Ordered polystyrene@gold composite microsphere array with dynamically adjustable and controllable gaps as well as preparation method and application thereof

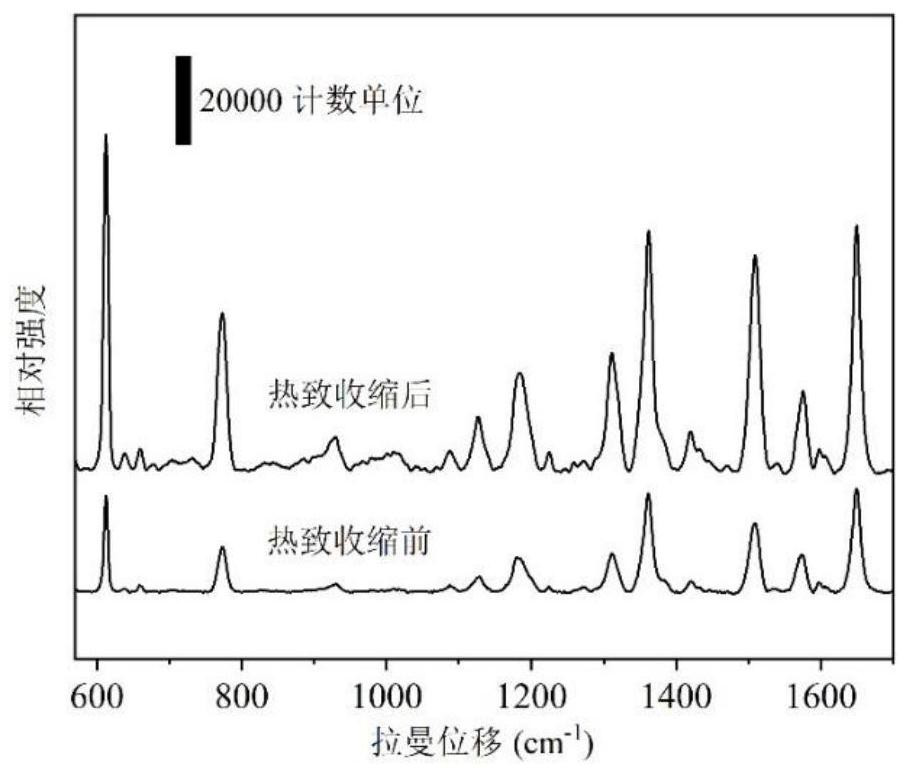

A technology of polystyrene spheres and composite microspheres, which is applied in the direction of measuring devices, instruments, and material analysis through optical means, and can solve the problem of silver nanoparticle morphology, size, gap, and uneven distribution, gap, and arrangement period. Accurate regulation, difficulty in obtaining repeatable SERS signals, etc., to achieve the effect of low production cost, strong repeatability and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The concrete steps of preparation are:

