Preparation method of zinc oxide-based ceramic sputtering target material

A sputtering target, zinc oxide-based technology, applied in sputtering coating, metal material coating process, vacuum evaporation coating and other directions, can solve the problems of insufficient bonding strength, difficult to form, small effect, etc., and achieve particle size Reasonable range and evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

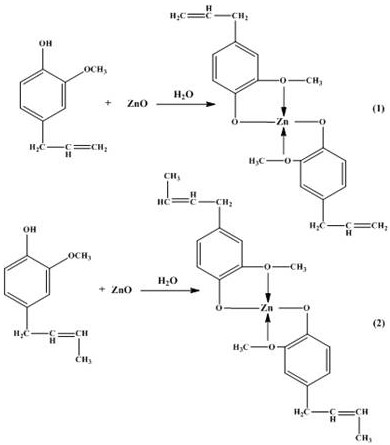

Image

Examples

Embodiment 1

[0033] The first step is to prepare zinc oxide glue: weigh the raw materials, weigh calamus oil, asarum oil, laurel oil, ylang-ylang oil, and doped zinc oxide powder for later use, wherein the calamus oil: asarum oil: laurel The volume ratio of oil: ylang-ylang oil is 2:4:6:3, the ratio of the ylang-ylang oil: doped zinc oxide powder mL:g is 1:53, and it also includes zinc stearate, olive oil and alumina , Wherein the mass ratio of the zinc stearate: olive oil: alumina is 4:2:5, and the mass ratio of the alumina: zinc oxide powder is 1:72. After the components are uniformly mixed, that is, The zinc oxide glue is obtained; the second step is to add the zinc oxide nanopowder with a mass fraction of 0.2%. The zinc oxide glue obtained in the first step is molded at 25MPa and held at 170°C for 2 minutes to obtain a molded blank; 、Raise the molded blank to the first set temperature of 600°C at a heating rate of 20°C / min and keep it for 10 minutes, and then heat it up to the sintering tem...

Embodiment 2

[0035]The first step is to prepare zinc oxide glue: weigh the raw materials, weigh calamus oil, asarum oil, laurel oil, ylang-ylang oil and doped zinc oxide powder for later use, wherein the calamus oil: asarum oil: laurel The volume ratio of oil: ylang-ylang oil is 1:3:4:1, the ratio of the ylang-ylang oil: doped zinc oxide powder mL:g is 1:47, and it also includes zinc stearate, olive oil and alumina , Wherein the mass ratio of the zinc stearate: olive oil: alumina is 3:1:4, and the mass ratio of the alumina: zinc oxide powder is 1:67. After the components are uniformly mixed, that is, Zinc oxide glue is obtained; the second step is to add the zinc oxide nanopowder with a mass fraction of 0.1%. The zinc oxide glue obtained in the first step is molded at 20 MPa and held at 150°C for 1 min to obtain a molded blank; 、Raise the molded blank to the first set temperature of 600℃ at a heating rate of 15℃ / min, and keep it for 5 minutes, and then heat it up to the sintering temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com