Stannous oxide/graphene heterojunction composite material, preparation method and application thereof, and metal lithium negative electrode taking stannous oxide/graphene heterojunction composite material as host

A technology of graphene composite and stannous oxide, which is applied in the field of metal lithium anode, can solve the problems of poor cycle performance, fast capacity decay and lithium dendrite growth of metal lithium anode, and achieve the improvement of easy growth of lithium dendrites, uniform deposition and The effect of stripping and speeding up the transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

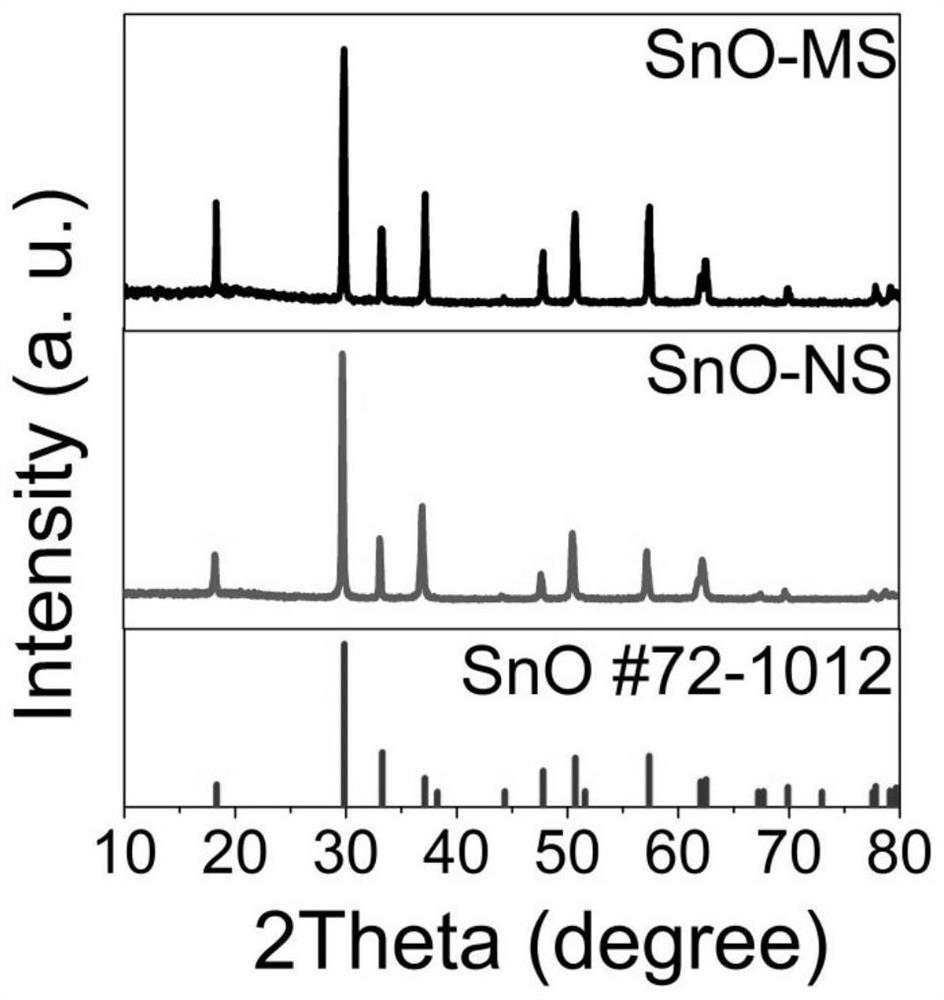

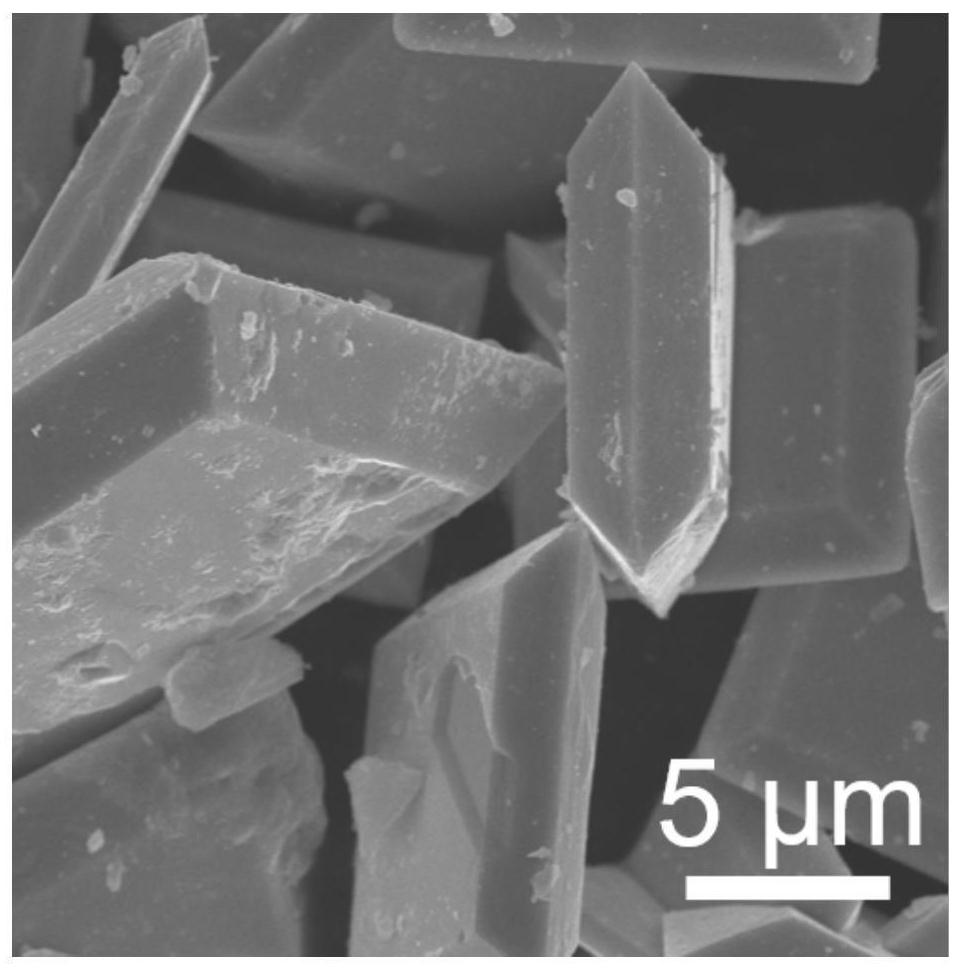

[0039] (1) 0.65g SnCl 2 2H 2 O was dissolved in 20mL deionized water, 0.34g NaOH was weighed and dissolved in 10mL deionized water, NaOH solution was added dropwise under stirring condition, and white Sn 6 o 4 (OH) 4 Suspension, then ultrasonicated at 40kHz 100W for 2h to obtain a brown precipitate, centrifuged at 8000rpm to separate the precipitate, and washed with deionized water and absolute ethanol, the precipitate was dried in a vacuum oven at 90°C for 12h to obtain SnO Micron square (SnO-MS);

