Firefighting device based on unmanned aerial vehicle

A fire-fighting device and unmanned aerial vehicle technology, applied in the field of unmanned aerial vehicles, can solve problems such as single function, unfavorable use of unmanned aerial vehicles, unsatisfactory fire extinguishing effect, etc., achieve uniform and dense film layer, convenient and stable control, improve mechanical performance and The effect of water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

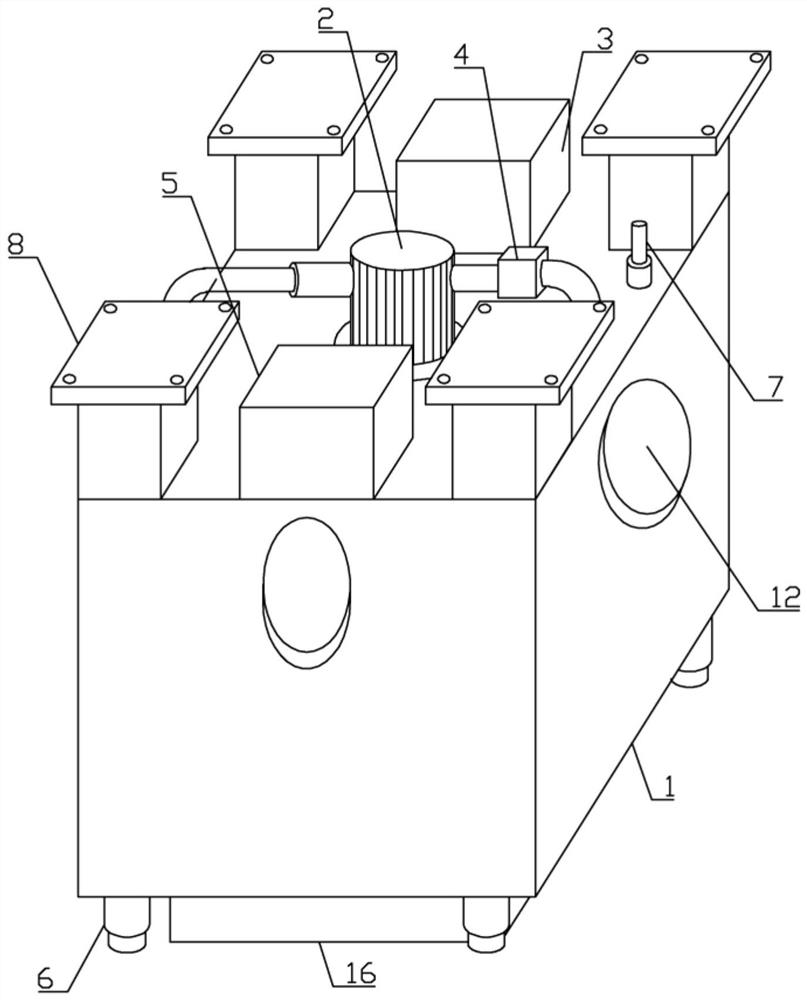

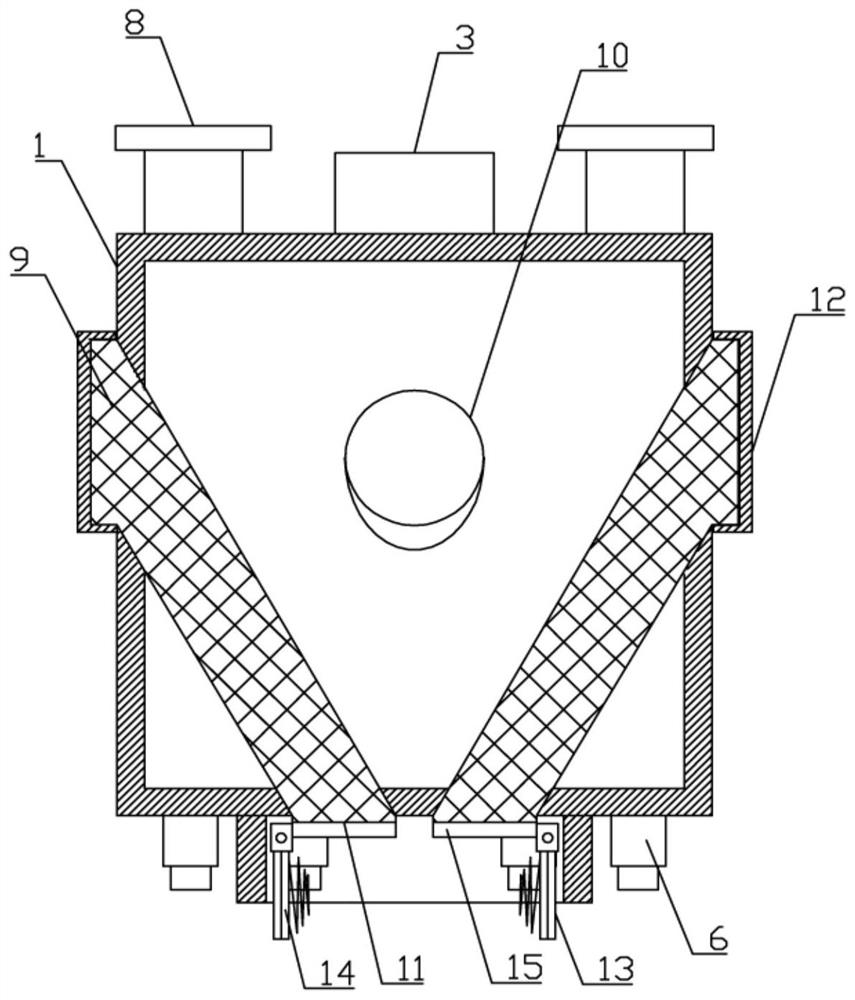

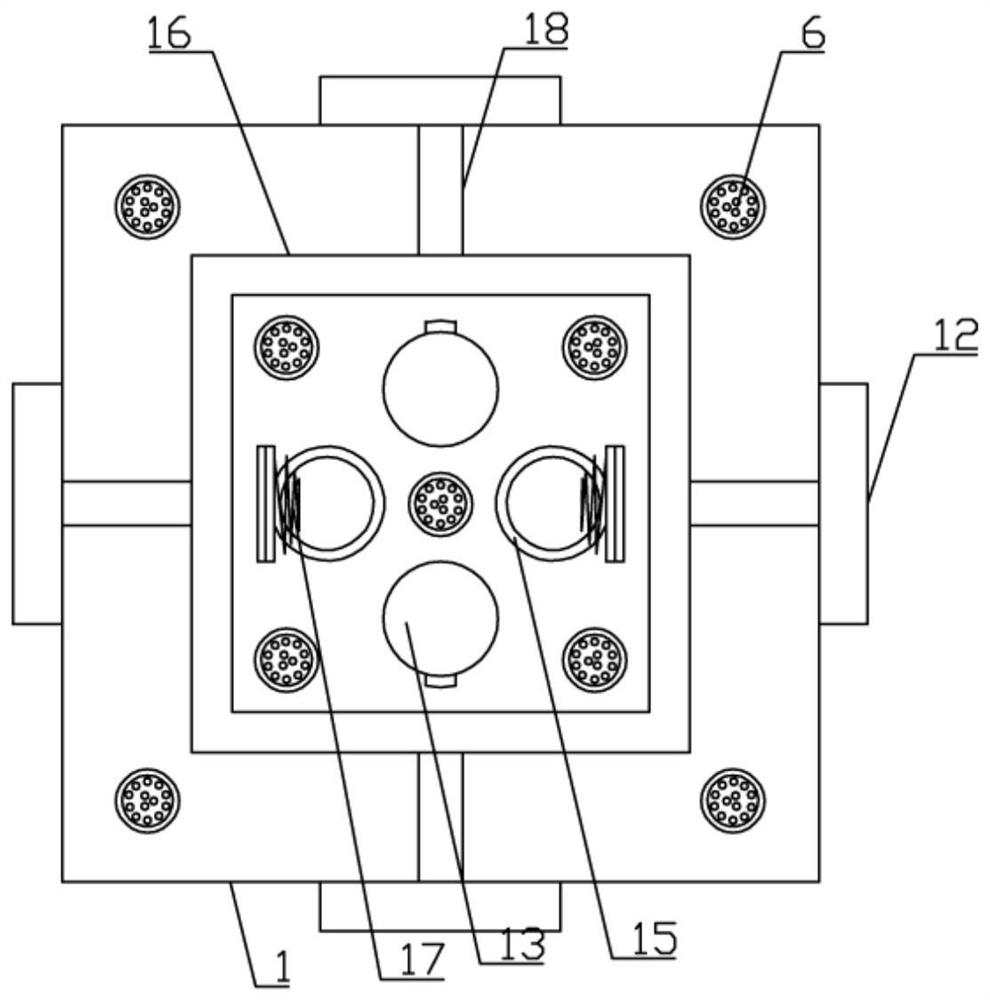

[0034] Such as Figure 1 to Figure 5 As shown, a fire-fighting device based on an unmanned aerial vehicle includes a water tank 1, a booster pump 2, a PLC control cabinet 3, a solenoid valve 4, and a power supply for powering the booster pump 2, the PLC control cabinet 3, and the solenoid valve 4 Box 5, booster pump 2, PLC control cabinet 3 and power supply box 5 are all installed on the outer top surface of water tank 1, solenoid valve 4 and booster pump 2 are electrically connected to PLC control cabinet 3 respectively, and the water inlet of booster pump 2 The water outlet of the solenoid valve 4 is connected