High shear solid phase synthesis

一种固相合成、聚合树脂的技术,应用在肽的制备方法、化学/物理/物理化学过程、有机化学等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0195] Example 1 - Resin Bead Stability Check

[0196] equipment and configuration

[0197] To characterize and optimize the method for industrial applications, the influence of device operation and geometry (i.e., the fluid dynamics of the system) on the method was estimated. The study evaluated the stability of polymeric resin beads after mixing and compared three mixing methods:

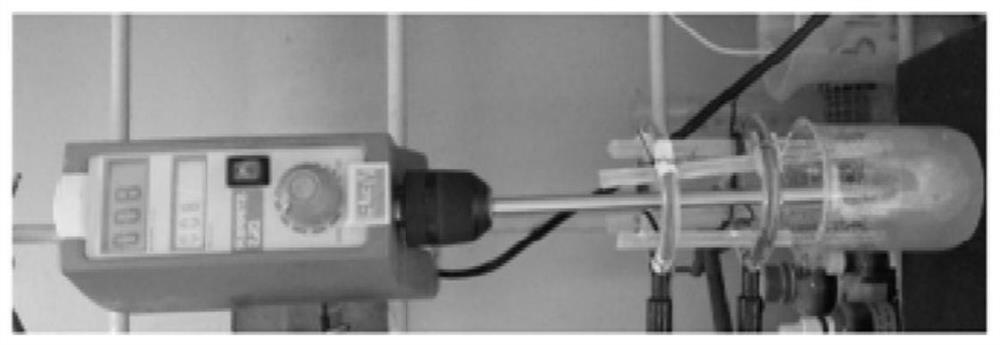

[0198] (i) A hybrid method comprising an HS-SPS device consistent with some embodiments of the invention ( Figure 1A and 1B ).

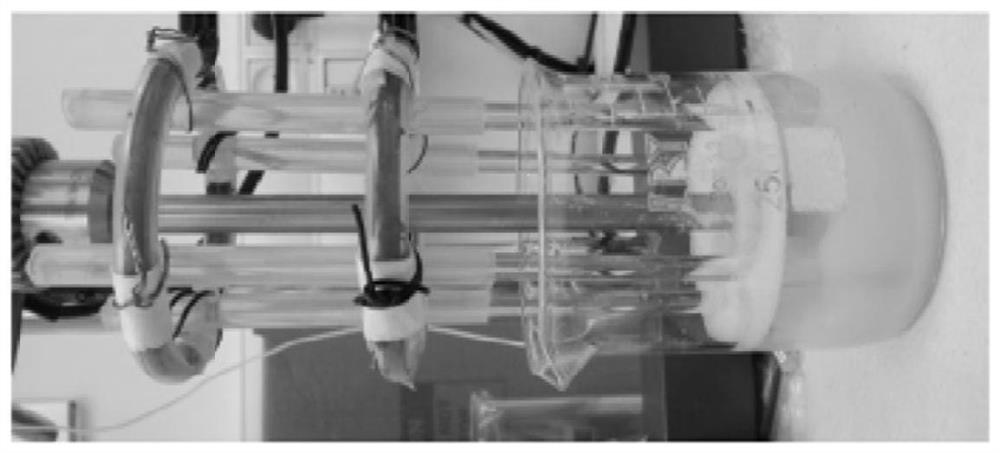

[0199] (ii) Mixing method using a magnetic stirrer ( figure 2 ).

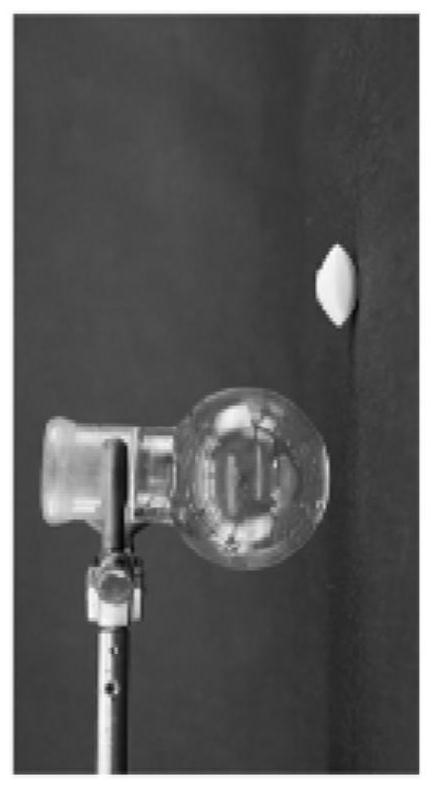

[0200] (iii) Mixing method using a homogenizer ( image 3 ).

[0201] The HS-SPS apparatus consisted of a reactor consisting of a 250 mL beaker (6.8 cm in diameter and 10 cm in height) equipped with a mechanical stirrer and high shear stress equipment. The reactor also included 4 baffles, each with a thickness of 0.6 cm. Two mechanical stirrers were checked:

[0202] 1. Stirrer consisting o...

Embodiment 2

[0237] Example 2 - Resin Bead Swelling Check

[0238] Swelling of dry resin beads is performed at the initial stage of the solid-phase peptide synthesis method. NMP, DMF (dimethylformamide), and DCM (dichloromethane) are considered to be good swelling solvents for polystyrene-divinylphenyl resins and are commonly used in the SPSS process, although TentaGel resins are known to be Swell to a certain extent. Swelling is a direct function of the interaction and compatibility of the solvent properties with the resin and the operating conditions in the equipment. In commonly used shaker reaction vessels, the swelling step is usually completed within one to two hours.

[0239] The swelling kinetics of the polymeric beads were tested in an agitated tank by adding the beads to the solvent in the tank and stirring at 600-700 rpm for two hours. Very similar to the stability evaluation experiments, the swelling kinetics of TentaGel beads in water were evaluated using HS-SPS apparatus...

Embodiment 3

[0248] Example 3 - Coupling and Racemization Check

[0249] As mentioned above, peptide synthesis is usually performed in solid phase by using a shaker apparatus. To demonstrate the feasibility of the high-shear solid-phase peptide synthesis (HS-SPPS) approach, the two approaches were compared using tripeptide synthesis as a model. The transformation of choice is the coupling reaction of an amino-protected amino acid with a dipeptide attached to the resin to form a tripeptide-containing resin. Specifically, the model peptide to be synthesized is Fmoc-L-His-Phe-Gly-NH 2 . Therefore, the model reaction includes a combination of glycine (Gly) and phenylalanine (Phe) units (H 2 The free amine residue of the resin of N-Phe-Gly-resin and trityl (trityl-Ph 3 C) Histidine unit protected and protected by Fmoc (fluoroalkenylmethoxycarbonyl) on its primary amine (Fmoc-His(Trt)OH; N α -Fmoc-N (im) - Trityl-L-histidine; CAS NO 109425-51-6) carboxyl residue coupling. It should be n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com