A kind of porous organic framework material, preparation method and application in selective separation of perrhenate

An organic framework, perrhenate technology, applied in the direction of organic anion exchangers, organic cation exchangers, separation methods, etc., can solve problems such as unsatisfactory selective separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

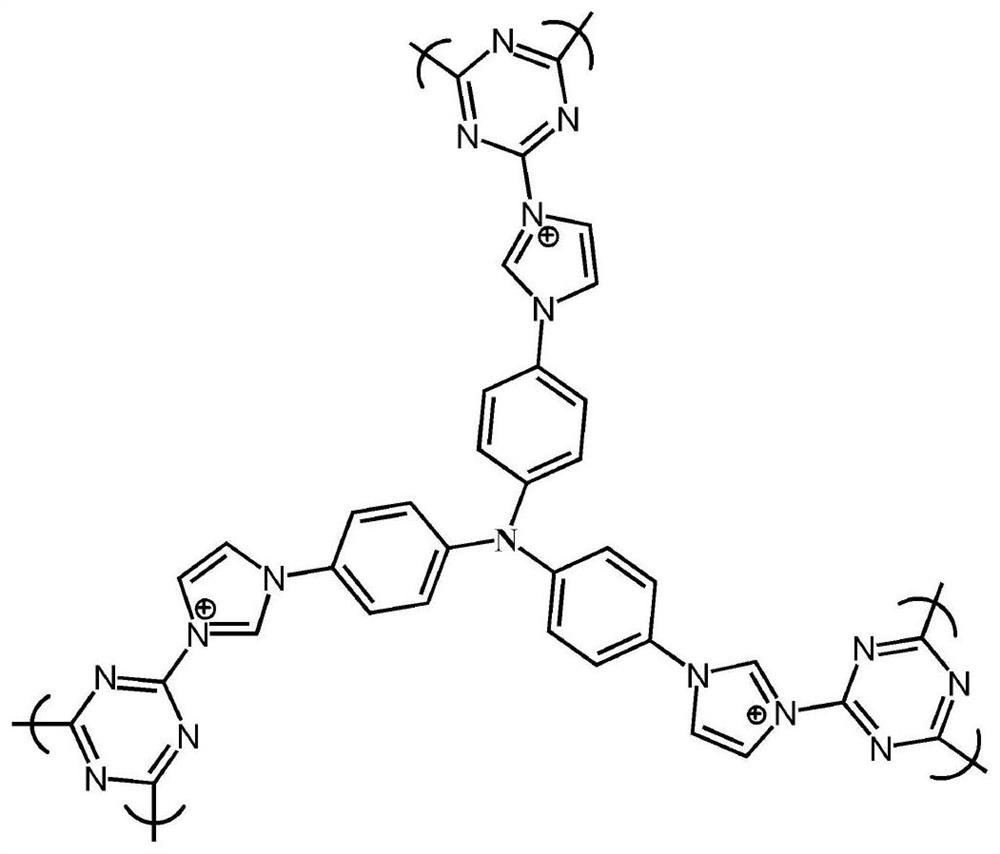

[0024] The invention provides a preparation method of a porous organic framework material, comprising the following steps:

[0025] Tris(4-imidazolylphenyl)amine, cyanuric chloride and organic solvent are mixed to carry out quaternization reaction to obtain porous organic framework material.

[0026] In the present invention, the substance amount ratio of the tris(4-imidazolylphenyl)amine and cyanuric chloride is preferably (0.6-1.2):(0.4-0.8), more preferably 1:1. In the present invention, the amount ratio of the tris(4-imidazolylphenyl)amine and cyanuric chloride is within the above-mentioned range so that a sufficient quaternization reaction can be performed.

[0027] In the present invention, the organic solvent is preferably N,N'-dimethylformamide, N,N'-dimethylacetamide or N-methylpyrrolidone. In the present invention, the amount of the organic solvent is not particularly limited, as long as the raw material can be dissolved.

[0028] In the present invention, the oper...

