Method for preparing lithium battery electrode by using supercritical current collector and electrode

A lithium battery and supercritical technology, applied in the field of materials, can solve the problems of increased drying rate, high manufacturing cost, and reduced adhesive force, and achieve the effect of reducing the introduction of impurities, reducing cost and pollution, and enhancing adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

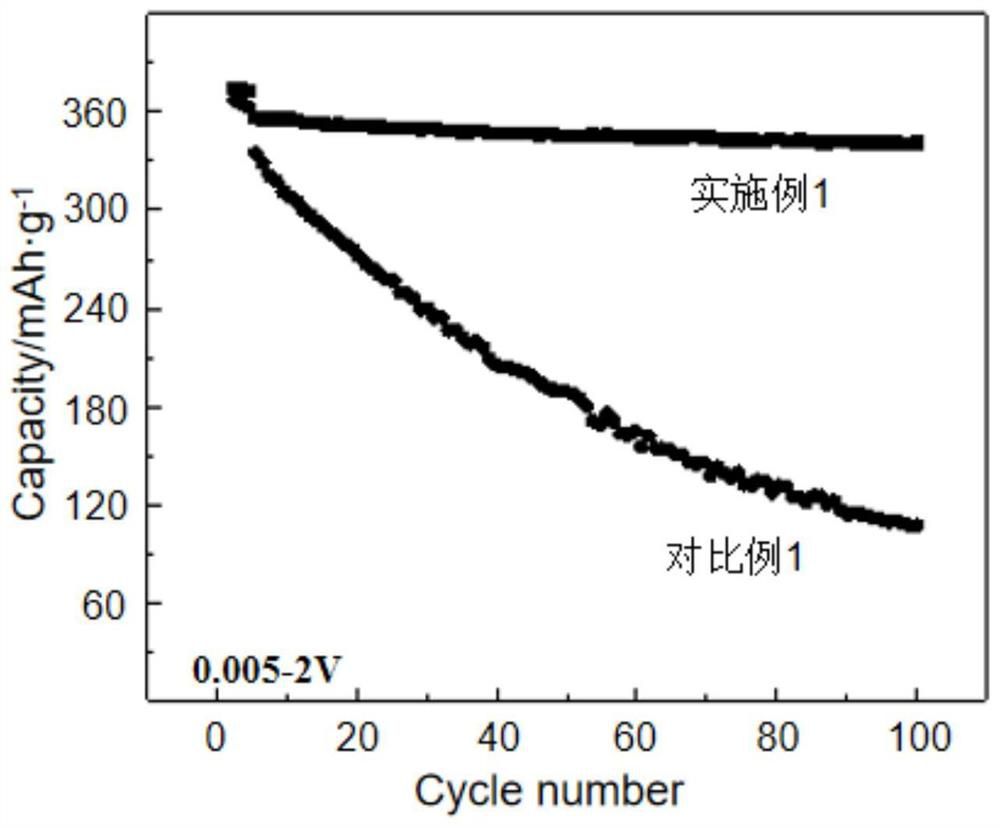

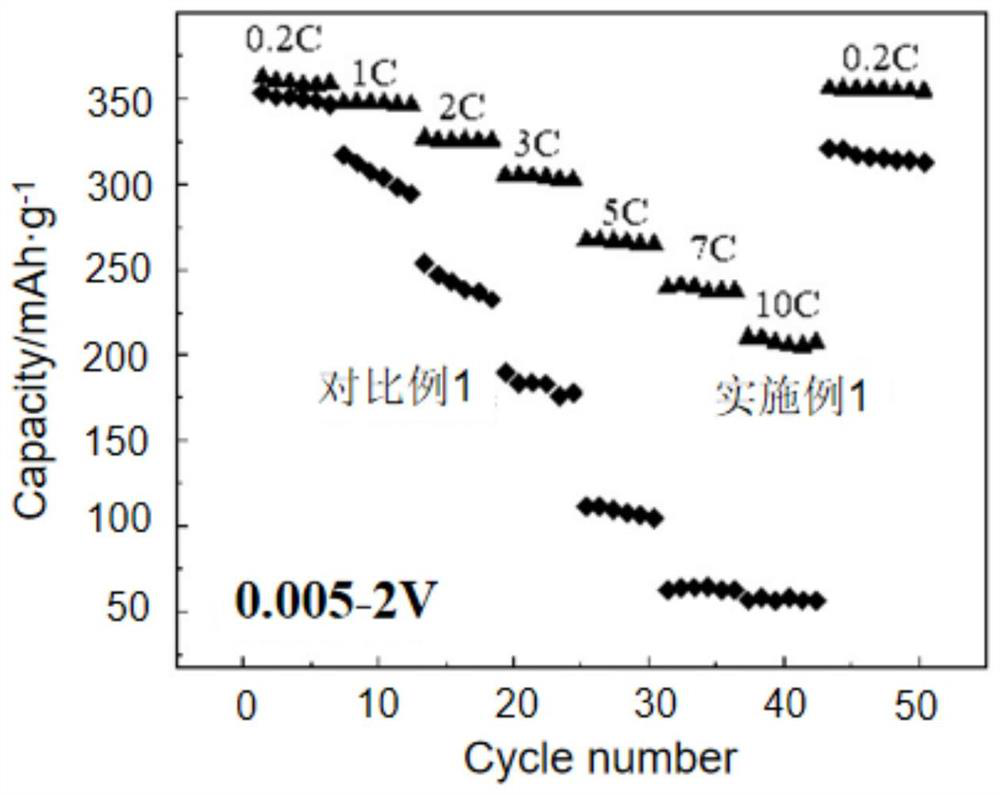

[0049] The lithium battery electrode material obtained by the preparation method of the invention has good cycle stability, storage life, high temperature performance, safety performance and rate performance.

[0050] In order to better understand the technical solutions provided by the present invention, the following specific examples illustrate the specific process of preparing lithium battery electrodes by applying the methods provided in the above embodiments of the present invention, as well as the methods and battery characteristics of applying them to lithium batteries .

Embodiment 1

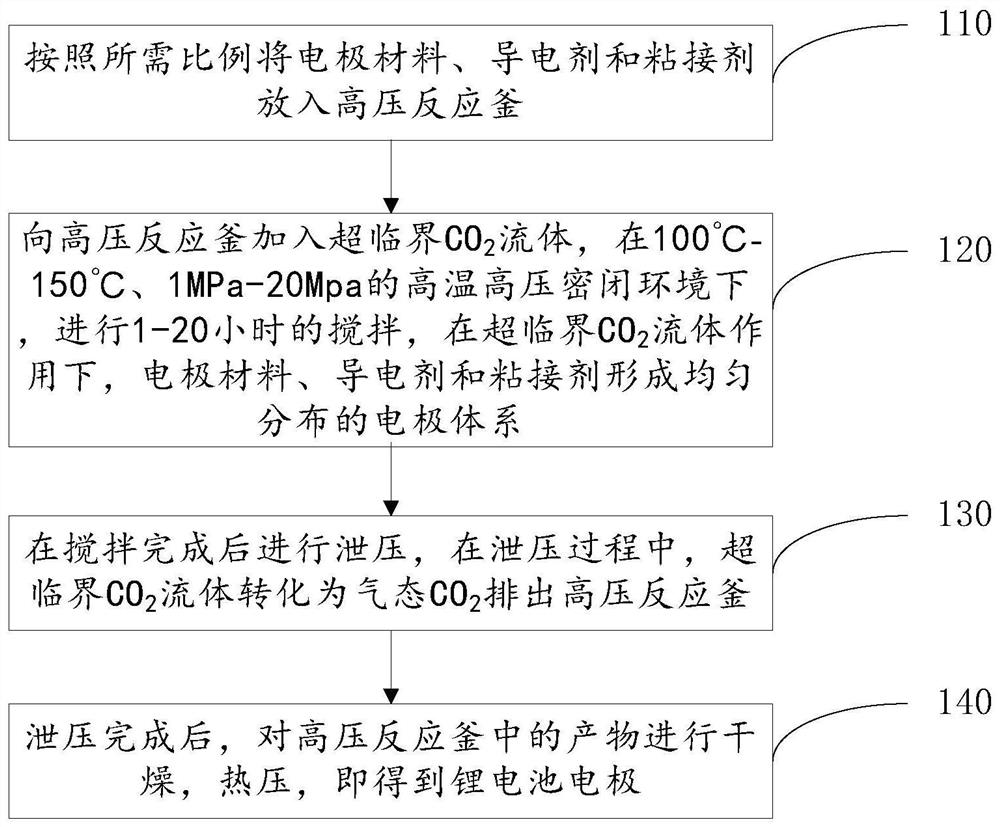

[0052] This embodiment provides a method for preparing a lithium battery electrode using a supercritical current collector, comprising the following steps:

[0053] Under the conditions of 120°C and 20MPa, put the graphite negative electrode material, conductive carbon black, styrene-butadiene rubber and sodium carboxymethyl cellulose (CMC) into the autoclave according to the mass ratio of 90:5:2.5:2.5, and pour into the autoclave Add high-pressure supercritical CO 2 For fluid, the closed system of the high-pressure reactor was stirred continuously at 120°C and 20MPa at a speed of 1500rpm for 20 hours, and then the pressure was released. After drying, the obtained material was hot-pressed to obtain a negative electrode sheet.

Embodiment 2

[0065] This embodiment provides a method for preparing a lithium battery electrode using a supercritical current collector, comprising the following steps:

[0066] Under the conditions of 115°C and 15MPa, put the silicon-oxygen negative electrode material, conductive carbon black, styrene-butadiene rubber and CMC into the autoclave according to the mass ratio of 88:6:3:3, and add high-pressure supercritical CO to the autoclave. 2 For the fluid, the closed system of the high-pressure reactor was stirred continuously at a speed of 1200 rpm for 10 hours at 115°C and 15 MPa, and then the pressure was released. After drying, hot pressing was performed to obtain a negative electrode sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com