Peanut shell biochar composite hydrogel and application thereof in tobacco planting

A technology of composite hydrogel and peanut shell, which can be used in application, tobacco cultivation, planting substrate, etc., can solve problems such as unknown effect and human health risk, and achieve timely closure of stomata, reduction of toxic effects, and improvement of tobacco leaf surface. type effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

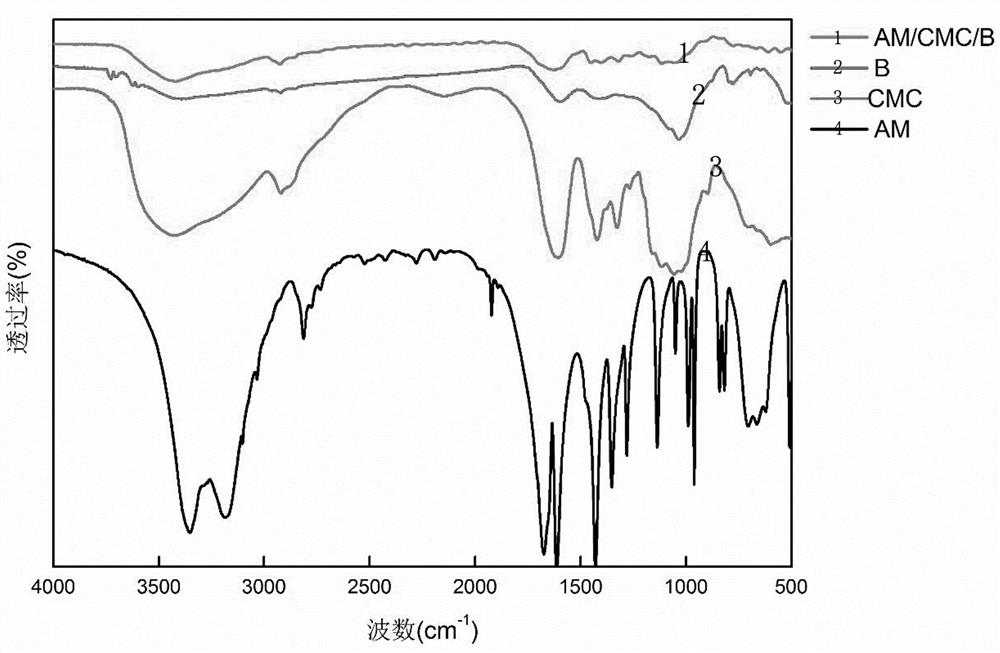

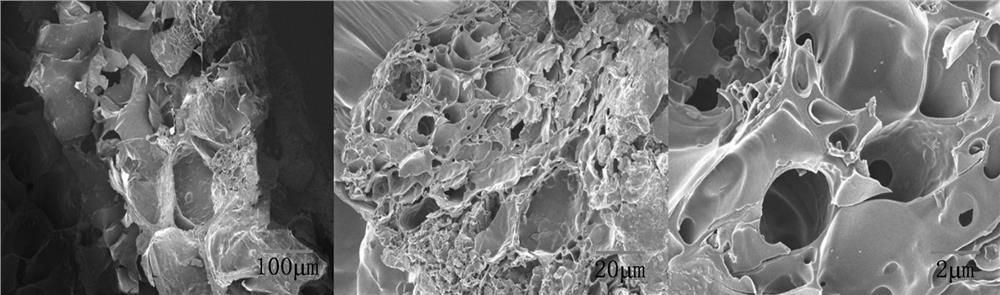

[0042] Example 1: The peanut shell biochar composite hydrogel provided in this example, the composite hydrogel includes peanut shell biochar (B), acrylamide (AM), carboxymethyl cellulose (CMC), ammonium persulfate (APS) and N,N'-methylenebisacrylamide (MBA), where peanut shell biochar: carboxymethyl cellulose: acrylamide = 4:1:8, where the mass of ammonium persulfate is acrylamide and 1% of the mass sum of carboxymethyl cellulose, and 0.5% of the mass sum of acrylamide and carboxymethyl cellulose in the mass of N,N'-methylenebisacrylamide.

[0043] Preparation:

[0044] The first step is to cut the washed and naturally air-dried peanut shells into small pieces of about 2cm and crush them through a 2mm sieve with a grinder, then put the crushed peanut shells in a muffle furnace, and pyrolyze them at 450°C for 3 hours to obtain peanut shell organisms charcoal, after the reaction, close the muffle furnace and wait for the pyrolysis gas to cool down to room temperature, take out ...