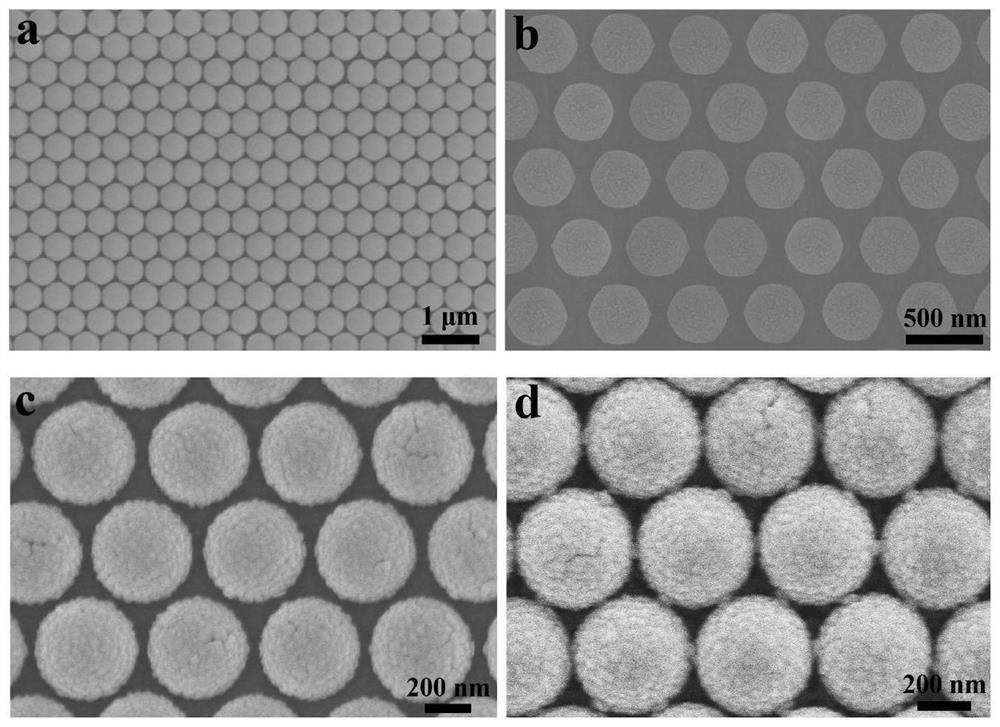

[0045] Step 1, first place the heat-shrinkable polyvinyl chloride substrate in a plasma cleaning machine for cleaning for 2 minutes. A single-layer colloidal crystal template composed of polystyrene colloidal spheres with a diameter of 200 nm is placed on the heat-shrinkable polyvinyl chloride substrate to obtain a heat-shrinkable polyvinyl chloride substrate with a single-layer colloidal crystal template.

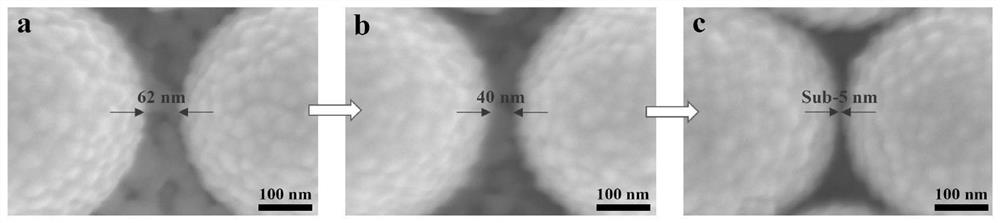

[0046] Step 2, performing plasma etching on the single-layer colloidal crystal template on the heat-shrinkable polyvinyl chloride substrate; wherein, the gas atmosphere during etching is argon, the power is 58W, and the time is 4min. The heat-shrinkable polyvinyl chloride substrate of the single-layer non-close-packed polystyrene sphere template with the distance between two adjacent colloid spheres being 100nm.

[0047] Step 3, use the sputter coating method on the single-layer non-close-packed polystyrene spherical templat...

Embodiment 2

[0049] The concrete steps of preparation are:

[0050] Step 1, first place the heat-shrinkable polyvinyl chloride substrate in a plasma cleaning machine for cleaning for 2 minutes. A single-layer colloidal crystal template composed of polystyrene colloidal spheres with a diameter of 400 nm is placed on the heat-shrinkable polyvinyl chloride substrate to obtain a heat-shrinkable polyvinyl chloride substrate with a single-layer colloidal crystal template.

[0051] Step 2, performing plasma etching on the single-layer colloidal crystal template on the heat-shrinkable polyvinyl chloride substrate; wherein, the gas atmosphere during etching is argon, the power is 58W, and the time is 6.7min. A heat-shrinkable polyvinyl chloride substrate with a single-layer non-close-packed polystyrene sphere template with a distance between two adjacent colloid spheres of 106 nm.

[0052] Step 3, using the sputter coating method on the single-layer non-close-packed polystyrene spherical template ...

Embodiment 3

[0054] The concrete steps of preparation are:

[0055] Step 1, first place the heat-shrinkable polyvinyl chloride substrate in a plasma cleaning machine for cleaning for 2 minutes. A single-layer colloidal crystal template composed of polystyrene colloidal spheres with a diameter of 600 nm is placed on the heat-shrinkable polyvinyl chloride substrate to obtain a heat-shrinkable polyvinyl chloride substrate with a single-layer colloidal crystal template.

[0056] Step 2, performing plasma etching on the single-layer colloidal crystal template on the heat-shrinkable polyvinyl chloride substrate; wherein, the gas atmosphere during etching is argon, the power is 58W, and the time is 9.5min, to obtain A heat-shrinkable polyvinyl chloride substrate with a single-layer non-close-packed polystyrene sphere template with a distance between two adjacent colloid spheres of 113 nm.

[0057] Step 3, using the sputter coating method on the single-layer non-close-packed polystyrene spherical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com