Embodiment 1

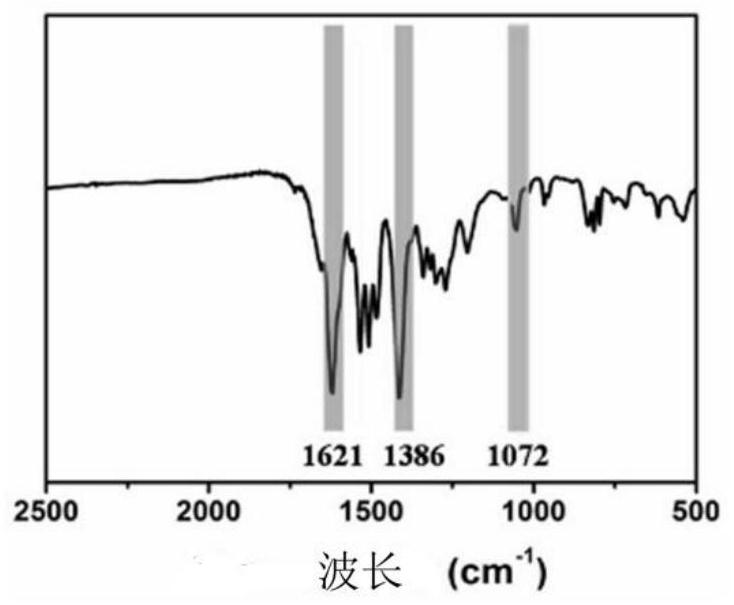

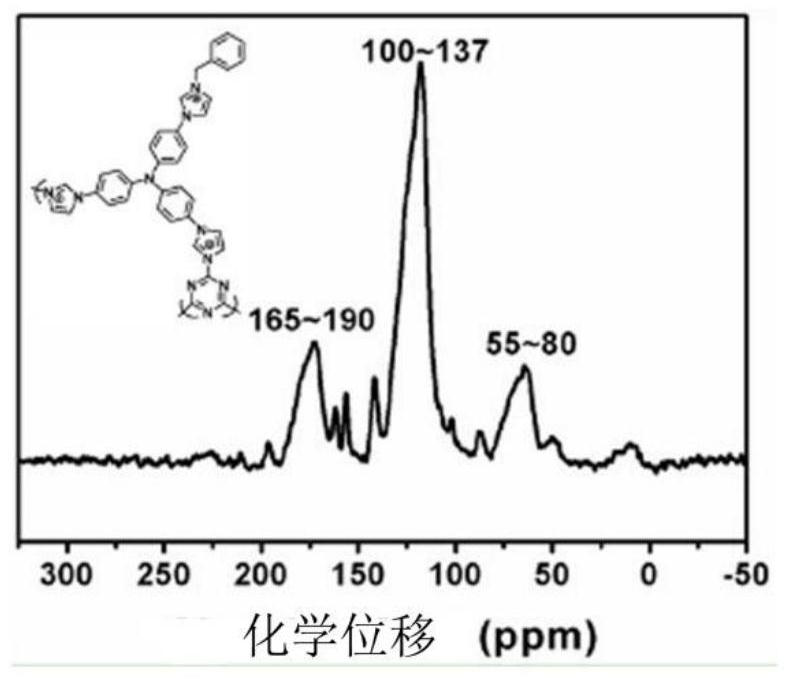

[0046] Weigh 0.355 g of tris(4-imidazolylphenyl) amine and dissolve it in 20 mL of N,N'-dimethylformamide solvent to obtain the first solution; weigh 0.148 g of cyanuric chloride and dissolve it in 20 mL of N,N'-dimethylformamide In the solvent of base formamide, the second solution was obtained; the ratio of the amount of the tris(4-imidazolylphenyl)amine and the cyanuric chloride was 1:1; then the two solutions were mixed, and the mixture was heated at 100° C. The oil bath reaction was carried out for 24 hours, 0.0016 mol of benzyl bromide was added, and the ratio of the amount of the benzyl bromide to the tris(4-imidazolylphenyl)amine was 1:2, and the oil bath reaction was continued at 80°C for 24 hours. Then, the product obtained by the reaction was washed with N,N'-dimethylformamide, acetonitrile and diethyl ether respectively, and dried under vacuum at 60°C for 12h to obtain a yellow powder, which is a porous organic framework material, and the yield was 60%.

[0047] Th...

Embodiment 2

[0051] Weigh 0.355 g of tris(4-imidazolylphenyl) amine and dissolve it in 20 mL of N,N'-dimethylformamide solvent to obtain the first solution; weigh 0.148 g of cyanuric chloride and dissolve it in 20 mL of N,N'-dimethylformamide In the solvent of base formamide, the second solution was obtained; the ratio of the amount of the tris(4-imidazolylphenyl)amine and the cyanuric chloride was 1:1; then the two solutions were mixed, and the mixture was heated at 100° C. The oil bath reaction was carried out for 24 hours, 0.0016 mol of benzyl bromide was added, and the ratio of the amount of the benzyl bromide to the tris(4-imidazolylphenyl)amine was 1:2, and the oil bath reaction was continued at 80°C for 24 hours. Then, the product obtained by the reaction was washed with N,N'-dimethylformamide, acetonitrile and diethyl ether respectively, and dried under vacuum at 60°C for 12h to obtain a yellow powder, which is a porous organic framework material, and the yield was 52%.

[0052] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com