High-performance environment-friendly coating and preparation method thereof

An environmentally friendly and high-performance technology, which is applied in the direction of cement coatings, antifouling/underwater coatings, radiation-absorbing coatings, etc., can solve the problems that the comprehensive performance of coatings needs to be improved, does not have other properties, and the effect is not ideal. Effects of reducing electromagnetic wave radiation, easy adhesion, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

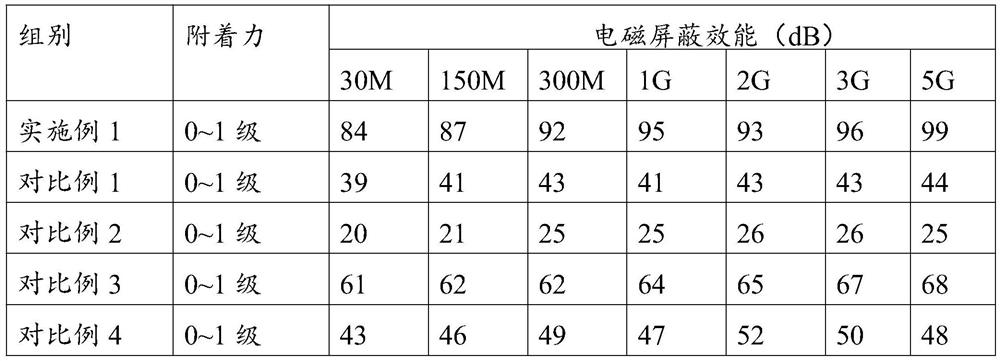

Examples

Embodiment 1

[0043] The present embodiment provides a kind of high-performance environmental protection coating, and it comprises composition as follows:

[0044] 0.04 mass parts of radiation-absorbing material, 70 mass parts of HPMC, 3 mass parts of ordinary aluminum silicate fibers, 1.5 mass parts of nano-silver powder, 1.5 mass parts of conductive micropowder (nanoscale SnO 2 Micropowder), 30 parts by mass of white cement, 22 parts by mass of Wacker rubber powder. The above-mentioned powders are vibrated by microwaves and mixed to form a radiation-proof coating that can be conveniently applied. Before use, add water, disperse evenly in a high-speed disperser / ball mill, and discharge to obtain slurry, which can be used for construction. If the slurry has been left to stand for a long time before use, ultrasonic vibration homogenization treatment is required before official use, and the following examples and comparative examples are the same.

Embodiment 2

[0046] The present embodiment provides a kind of high-performance environmental protection coating, and it comprises composition as follows:

[0047] 0.05 parts by mass of radiation absorbing material, 40 parts by mass of HBMC, 3 parts by mass of forsterite fiber, 0.5 parts by mass of nano-silver powder, 0.5 parts by mass of conductive micropowder (nanoscale SnO 2 Micropowder), 24 parts by mass of white cement, 20 parts by mass of Wacker rubber powder. The above-mentioned powders are vibrated by microwaves and mixed to form a radiation-proof coating that can be conveniently applied. Before use, add water, disperse evenly in a high-speed disperser / ball mill, and discharge to obtain slurry, which can be used for construction.

Embodiment 3

[0049] The present embodiment provides a kind of high-performance environmental protection coating, and it comprises composition as follows:

[0050] 0.06 parts by mass of radiation absorbing material, 5 parts by mass of expanded vermiculite, 5 parts by mass of expanded perlite, 50 parts by mass of HPMC, 3 parts by mass of polycrystalline alumina fiber, 0.5 parts by mass of nano-silver powder, 1 mass part Parts of conductive powder (nanoscale SnO 2 Micropowder), 35 parts by mass of white cement, 25 parts by mass of Wacker rubber powder. The above-mentioned powders are vibrated by microwaves and mixed to form a radiation-proof coating that can be conveniently applied. Before use, add water, disperse evenly in a high-speed disperser / ball mill, and discharge to obtain slurry, which can be used for construction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com