Method for preparing carbon molecular sieve from biological semi-coke

A carbon molecular sieve and semi-coke technology, which is applied in the field of carbon molecular sieve preparation by using biological semi-coke, can solve the problems of poor kinetic separation effect, environmental pollution, complex process, etc., and achieve low price, high micropore volume and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

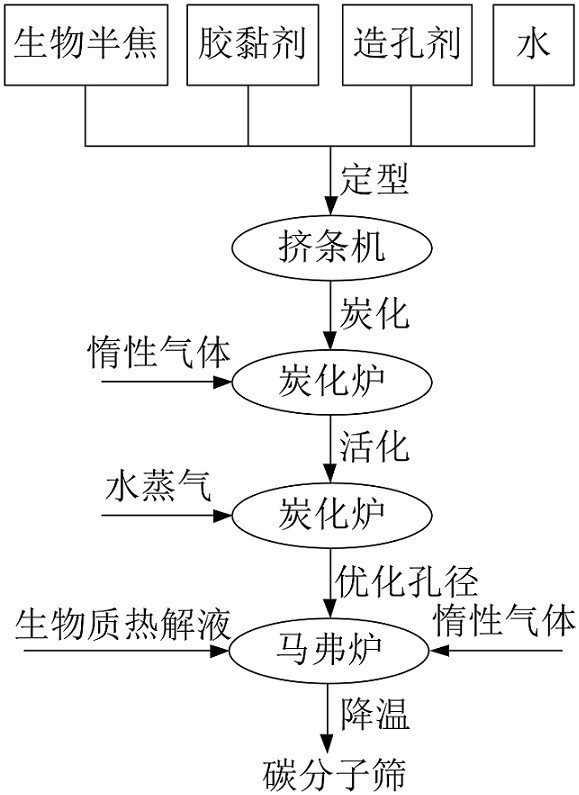

Method used

Image

Examples

Embodiment 1

[0036] In parts by weight, 50 parts of bio-coke, 10 parts of adhesive, 10 parts of pore-forming agent, 5 parts of water and 25 parts of biomass pyrolysis solution are weighed.

[0037] Then process and produce according to the following specific methods:

[0038] (1) Forming: Knead biological semi-coke, adhesive, pore-forming agent and water in a kneader according to the proportion, and extrude them in the extruder to shape them. After natural air drying, cut the strips and granulate to a diameter of 3mm. particles;

[0039] (2) Carbonization: Put the formed particles into a carbonization furnace, raise the temperature to 750°C at a heating rate of 5°C / min under the protection of an inert gas, and keep the temperature for 60 minutes to volatilize and carbonize organic matter; a slower heating rate can Completely volatilize organic matter;

[0040] (3) Activation: Introduce water vapor into the carbonization furnace for activation. The mass ratio of water vapor and bio-semi-c...

Embodiment 2

[0047] In parts by weight, 55 parts of bio-coke, 12 parts of adhesive, 12 parts of pore-forming agent, 6 parts of water, and 15 parts of biomass pyrolysis solution were weighed.

[0048] Then process and produce according to the following specific methods:

[0049](1) Molding: Knead the biological semi-coke, adhesive, pore-forming agent and water in the kneader according to the proportion, and extrude the strips in the extruder to shape them. After natural air drying, the strips are cut and sized to a diameter of 2mm. particles.

[0050] (2) Carbonization: put the shaped particles into a carbonization furnace, and raise the temperature to 720°C at a rate of 5°C / min under the protection of an inert gas, and keep the temperature constant for 40 minutes to volatilize and carbonize organic matter.

[0051] (3) Activation: Introduce water vapor into the carbonization furnace for activation. The mass ratio of water vapor to bio-semi-coke is 3:1, and the activation time is 50 minute...

Embodiment 3

[0058] In terms of parts by weight, 40 parts of bio-coke, 15 parts of adhesive, 15 parts of pore-forming agent, 10 parts of water and 20 parts of biomass pyrolysis solution are weighed.

[0059] Then process and produce according to the following specific methods:

[0060] (1) Forming: Knead biological semi-coke, adhesive, pore-forming agent and water in a kneader according to the proportion, and extrude them in the extruder to shape them. After natural air drying, cut the strips and granulate to a diameter of 3mm. particles.

[0061] (2) Carbonization: Put the formed particles into a carbonization furnace, and under the protection of an inert gas, heat up to 700°C at a rate of 6°C / min, and keep the temperature constant for 60 minutes to volatilize and carbonize organic matter.

[0062] (3) Activation: Introduce water vapor into the carbonization furnace for activation. The mass ratio of water vapor to bio-semi-coke is 3:1, and the activation time is 60 minutes, so that the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com