Spraying preparation method for aluminum profile processing

A technology for aluminum profile processing and aluminum profiles, which is applied to the surface coating liquid device, pretreatment surface, coating, etc., can solve the problem of poor bonding between the sprayed coating and the surface of the aluminum profile, bubbles and wrinkles on the surface of the aluminum profile It is easy to produce problems such as paint adhesion needs to be improved, so as to achieve better spraying effect, prevent bubbles and wrinkles, and increase the protection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

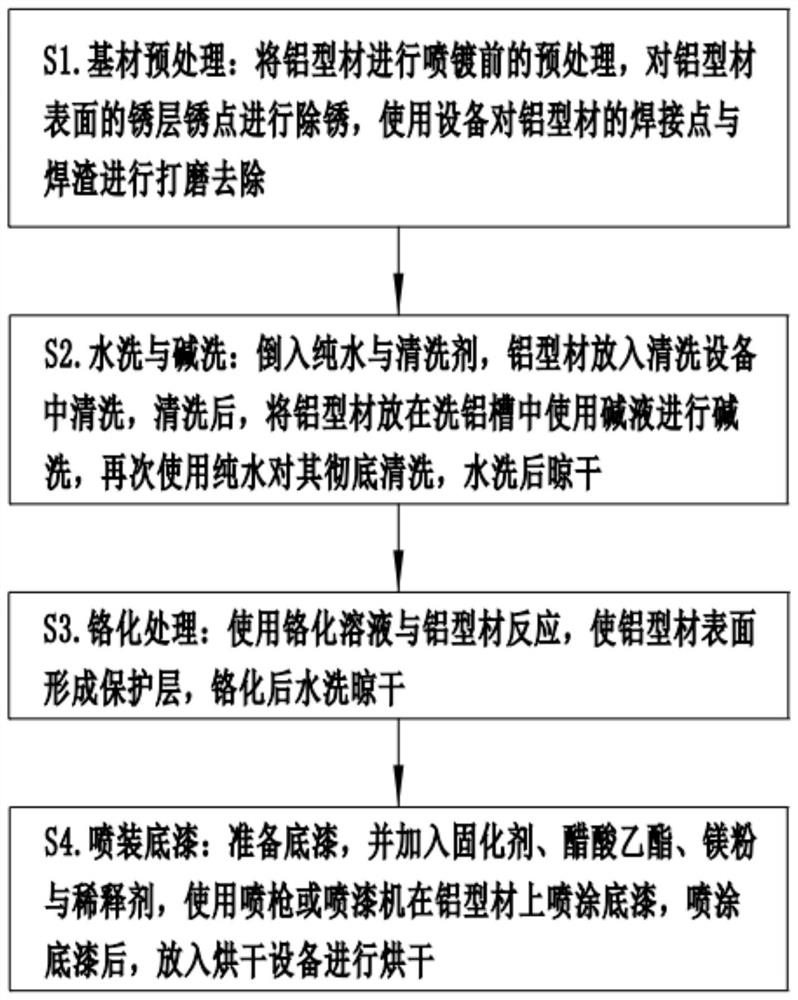

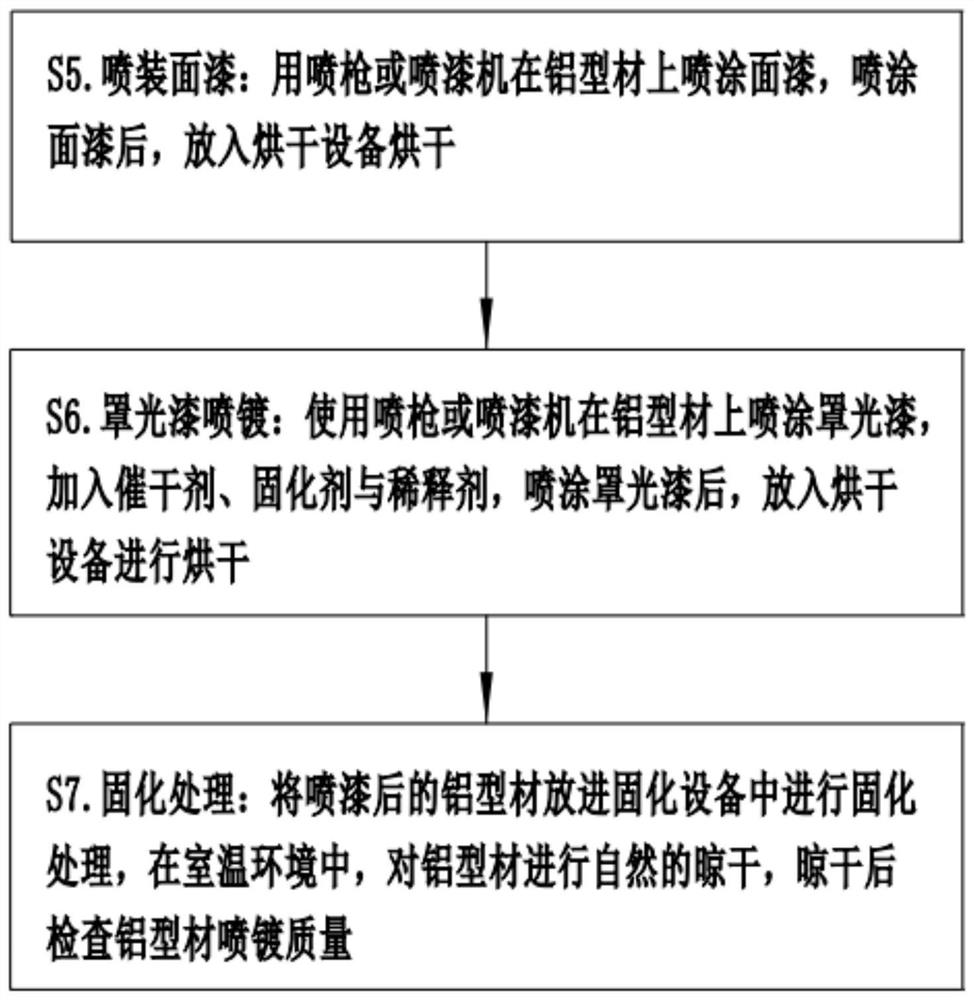

[0032] A spraying preparation method for processing aluminum profiles, comprising the following steps:

[0033] S1. Substrate pretreatment: pretreat the aluminum profile before spraying, derust the rust layer and rust spots on the surface of the aluminum profile, use equipment to remove the welding points and welding slag of the aluminum profile, and use a rust remover To remove the rust layer and rust spots on the surface of aluminum profiles, high-efficiency corrosion inhibitors are added to the rust remover, and the welding points and welding slag are removed by grinding equipment, and the dust collection equipment is used to reduce dust flying while grinding;

[0034] S2. Water washing and alkali washing: Pour pure water and cleaning agent into the cleaning equipment. The cleaning agent is an industrial degreasing cleaning agent. Put the aluminum profiles into the cleaning equipment for cleaning. After cleaning, put the aluminum profiles in the aluminum washing tank for use...

Embodiment 2

[0041] A spraying preparation method for processing aluminum profiles, comprising the following steps:

[0042] S1. Substrate pretreatment: pretreat the aluminum profile before spraying, derust the rust layer and rust spots on the surface of the aluminum profile, use equipment to remove the welding points and welding slag of the aluminum profile, and use a rust remover To remove the rust layer and rust spots on the surface of aluminum profiles, high-efficiency corrosion inhibitors are added to the rust remover, and the welding points and welding slag are removed by grinding equipment, and the dust collection equipment is used to reduce dust flying while grinding;

[0043] S2. Water washing and alkali washing: Pour pure water and cleaning agent into the cleaning equipment. The cleaning agent is an industrial degreasing cleaning agent. Put the aluminum profiles into the cleaning equipment for cleaning. After cleaning, put the aluminum profiles in the aluminum washing tank for use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com