Hemispherical harmonic oscillator flow channel constraint-shear rheological polishing method and device

A hemispherical resonator and resonator technology, used in surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve problems such as low efficiency, poor surface quality, and low precision, and achieve high polishing efficiency, flow Road structure optimization, the effect of small normal force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

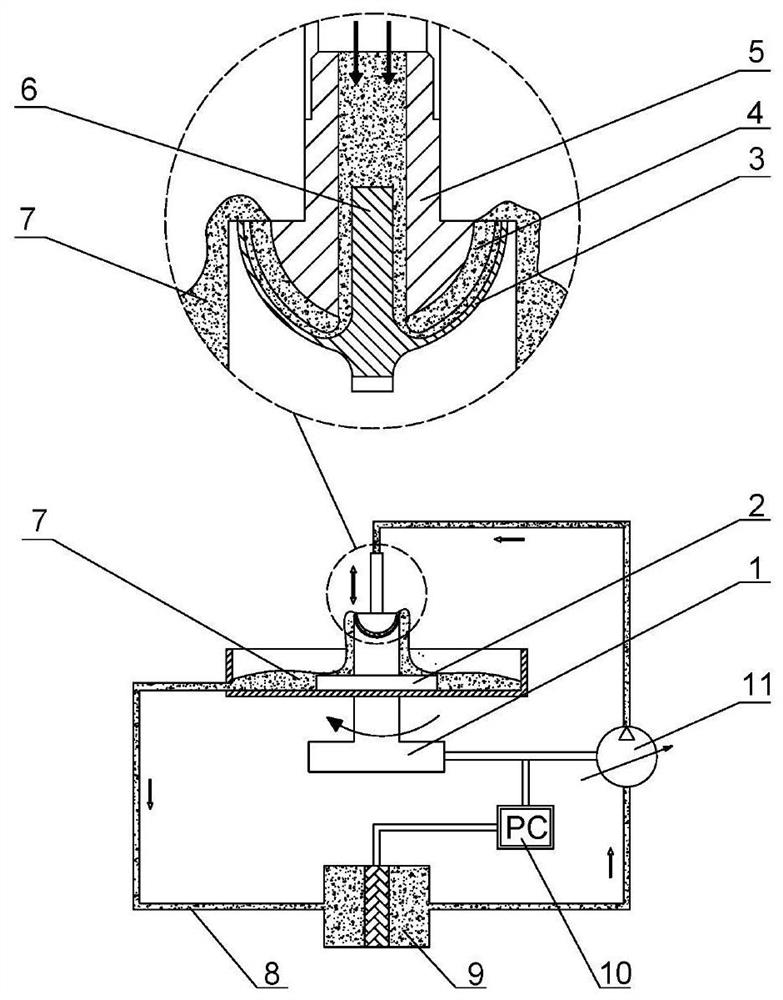

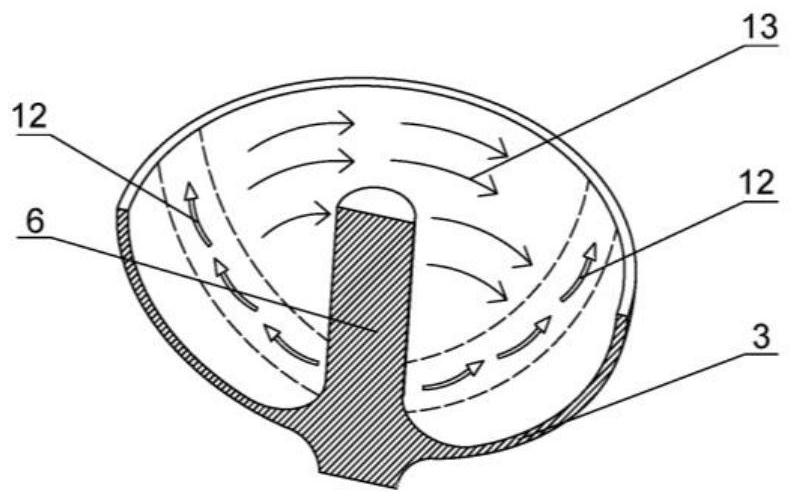

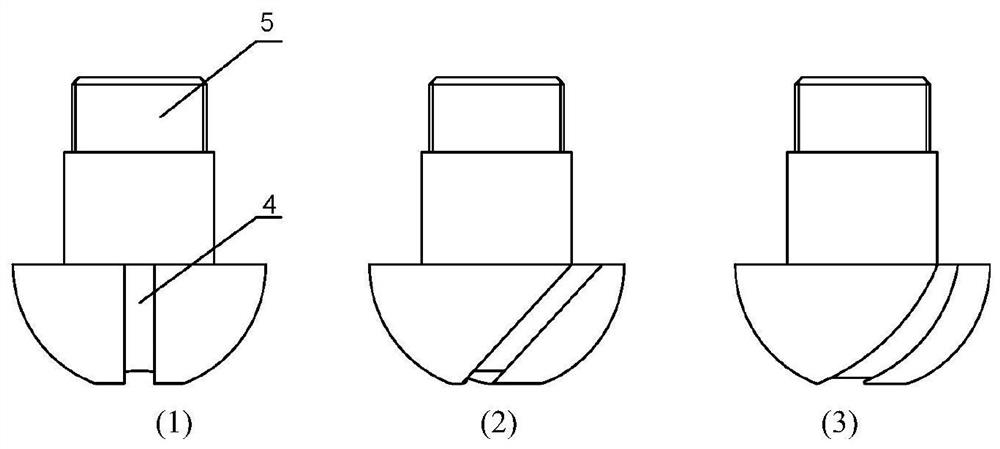

[0035] refer to Figure 1 to Figure 6 , a hemispherical harmonic oscillator channel confinement-shear rheological polishing method, comprising the following steps:

[0036] (1) Prepare non-Newtonian fluid polishing fluid 7 with shear rheological effect. The non-Newtonian fluid base fluid is a non-Newtonian fluid composed of polyhydroxy polymer and water. The abrasive is selected from 3000# diamond and aluminum oxide mixed abrasives, and the concentrations are respectively 5% and 12%, the additives are selected from guar gum and potassium sorbate, and the prepared polishing solution is added to the polishing solution station 9;

[0037] (2) The hemispherical resonator 3 is glued on the hemispherical resonator 3 with the circular plane on the thin-walled edge of the hemispherical resonator as the positioning surface. Figure 6On the fixture 2 shown, it is required that the flange transfer surface of the fixture is perpendicular to the axis of the fixture. The fixture 2 is trans...

Embodiment 2

[0048] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the abrasive grains in the shear rheological polishing fluid 7 described in step (1) are aluminum oxide, diamond, silicon carbide, silicon oxide, cerium oxide, boron carbide, One or a mixture of at least two of zirconia, the additives include one or a mixture of at least two of dispersants, surfactants, pH regulators, and chemical active agents. Other steps and parameters are the same as in Example 1.

Embodiment 3

[0049] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the connection mode between the hemispherical resonator 3 and the fixture 2 in step (2) is vacuum adsorption or self-centering chuck clamping. Other steps and parameter are identical with embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com