Folding mechanism suitable for folding morphing wing

A folding mechanism and variant wing technology, applied in the directions of wings, wing adjustment, aircraft parts, etc., can solve the problems of poor load-bearing capacity, serious wing structure coupling, unfavorable mechanism maintenance and replacement, etc., to save space, Simple connection, reduced weight and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

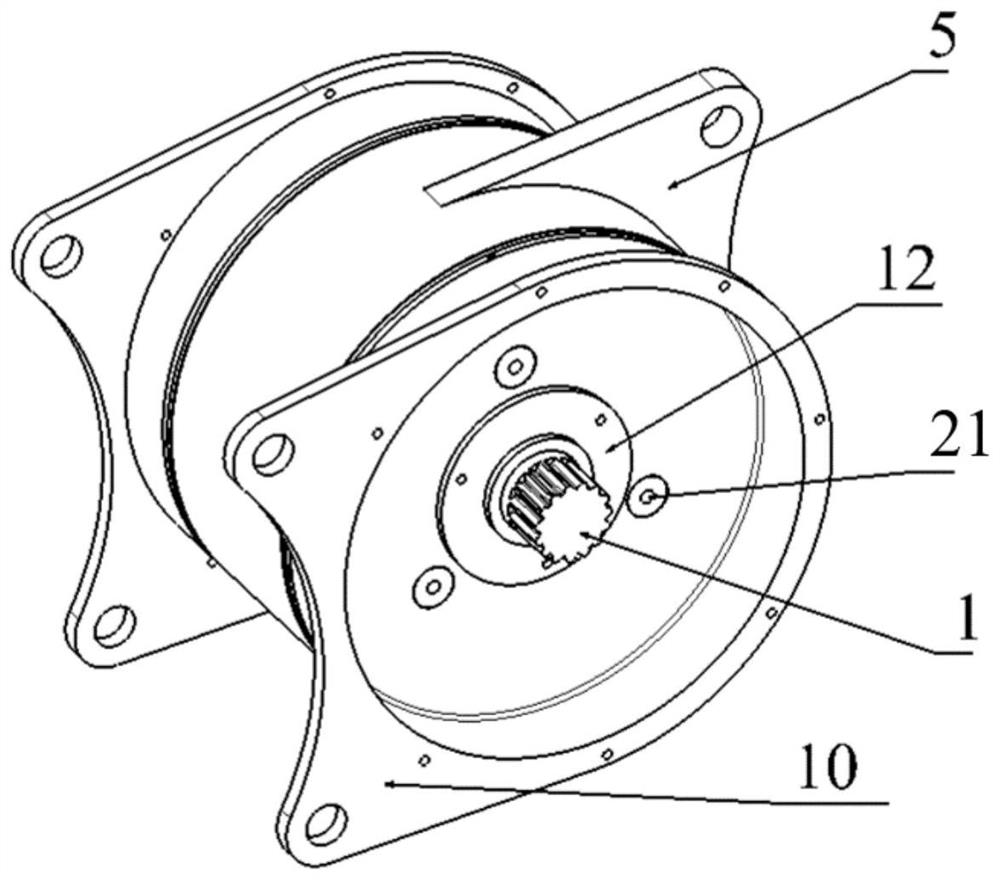

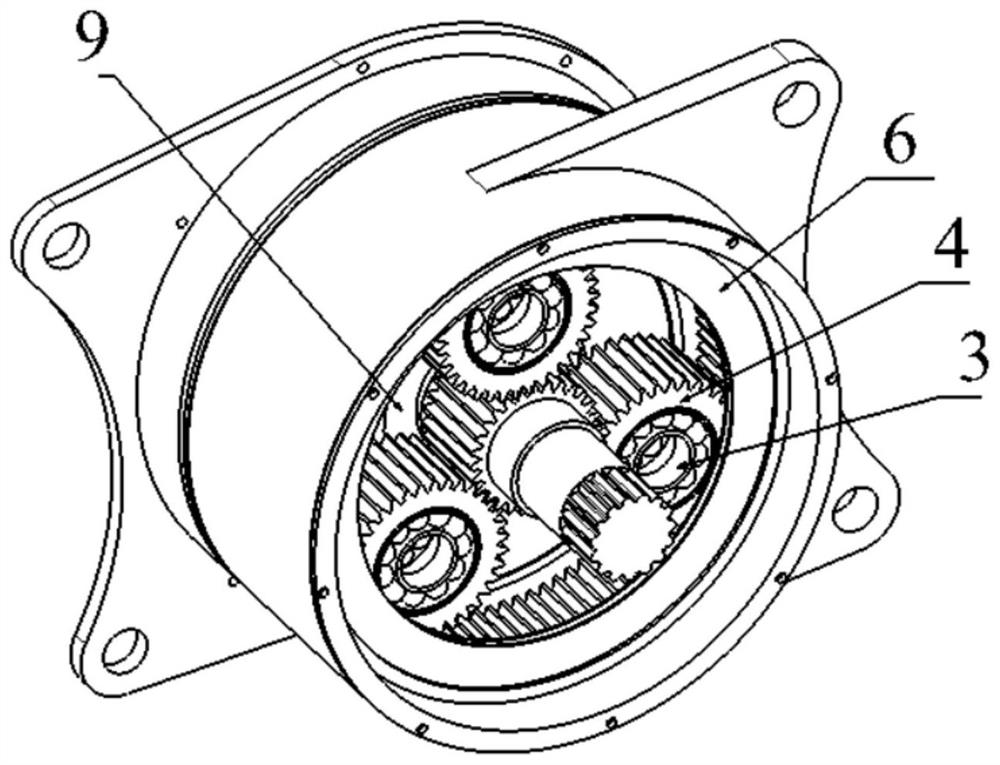

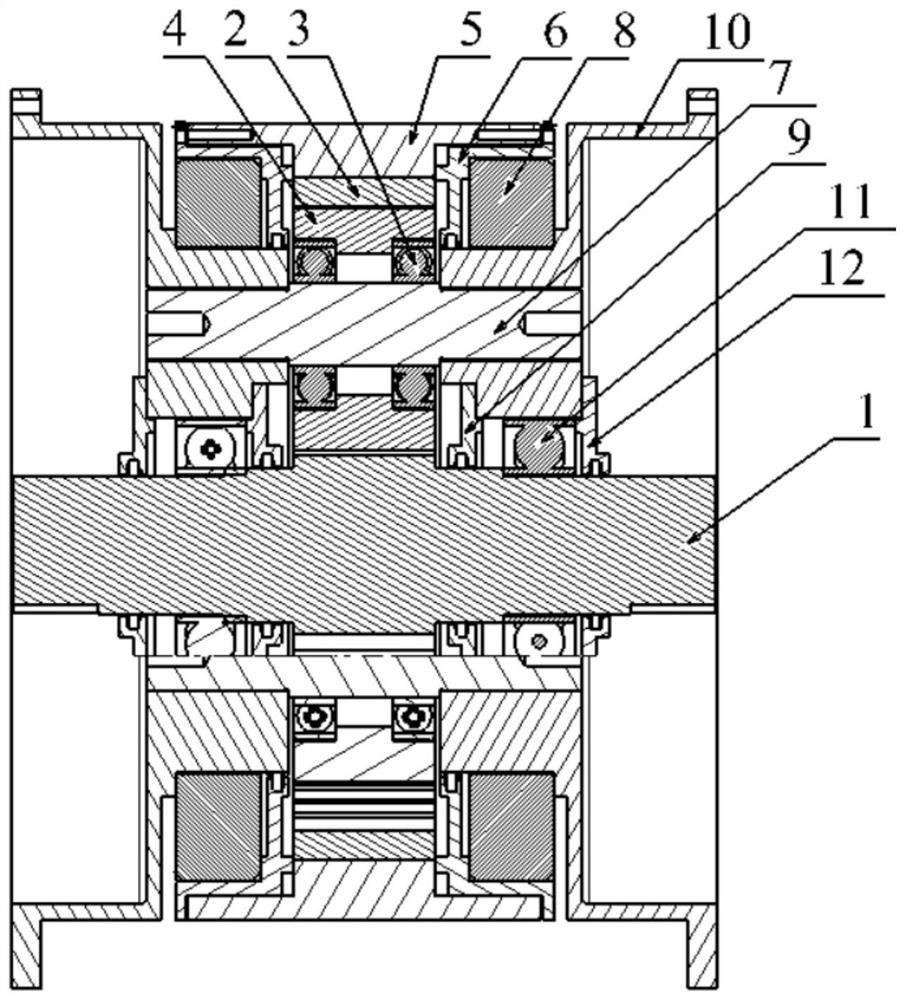

[0055] Example: Folding variant wing model sample design for a certain project

[0056] In this example, the arrangement of the folding mechanisms adopts a mixed arrangement, and every three folding mechanisms form a folding mechanism group, and the two folding mechanism groups are connected through the outer sleeve (13) and the transmission shaft (16). The motor (15) arranged in the inner structure of the wing section transmits the output torque to the folding mechanism through the bevel gear commutator (14), so as to realize the rotation action of the folding mechanism group. The outer planet carrier (10) of the outermost folding mechanism of the folding mechanism group is bolted to the housing of the bevel gear commutator (14) through mounting holes arranged circumferentially at the bottom of the planet carrier (10).

[0057] Figure 7 Show the physical model of the folding mechanism according to an embodiment of the present invention and the photograph of its static test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com