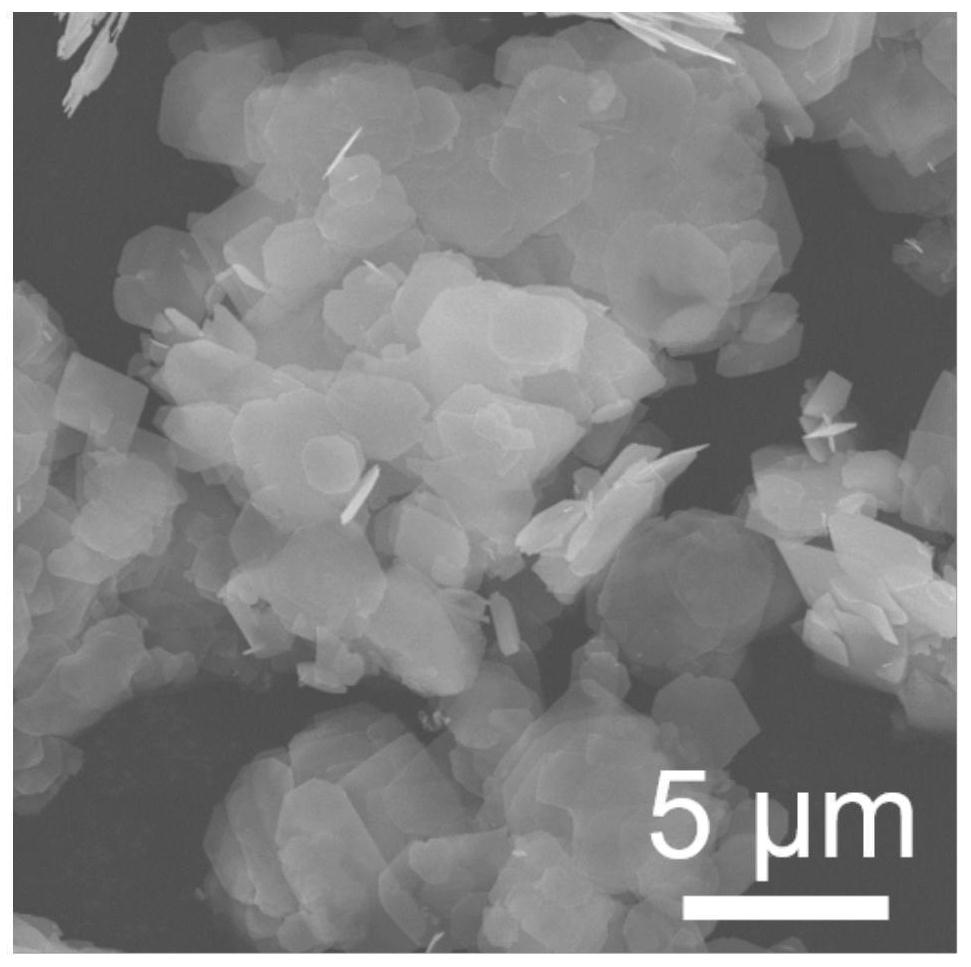

[0040] (2) 0.65g SnCl 2 2H 2 O and 1g of PVP were dissolved in 20mL deionized water, 0.34g NaOH was weighed and dissolved in 10mL deionized water, NaOH solution was added dropwise under stirring condition, and white Sn was generated after 0.5h reaction. 6 o 4 (OH) 4 Suspension, and then ultrasonicated at 40kHz 100W for 2h to obtain a brown precipitate, centrifuged at 8000rpm to separate the precipitate, washed with deionized water and absolute ethanol, and dried in a vacuu...

Embodiment 2

[0054] (1) 0.65g SnCl 2 2H 2 O was dissolved in 20mL deionized water, 0.44g NaOH was weighed and dissolved in 10mL deionized water, NaOH solution was added dropwise under stirring condition, and white Sn 6 o 4 (OH) 4 Suspension, and then ultrasonicated at 40kHz 100W for 2h to obtain a brown precipitate, centrifuged at 8000rpm to separate the precipitate, and washed with deionized water and absolute ethanol, the precipitate was dried in a vacuum oven at 90°C for 12h to obtain SnO -MS;

[0055] (2) 0.65g SnCl 2 2H 2 O and 5g PVP were dissolved in 20mL deionized water, 0.44g NaOH was weighed and dissolved in 10mL deionized water, NaOH solution was added dropwise under stirring conditions, and white Sn was generated after 0.5h reaction. 6 o 4 (OH) 4 Suspension, and then ultrasonicated at 40kHz 100W for 2h to obtain a brown precipitate, centrifuged at 8000rpm to separate the precipitate, and washed with deionized water and absolute ethanol, the precipitate was dried in a va...

Embodiment 3

[0061](1) 0.65g SnCl 2 2H 2 O was dissolved in 20mL deionized water, 0.4g NaOH was weighed and dissolved in 10mL deionized water, NaOH solution was added dropwise under stirring condition, and white Sn 6 o 4 (OH) 4 Suspension, and then ultrasonicated at 40kHz 100W for 2h to obtain a brown precipitate, centrifuged at 8000rpm to separate the precipitate, and washed with deionized water and absolute ethanol, the precipitate was dried in a vacuum oven at 90°C for 12h to obtain SnO -MS;

[0062] (2) 0.65g SnCl 2 2H 2 O and 3g PVP were dissolved in 20mL deionized water, 0.4g NaOH was weighed and dissolved in 10mL deionized water, NaOH solution was added dropwise under stirring condition, and white Sn was generated after 0.5h reaction. 6 o 4 (OH) 4 Suspension, and then ultrasonicated at 40kHz 100W for 2h to obtain a brown precipitate, centrifuged at 8000rpm to separate the precipitate, and washed with deionized water and absolute ethanol, the precipitate was dried in a vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com