Automatic tissue specimen sampling equipment

A tissue specimen, automatic sampling technology, applied in the direction of cap, liquid handling, liquid distribution, conveying or transfer device, etc., can solve problems such as low efficiency, and achieve the effect of high degree of automation and high packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

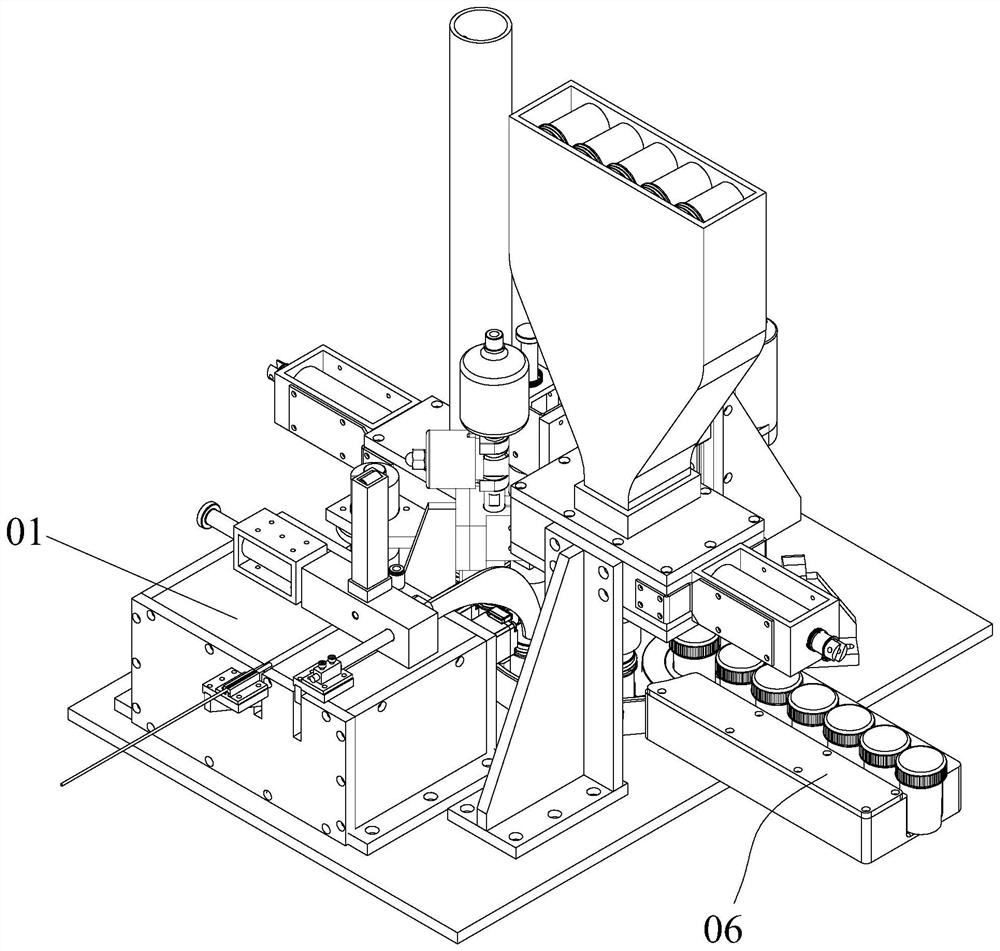

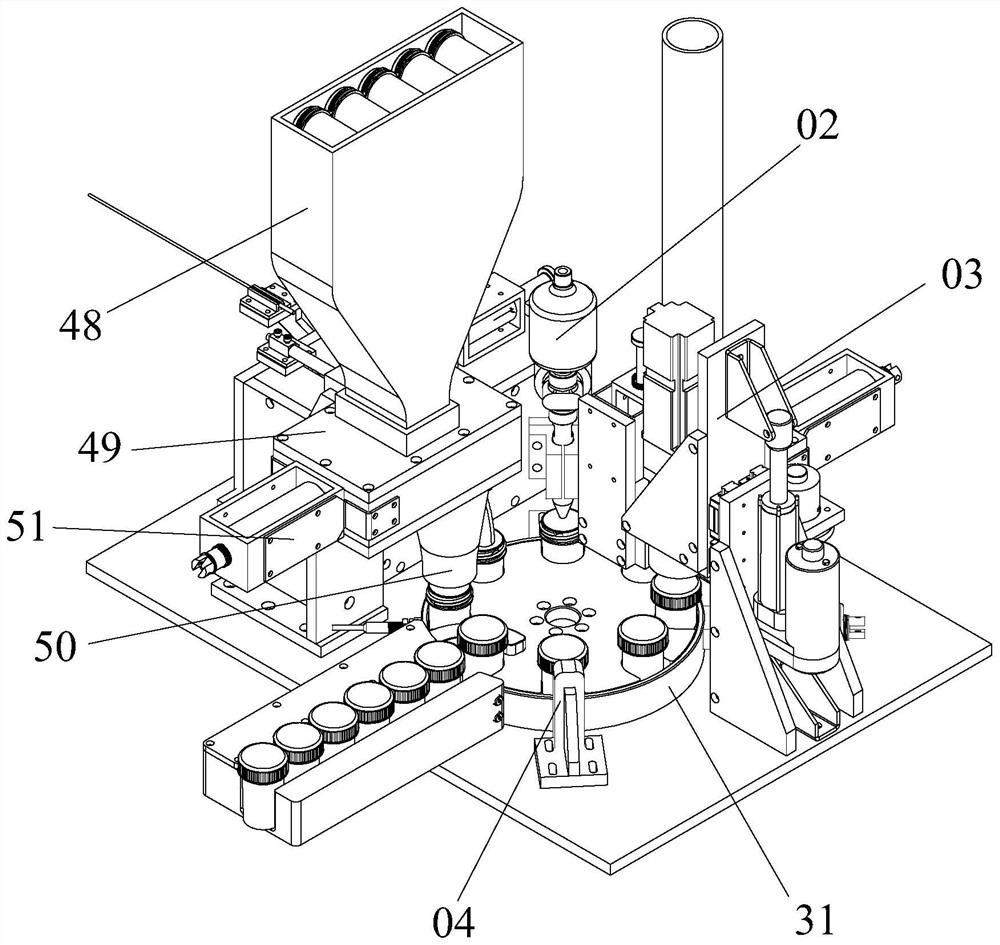

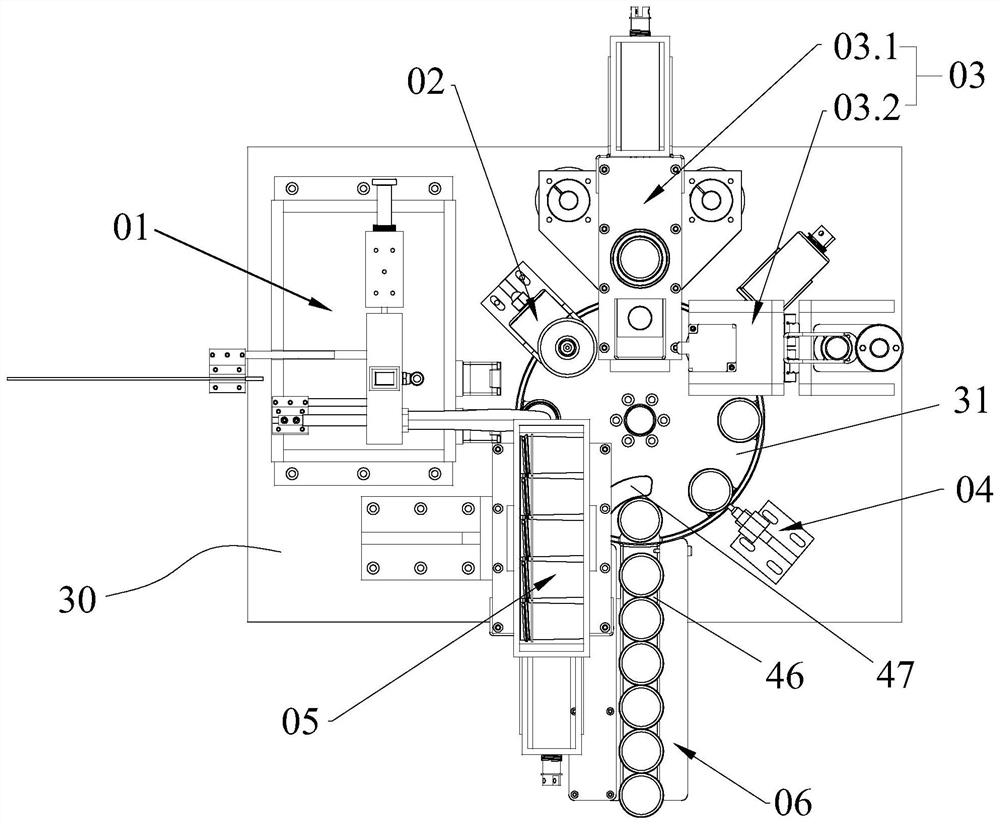

[0055] Such as figure 1 , 2 , 3, the present invention provides a tissue sample automatic sampling device, including a bottom plate 30, on which a collecting mechanism 01, a liquid filling structure 02 and a capping mechanism 03 are sequentially arranged, and a transmission mechanism is also arranged on the bottom plate 30 , which is used to drive the specimen collection container through the stations where the collection mechanism 01, liquid filling structure 02 and capping mechanism 03 are located in order to realize the automatic collection of tissue specimens, automatic liquid filling, automatic capping and other processes, replacing the prior art The manual collection of tissue samples, manual liquid filling, manual capping and other operations are faster and more efficient.

[0056] In this structure, the collection mechanism 01, the liquid filling structure 02 and the capping mechanism 03 can be arranged along the same straight line, that is, a linear assembly line is ...

Embodiment 2

[0091] Such as Figure 11 As shown, the structure of this implementation is basically the same as that of Embodiment 1, and the only difference is the specific structural form of the separation component. The separation component in the first embodiment relies on the