High-nitrate wastewater pretreatment system and method for coal-to-ethylene glycol

A coal-to-ethylene glycol and treatment method technology, which is applied in natural water treatment, water treatment parameter control, biological water/sewage treatment, etc., can solve the problems of high nitrate wastewater treatment difficulty and high treatment cost, and achieves the treatment cost. Low, low impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

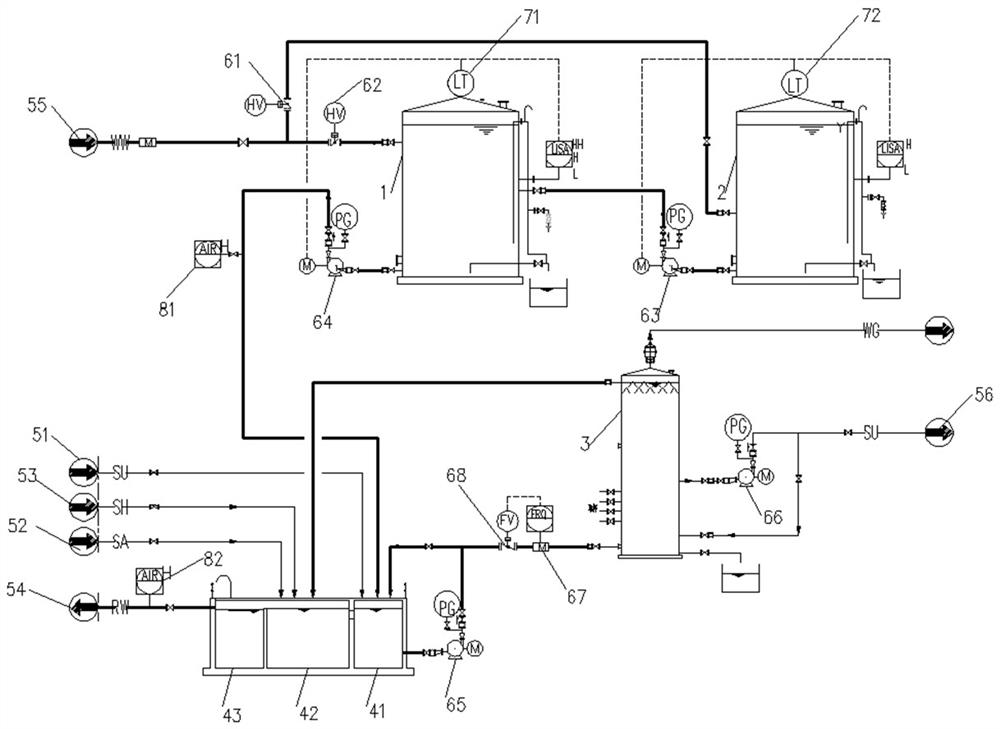

[0044] See figure 1 , a high nitrate wastewater pretreatment system for coal-to-ethylene glycol,

[0045] The pretreatment system includes a regulating tank 1, an emergency tank 2, a reactor 3 and a water distribution tank group, and the reactor 3 is an expanded granular sludge bed,

[0046] The water distribution pool group includes an inlet pool 41, an outlet pool 42, and a drainage pool 43 arranged side by side in sequence, and an overflow pipe connects the outlet pool 42 and the inlet pool 41, and a weir is provided between the outlet pool 42 and the drainage pool 43 plate;

[0047] The water inlet pool 41 is connected to the flocculent sludge inlet 51 through the pipeline, the water outlet pool 42 is connected to the sulfuric acid inlet 52 and the sodium hydroxide solution inlet 53 through the pipeline, and the drainage pool 43 is connected to the water outlet 54 through the pipeline;

[0048] The high nitrate wastewater inlet 55 is connected in parallel with two branch...

Embodiment 2

[0057] The present invention also includes a treatment method for a high-nitrate wastewater pretreatment system for coal-to-ethylene glycol, comprising the following steps:

[0058] Step (1) Inoculation

[0059] The flocculent sludge is passed into the water inlet tank 41 through the flocculent sludge inlet 51, and the flocculent sludge is passed into the reactor 3 through the inflow lift pump 65, and the flocculent sludge is inoculated in the reactor 3; the selected flocculent sludge VSS / SS of sludge is 0.65~0.75, SRT>25d;

[0060] Step (2) Homogenization

[0061] The high nitrate wastewater is introduced into the regulating tank 1 through the high nitrate wastewater inlet 55, and the temperature of the high nitrate wastewater is controlled to be 15-35°C, and the homogenization time of the high nitrate wastewater in the regulating tank 1 is 48 hours. Obtain homogeneous high nitrate wastewater;

[0062] Step (3) Reaction

[0063] Normally close the cut-off valve 61, open t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com