Novel process for preparing novel liquid organic fertilizer from waste biomass

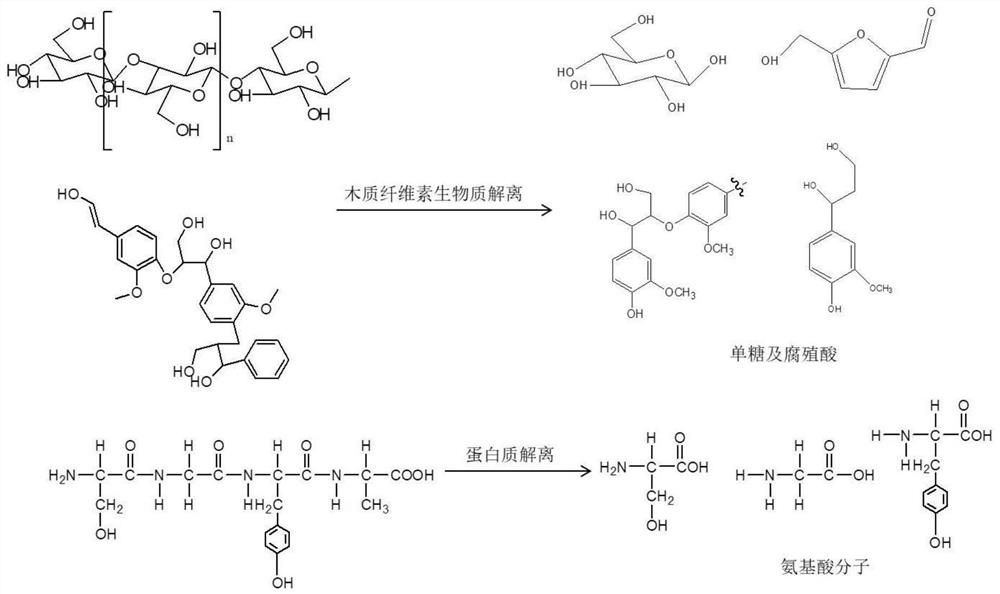

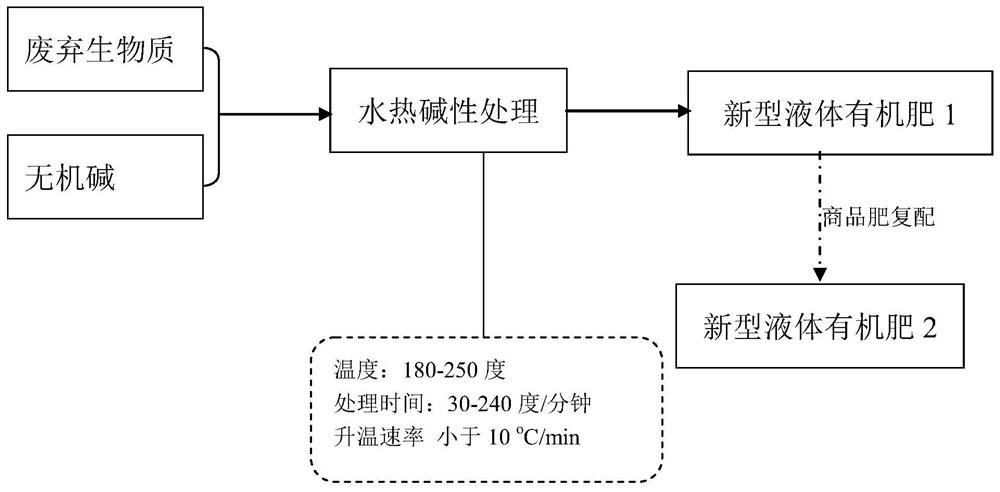

A technology for discarding biomass and liquid organic fertilizers, applied in liquid fertilizers, organic fertilizers, animal carcass fertilizers, etc., can solve the problems of incorrect treatment, untimely, environmental pollution, etc., and achieve complete nutrient, high content and high fertilizer efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Preparation of new liquid organic fertilizer

[0023] The waste biomass is kitchen waste (collected from kitchen waste collection bins in Weigong Village Community, Beijing). Crush fresh kitchen waste (with a water content of about 89%) to less than 20mm and set aside.

[0024] 1) Mix the pulverized kitchen waste and potassium carbonate at a ratio of 1:0.5 and put them into a hydrothermal reactor;

[0025] 2) Heat the reactor to 190°C at a heating rate of 5°C / min under stirring conditions and keep it for 80 minutes; after the hydrothermal treatment is completed, the reactor is cooled by an electric fan and internal circulating cooling water, and after cooling, the solid-liquid separation removes a small amount of The solid product is the novel liquid organic fertilizer.

[0026] 2. Determination of fertilizer efficiency of liquid organic fertilizer

[0027] The comprehensive performance evaluation indicators of liquid organic fertilizers include total nutrient con...

Embodiment 2

[0031] In the preparation of the new liquid organic fertilizer, the waste biomass was respectively used duck slaughter waste (offal, fur, etc.).

[0032] 1. Preparation of Liquid Organic Fertilizer

[0033] 1) Put the slaughter waste and potassium hydroxide into a hydrothermal reaction kettle in a weight ratio of 1:1.

[0034] 2) Heat the reactor to 160°C at a heating rate of 5°C / min under stirring conditions and keep it for 120 minutes; after the hydrothermal treatment is completed, the reactor is cooled by an electric fan and internal circulating cooling water, and after cooling, the solid-liquid separation removes a small amount of The solid product is the novel liquid organic fertilizer.

[0035] 2. The method for measuring the fertilizer efficiency of liquid organic fertilizer is the same as in Example 1.

[0036] Table 2. Product indicators of new liquid organic fertilizer prepared from duck slaughter waste

[0037] project index Organic matter conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com