Process for extracting ammonium chloride from waste etching liquid and evaporation and concentration system thereof

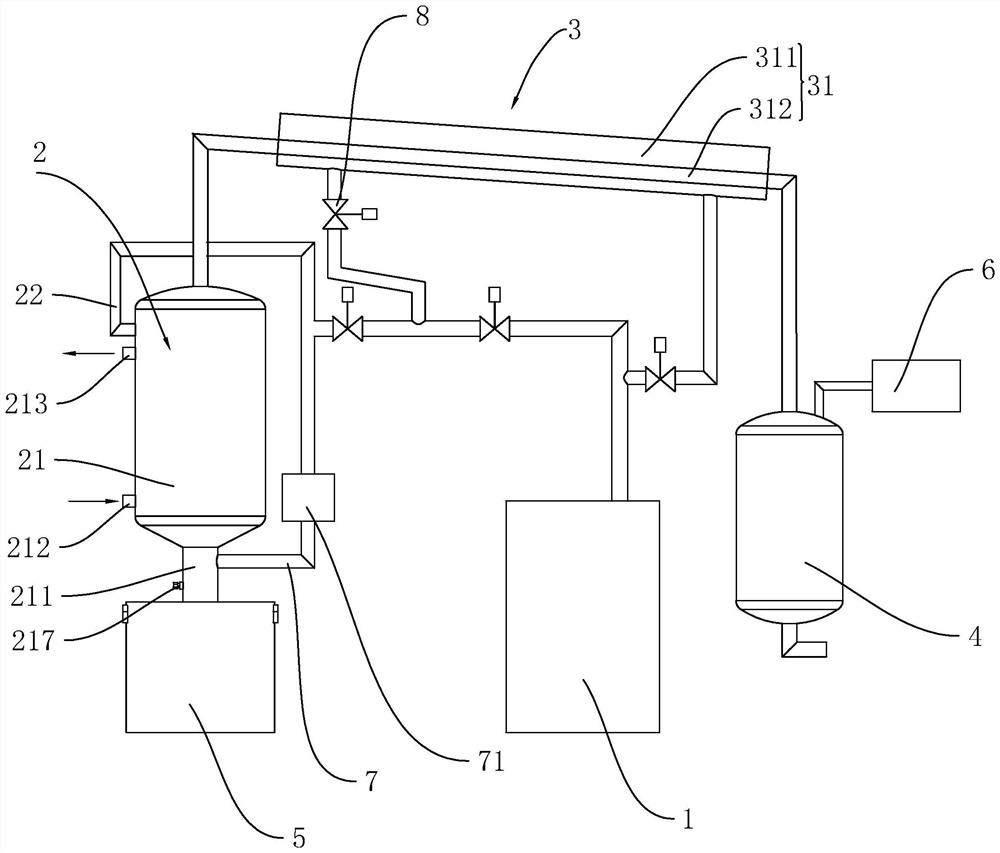

An evaporative concentration system and a technology for waste etching solution, which are applied in the field of technology and its evaporative concentration system, can solve the problems of low value and low purity of ammonium chloride, and achieve the effects of improving recovery rate, low energy consumption and good adsorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

