Tea residue paper support and preparation method thereof

A technology of tea residue and paper support, which is applied in pulp beating method, special paper, papermaking and other directions, can solve problems such as poor solvent resistance, shockproof effect, environmental pollution, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

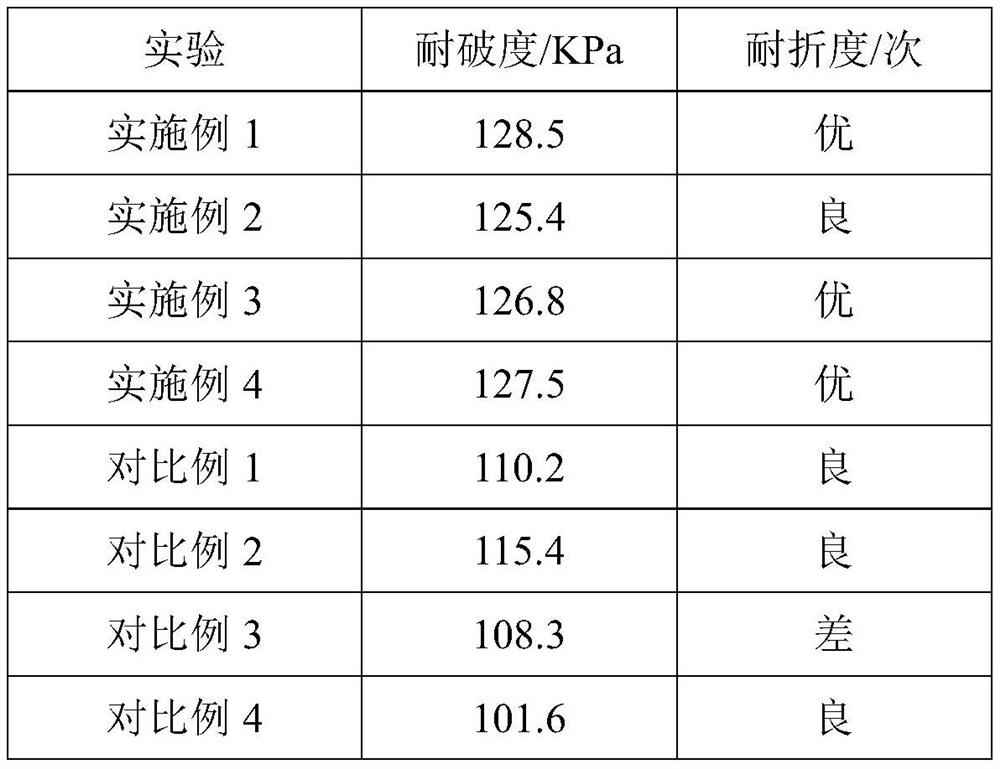

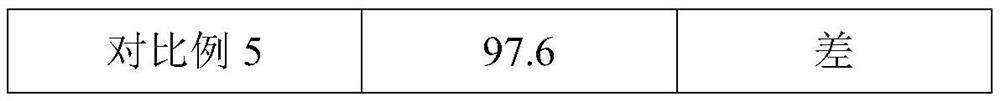

Examples

preparation example Construction

[0042]The second aspect of the present application provides a method for preparing a tea leaves paper holder, which includes the following steps: (1) tea leaves pretreatment: grind and sieve the tea leaves, put the ground tea leaves into 30-50°C water for cleaning, Get the tea leaves, then put them into an oven for drying, and set them aside; (2) Add raw wood pulp, tea leaves, cellulose, and soybean meal into the beating barrel, and add water to the barrel for beating, and the beating degree is 35-40°SR , the time is 60-80 minutes to obtain the pulp stock solution; (3) dilute the obtained pulp stock solution with water to obtain a pulp solution with a concentration of 4-5%; (4) inject the pulp solution into the forming stock tank and pass it through the molding machine The product is shaped, and then shaped by heating and heat preservation with a hot-press setting machine. The temperature of the hot-press setting machine is 220-240°C, and the tea residue paper holder is obtaine...

Embodiment 1

[0049] A paper holder for tea leaves, prepared raw materials in parts by weight: 40 parts of log pulp, 20 parts of tea leaves, 30 parts of soybean meal, 2 parts of cellulose, and 1900 parts of water.

[0050] Raw wood pulp, purchased from Jiangnan wood pulp factory; cellulose is selected from hydroxypropyl methylcellulose, the content of methoxyl group is 28-30%, the content of hydroxypropyl group is 7.0-12%, the viscosity is 50mPa·s, model H811095 , purchased from McLean Reagent Network; soybean meal, item number 005, purchased from Hao Nuo Star Feed Factory, Yuncheng County.

[0051] The tea leaves are green tea leaves, and the green tea is selected from West Lake Longjing.

[0052] The average particle size of tea leaves is 150 mesh.

[0053] The preparation method of the tea leaves paper holder comprises the following steps: (1) tea leaves pretreatment: grind and sieve the green tea, wash the ground tea leaves in 50°C water to obtain tea leaves, and then put them in an ov...

Embodiment 2

[0055] A paper holder for tea leaves, prepared raw materials in parts by weight: 40 parts of log pulp, 20 parts of tea leaves, 30 parts of soybean meal, 2 parts of cellulose, and 1900 parts of water.

[0056] Raw wood pulp, purchased from Jiangnan wood pulp factory; cellulose is selected from hydroxypropyl methylcellulose, the content of methoxyl group is 28-30%, the content of hydroxypropyl group is 7.0-12%, the viscosity is 50mPa·s, model H811095 , purchased from McLean Reagent Network; soybean meal, item number 005, purchased from Hao Nuo Star Feed Factory, Yuncheng County.

[0057] The tea leaves are green tea leaves, and the green tea is selected from West Lake Longjing.

[0058] The average particle size of tea leaves is 400 mesh.

[0059] Refer to Example 1 for the preparation method of the tea leaves paper holder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com