Method for rapidly preparing Au-TiO2 composite structure under acidic condition

A technology with acidic conditions and composite structures, applied in metal processing equipment, titanium oxide/hydroxide, nanotechnology for materials and surface science, etc., can solve the problem of easy aggregation of gold nanoparticles, poor repeatability, cumbersome experimental steps, etc. problems, to achieve broad-spectrum absorption performance, fast response, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

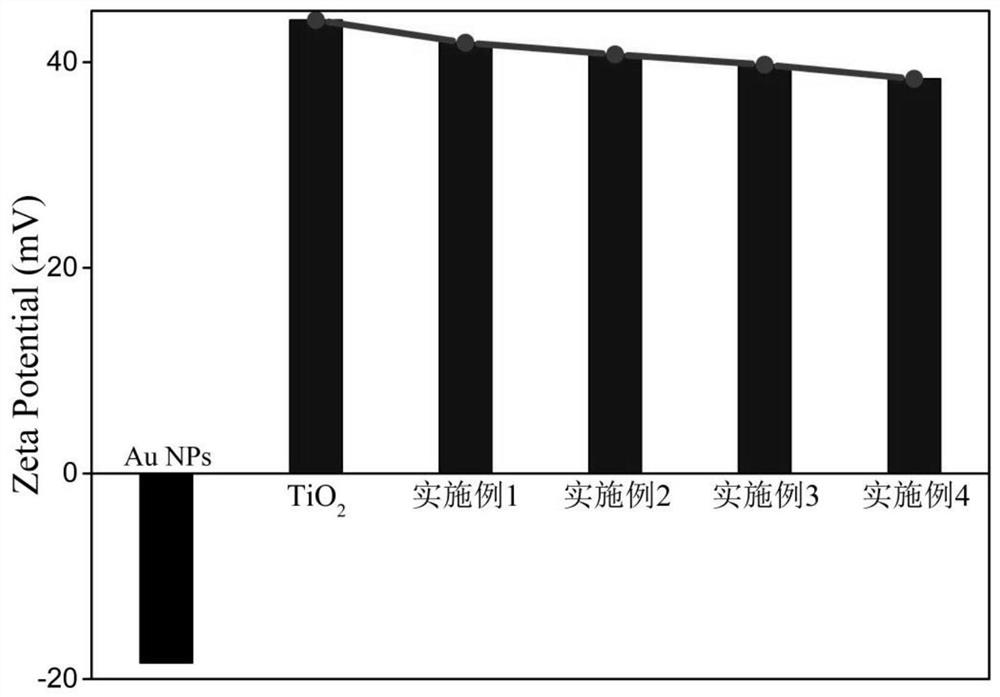

[0025] Step 1: Weigh 0.5g TiO 2 And disperse it in deionized water, then add a certain amount of hydrochloric acid to make its molar concentration 23.94mmol / L, stir evenly with magnetic force, and set aside;

[0026] Step 2: Measure 1 mL of 10 mg / mL chloroauric acid solution and add 7 mL of deionized water to dilute. Then add 10 mg of polyvinylpyrrolidone (PVP), stir evenly, quickly inject 2 mL of sodium borohydride solution, so that the concentration of polyvinylpyrrolidone is 1 mg / mL, and the concentration of sodium borohydride is 0.45 mg / mL, continue to stir for 10 min, and set aside;

[0027] Step 3: Measure 5mL of the nano-gold solution prepared in step 2, and slowly add it dropwise to the solution in step 1 at a rate of 1 drop per second, stir rapidly at a stirring speed of 2600r / min for 10min, and centrifuge the product for 3 times, Finally, dry at 60°C.

Embodiment 2

[0029] Step 1: Weigh 0.5g TiO 2 And disperse it in deionized water, then add a certain amount of hydrochloric acid to make its molar concentration 23.94mmol / L, stir evenly with magnetic force, and set aside;

[0030] Step 2: Measure 1 mL of 10 mg / mL chloroauric acid solution and add 7 mL of deionized water to dilute. Then add 10 mg of polyvinylpyrrolidone (PVP), stir evenly, quickly inject 2 mL of sodium borohydride solution, so that the concentration of polyvinylpyrrolidone is 1 mg / mL, and the concentration of sodium borohydride is 0.45 mg / mL, continue to stir for 10 min, and set aside;

[0031] Step 3: Measure 10mL of the nano-gold solution prepared in step 2, and slowly add it dropwise to the solution in step 1 at a rate of 1 drop per second, stir rapidly at a stirring speed of 2600r / min for 10min, and centrifuge the product for 3 times, Finally, dry at 60°C.

Embodiment 3

[0033] Step 1: Weigh 0.5g TiO 2 And disperse it in deionized water, then add a certain amount of hydrochloric acid to make its molar concentration 23.94mmol / L, stir evenly with magnetic force, and set aside;

[0034] Step 2: Measure 1 mL of 10 mg / mL chloroauric acid solution and add 7 mL of deionized water to dilute. Then add 10 mg of polyvinylpyrrolidone (PVP), stir evenly, quickly inject 2 mL of sodium borohydride solution, so that the concentration of polyvinylpyrrolidone is 1 mg / mL, and the concentration of sodium borohydride is 0.45 mg / mL, continue to stir for 10 min, and set aside;

[0035] Step 3: Measure 15mL of the nano-gold solution prepared in step 2, and slowly add it dropwise to the solution in step 1 at a rate of 1 drop per second, stir rapidly at a stirring speed of 2600r / min for 10min, and centrifuge the product for 3 times, Finally, dry at 60°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com