Embodiment 2

[0047]Example 2: The peanut shell biochar composite hydrogel provided in this example, the composite hydrogel includes peanut shell biochar (B), acrylamide (AM), carboxymethyl cellulose (CMC), ammonium persulfate (APS) and N,N'-methylenebisacrylamide (MBA), where peanut shell biochar: carboxymethyl cellulose: acrylamide = 3:1:6, where the mass of ammonium persulfate is acrylamide and The mass sum of carboxymethyl cellulose is 0.5%, and the mass of N,N'-methylenebisacrylamide is 0.3% of the mass sum of acrylamide and carboxymethyl cellulose.

[0048] Preparation:

[0049] The first step is to cut the washed and naturally air-dried peanut shells into small pieces of about 2cm and crush them through a 2mm sieve with a pulverizer, then put the crushed peanut shells in a muffle furnace, and pyrolyze them at 420°C for 4 hours to obtain peanut shell organisms charcoal, after the reaction, close the muffle furnace and wait for the pyrolysis gas to cool down to room temperature, take ...

Embodiment 3

[0052] Example 3: The peanut shell biochar composite hydrogel provided in this example, the composite hydrogel includes peanut shell biochar (B), acrylamide (AM), carboxymethyl cellulose (CMC), ammonium persulfate (APS) and N,N'-methylenebisacrylamide (MBA), where peanut shell biochar: carboxymethyl cellulose: acrylamide = 5:1:10, where the mass of ammonium persulfate is acrylamide and The mass sum of carboxymethyl cellulose is 1.5%, and the mass of N,N'-methylenebisacrylamide is 0.8% of the mass sum of acrylamide and carboxymethyl cellulose.

[0053] Preparation:

[0054] The first step is to cut the washed and naturally air-dried peanut shells into small pieces of about 2cm and crush them through a 2mm sieve with a grinder, then place the crushed peanut shells in a muffle furnace, and pyrolyze them at 480°C for 2 hours to obtain peanut shell organisms charcoal, after the reaction, close the muffle furnace and wait for the pyrolysis gas to cool down to room temperature, take...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

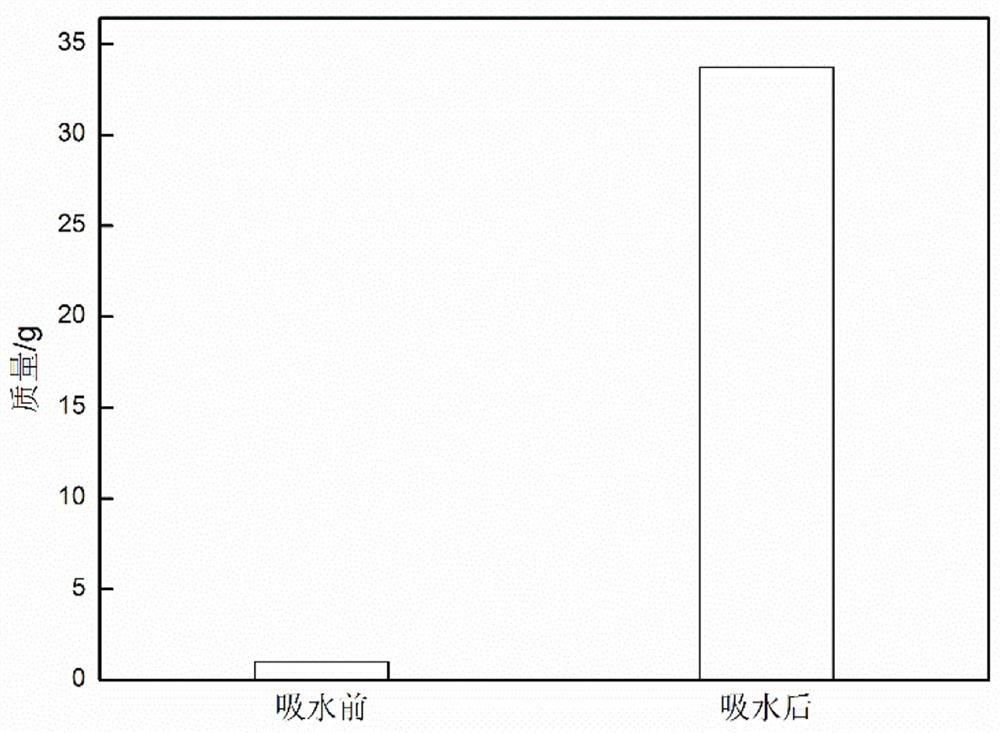

| Degree of swelling | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap