Rare earth composite coated titanium dioxide as well as preparation method and application thereof

A rare earth composite, titanium dioxide technology, applied in the application, chemical instruments and methods, household appliances, etc., can solve the problems of insufficient light resistance, yellowing, etc., and achieve the effect of good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

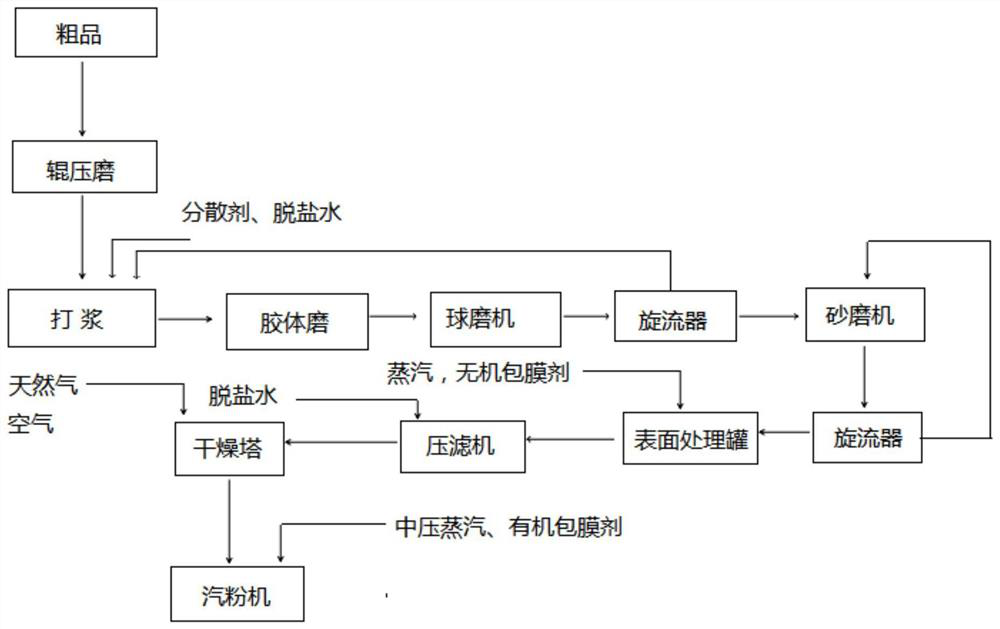

[0041] The preparation method of the rare earth composite coated titanium dioxide in this embodiment includes pulping, roller mill dry grinding, inorganic surface treatment, washing, drying, jet milling and packaging, specifically including the following steps:

[0042] Step S101, the crude titanium dioxide is pulverized by a roller mill and then enters the beating tank, and at the same time, desalted water and dispersant are added, and stirred evenly to obtain a crude titanium dioxide slurry, which is then wet-milled by a ball mill, and subjected to cyclone classification , the qualified slurry is transferred to the next process, and the unqualified slurry is transferred back to the beating tank for circular grinding, requiring control of 325 mesh sieve; the concentration of titanium dioxide crude product slurry is controlled at 900g / L, and the cyclone pressure is 0.4 MPa, 0.4% of residue on 325 mesh sieve after cyclone; dispersant is PAAS, and the addition amount is controlle...

Embodiment 2

[0054] The preparation method of the rare earth composite coated titanium dioxide of the present embodiment specifically comprises the following steps:

[0055] Step S101, the crude titanium dioxide is pulverized by a roller mill and then enters the beating tank, and at the same time, desalted water and dispersant are added, and stirred evenly to obtain a crude titanium dioxide slurry, which is then wet-milled by a ball mill, and subjected to cyclone classification , the qualified slurry is transferred to the next process, and the unqualified slurry is transferred back to the beating tank for circular grinding, requiring control of 325 mesh sieve residue; the concentration of the crude titanium dioxide slurry is controlled at 700g / L, and the cyclone pressure is 0.25 MPa, 0.5% of residue on 325 mesh sieve after cyclone; dispersant is hexametaphosphoric acid, and the addition is controlled at 0.2%;

[0056] Step S102, grind the slurry obtained in step S101 through a sand mill; a...

Embodiment 3

[0067]The preparation method of the rare earth composite coated titanium dioxide of the present embodiment specifically comprises the following steps:

[0068] Step S101, the crude titanium dioxide is pulverized by a roller mill and then enters the beating tank, and at the same time, desalted water and dispersant are added, and stirred evenly to obtain a crude titanium dioxide slurry, which is then wet-milled by a ball mill, and subjected to cyclone classification , the qualified slurry is transferred to the next process, and the unqualified slurry is transferred back to the beating tank for circular grinding, requiring control of 325 mesh sieve residue; the concentration of the crude titanium dioxide slurry is controlled at 800g / L, and the cyclone pressure is 0.3 MPa, 0.4% residue on 325 mesh sieve after swirl; dispersant is PAAS, and the addition amount is controlled between 0.8%;

[0069] Step S102, grind the slurry obtained in step S101 through a sand mill; and carry out s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com