through the pipeline, the water inlet of the solenoid valve 4 is connected with the water tank 1 through the pipeline, and the water outlet of the booster pump 2 is connected with a plurality of high-pressure nozzles 6 through the pipeline, and the plurality of high-pressure nozzles 6 are installed in the water tank 1 On the outer bottom surface, the outer top surface ...

Embodiment 2

[0045] On the basis of Embodiment 1, this embodiment provides the processing method of the aluminum alloy waterproof intermediate layer as follows:

[0046] The aluminum alloy waterproof interlayer is immersed in NaOH and NaOH with a molar ratio of 4:1 3 PO 4 After soaking in the mixed solution for 5 minutes, rinse the aluminum alloy waterproof intermediate layer with deionized water for 3 minutes, then rinse with ethanol solution for 5-10 minutes, and then dry it for later use; immerse the treated aluminum alloy waterproof intermediate layer in a polishing solution at 100°C Medium polishing for 10s, and then repeatedly rinse the aluminum alloy waterproof intermediate layer with deionized water, wherein the polishing solution includes 400g / L NaOH, 150g / L NaNO 2 , 30g / L NaF, 20g / L Na 3 PO 4 ; Immerse the treated aluminum alloy waterproof intermediate layer in the mixed acid electrolyte, and then linearly adjust the oxidation voltage to a preset value of 120V within 30s, with...

Embodiment 3

[0048] On the basis of Embodiment 1, this embodiment provides the processing method of the aluminum alloy waterproof intermediate layer as follows:

[0049] The aluminum alloy waterproof interlayer is immersed in NaOH and NaOH with a molar ratio of 4:1 3 PO 4 After soaking in the mixed solution for 7 minutes, rinse the aluminum alloy waterproof intermediate layer with deionized water for 4 minutes, then rinse with ethanol solution for 8 minutes, and then dry it for later use; immerse the treated aluminum alloy waterproof intermediate layer in a polishing solution at 110°C for polishing 10s, then repeatedly rinse the aluminum alloy waterproof intermediate layer with deionized water, wherein the polishing solution includes 450g / L NaOH, 160g / L NaNO 2 , 37g / L NaF, 22g / L Na 3 PO 4 ; Immerse the treated aluminum alloy waterproof intermediate layer in the mixed acid electrolyte, and then linearly adjust the oxidation voltage to a preset value of 120V within 30s, and the peak curre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com