adsorption of the vacuum equipment to absorb and adhere the tissue specimen on the biopsy forceps 110 to the sample tube 100. Since there are relatively few vacuum equipment in actual production, another method is adopted in this embodiment. A separate form, as follows:

[0092] In this embodiment, the separation mechanism includes an air pipe 12 and an air blowing device 60. The air blowing device 60 is arranged on the installation block 6 at a position corresponding to the first station, specifically the position corresponding to the first through hole 6.2. The air device 60 is provided with a joint 60.1 connected with an external air pump. One end of the air pipe 12 is connected to the other end of the mounti...

Embodiment 3

[0094] The structure of this embodiment is the same as that of Embodiment 1, the only difference is that the specific structures of the positioning component and the separation component are different; specifically, as Figure 12 , 13 As shown, the positioning component in this embodiment includes:

[0095] The mounting frame 10 is provided with a positioning plate 11 for rotation on the mounting frame 10, and at least one accommodating groove 14 for accommodating the sample tube 100 is provided on the outer wall of the positioning plate 11, and the second driving mechanism drives the positioning plate 11 to rotate so that The sample tube 100 in the holding tank 14 is switched between the first station and the second station. In this embodiment, the second driving mechanism is a rotary stepping motor, and the output shaft of the rotary stepping motor is connected to the positioning disc 11, and the positioning disc 11 is driven to rotate in a circumferential direction by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com