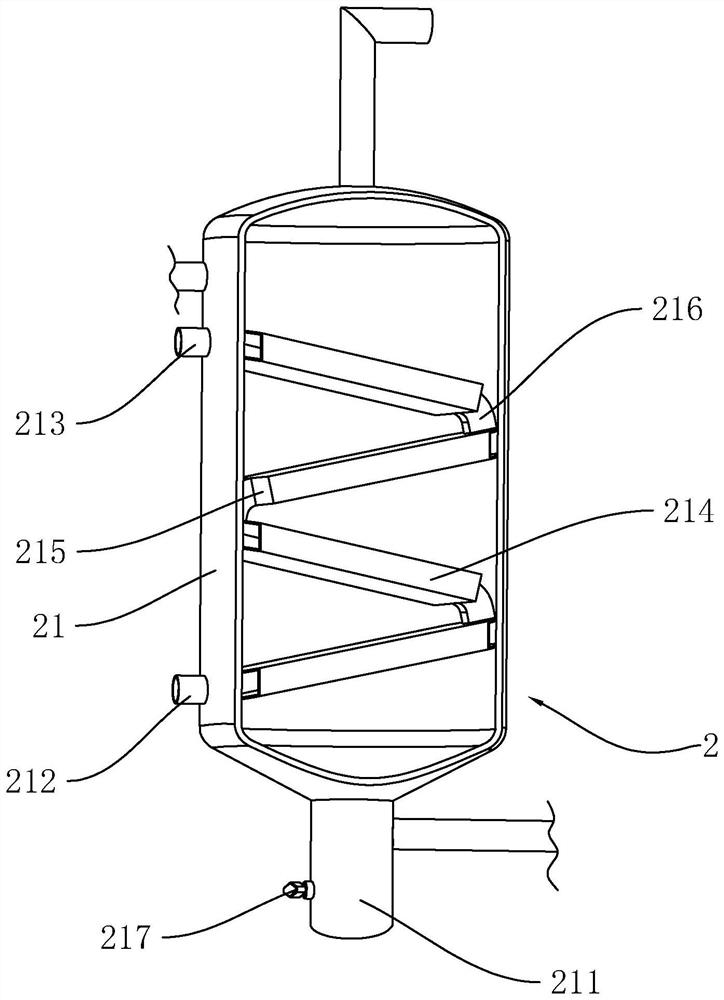

Method used

Image

Examples

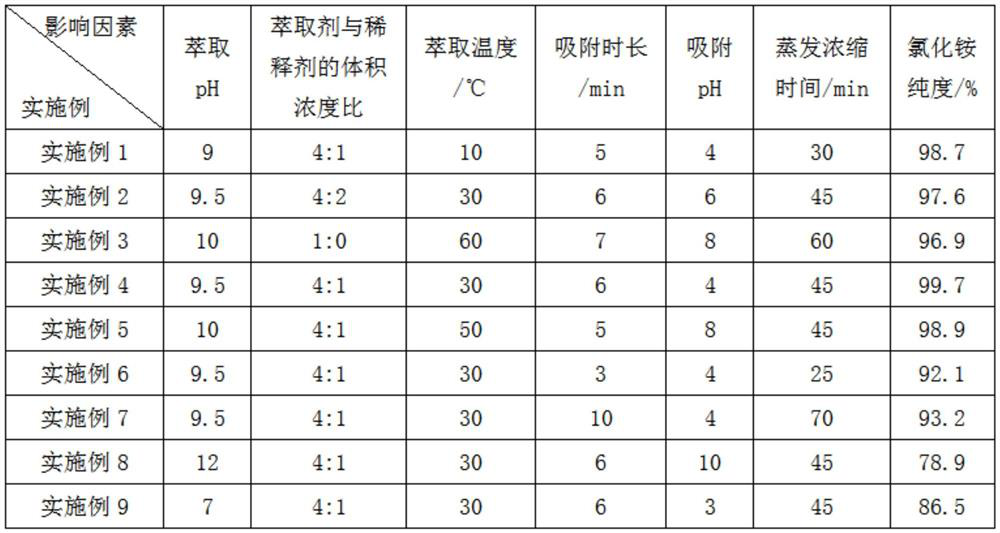

Embodiment 1

[0039] In order to obtain the higher ammonium chloride product of purity, the application proposes a kind of technique of extracting ammonium chloride from waste etching solution, at least comprises the following steps:

[0040] S1. Filtrating the alkaline waste etching solution to remove suspended impurities and adjusting the pH to 9 to obtain solution a;

[0041] S2. The solution a enters the packed extraction tower for extraction, and the extractant and the diluent with a volume concentration ratio of 4:1 are introduced into the packed extraction tower in advance, and the extraction temperature is set to 10° C. to obtain the organic phase b and the raffinate c;

[0042] S3, adding hydrochloric acid to the raffinate c for conditioning to obtain a solution d;

[0043] S4, in the fixed bed adsorption equipment, adjust the pH value to 4, adopt L-glutamic acid chelating resin to adsorb the heavy metal ion in the solution d for 5min, and obtain the ammonium chloride solution e an...

Embodiment 2

[0056] S1. Filter the alkaline waste etching solution to remove suspended impurities and adjust the pH value to 9.5 to obtain solution a;

[0057] S2. The solution a enters the packed extraction tower for extraction, and the extraction agent and the diluent with a volume concentration ratio of 4:2 are introduced into the packed extraction tower in advance, and the extraction temperature is set to 30° C. to obtain the organic phase b and the raffinate c;

[0058] S3, adding hydrochloric acid to the raffinate c for conditioning to obtain a solution d;

[0059] S4, in the fixed bed adsorption equipment, adjust the pH to be 6, adopt L-glutamic acid chelating resin to adsorb the heavy metal ion in the solution d for 6min, obtain the ammonium chloride solution e and the desorption liquid f;

[0060] S5. Obtain ammonium chloride concentrated solution g by evaporating and concentrating the ammonium chloride solution e, wherein the evaporating and concentrating time is 45 min;

[0061...

Embodiment 3

[0064] S1. Filtrating the alkaline waste etching solution to remove suspended impurities and adjusting the pH value to 10 to obtain solution a;

[0065] S2. The solution a enters the packed extraction tower for extraction, and only imports the extractant of equal concentration into the packed extraction tower in advance, and sets the extraction temperature to 60° C. to obtain the organic phase b and the raffinate c;

[0066] S3, adding hydrochloric acid to the raffinate c for conditioning to obtain a solution d;

[0067] S4, in the fixed bed adsorption equipment, adjust the pH value to be 8, adopt the L-glutamic acid chelating resin to adsorb the heavy metal ion in the solution d for 7min, obtain the ammonium chloride solution e and the desorption liquid f;

[0068] S5. Obtain ammonium chloride concentrated solution g by evaporating and concentrating the ammonium chloride solution e, wherein the evaporating and concentrating time is 60 min;

[0069] S6. Cooling and crystalliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com