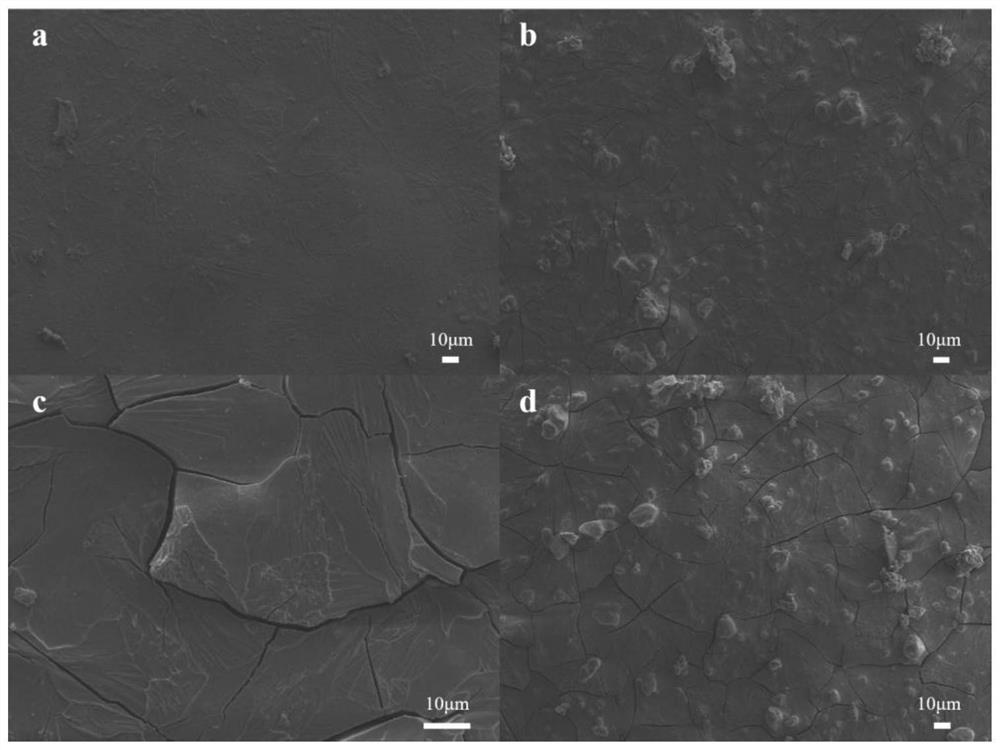

[0033] (3) Preparation of MOF / HOF composite membrane: Weigh 9.6 mg of activated ZIF-8 particles into a 10 mL glass bottle, pipette 1 mL of anhydrous dimethyl sulfoxide (DMSO) into the glass bottle, and sonicate for 30 minutes , so that the ZIF-8 particles were evenly dispersed in the DMSO solution, and then accurately weighed 120 mg of HOF precursor NBP-DAT and dissolved in the above DMSO solution, and dissolved completely at 150°C as a composite membrane casting solution. Preheat the porous α-alumina substrate at 80°C for 30 minutes, pipette 100 μL of composite membrane casting solution and evenly drop-coat it on the preheated substrate, evaporate the solvent at 80°C, and obtain a homogeneous MOF / HOF after 2 hours The composite film is denoted as UPC-HOF-6 / ZIF-8-8, and the film thickness is 7.88 μm.

[0034] (4) Membrane characterization...

Embodiment 3

[0039] (1) ZIF-8 particles are prepared in step 1 of Example 1;

[0040] (2) prepare NBP-DAT precursor according to embodiment 1 step 2;

[0041] (3) Preparation of MOF / HOF composite membrane: Weigh 14.4 mg of activated ZIF-8 particles into a 10 mL glass bottle, pipette 1 mL of anhydrous dimethyl sulfoxide (DMSO) into the glass bottle, and sonicate for 30 minutes , so that the ZIF-8 particles were evenly dispersed in the DMSO solution, and then accurately weighed 120 mg of HOF precursor NBP-DAT and dissolved in the above DMSO solution, and dissolved completely at 150°C as a composite membrane casting solution. Preheat the porous α-alumina substrate at 80°C for 30 minutes, pipette 100 μL of composite membrane casting solution and evenly drop-coat it on the preheated substrate, evaporate the solvent at 80°C, and obtain a homogeneous MOF / HOF after 2 hours The composite film is denoted as UPC-HOF-6 / ZIF-8-12, and the film thickness is 10.77 μm.

[0042] (4) Membrane characterizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com