Lithium ion battery composite diaphragm, preparation method thereof and lithium ion battery

A technology of lithium-ion batteries and composite diaphragms, which is applied in secondary batteries, battery pack components, secondary battery repair/maintenance, etc., to achieve the effect of simple process, good heat resistance, strength and air permeability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

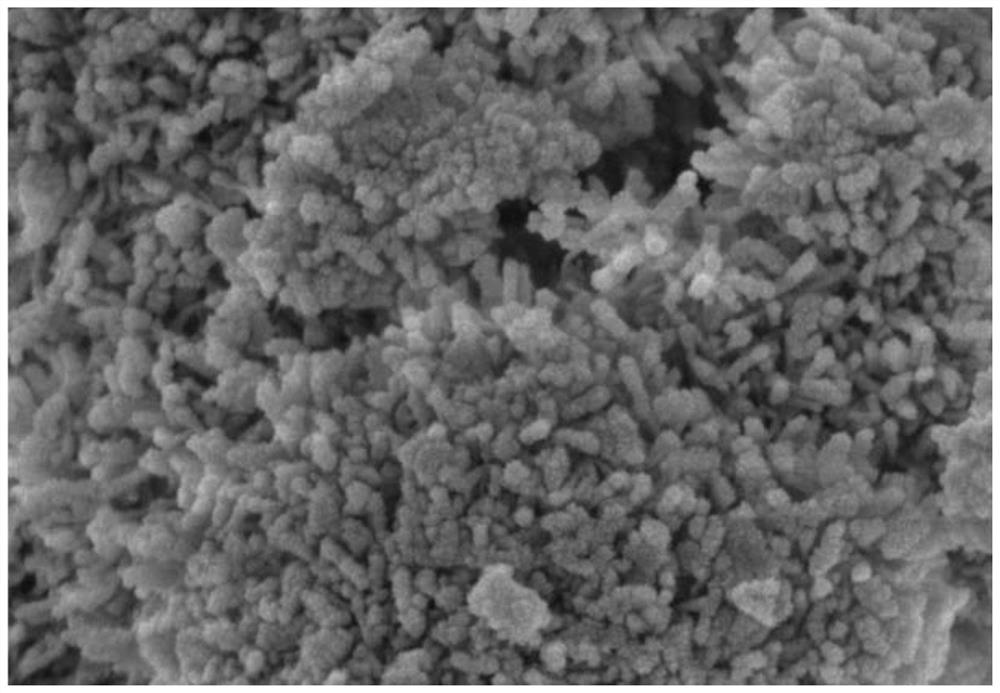

[0061] Add the first ceramic particles and the second ceramic particles with a weight ratio of 1:1 into deionized water at room temperature, and stir at a high speed of 1600 rpm for 15 minutes to obtain the first material; then add sodium polyacrylate, carboxymethyl fiber element, and stirred at a high speed of 1600 rpm for 1.5h to obtain the second material; reduce the rotational speed to 200 rpm, based on the total weight of the first ceramic particles and the second ceramic particles, and then add 13% by weight The polyacrylate emulsion continued to stir for 30min, the solid content of the polyacrylate emulsion was 40% by weight, and the coated slurry was prepared; the slurry was coated on both sides of a 16 μm polyolefin base film, and dried at 50°C. After baking and drying, a composite separator is obtained, and the thickness of the ceramic coating on each side is 2 μm.

[0062] Wherein, the first ceramic particle is Al with a particle size of 20nm sintered on the surface...

Embodiment 2

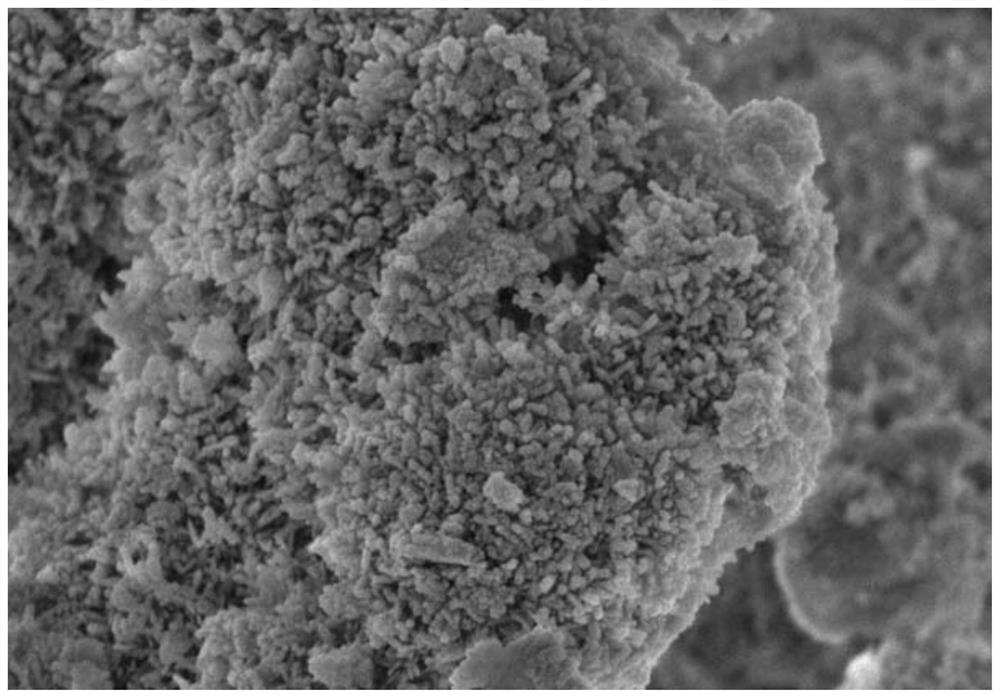

[0064]Add the first ceramic particles and the second ceramic particles with a weight ratio of 1:1 into deionized water at room temperature, and stir at a high speed of 1400 rpm for 20 minutes to obtain the first material; then add polyvinyl alcohol, methyl cellulose , and stirred at a high speed of 1400 rpm for 1.0h to obtain the second material; reduce the rotational speed to 300 rpm, based on the total weight of the first ceramic particles and the second ceramic particles, and then add 13% by weight of D The styrene-butadiene latex emulsion continued to stir for 30min, and the solid content of the styrene-butadiene latex emulsion was 25% by weight, and the coated slurry was prepared; the slurry was coated on both sides of a 16 μm polyolefin base film, baked at 50°C, After drying, a composite separator was obtained with a ceramic coating thickness of 4 μm on each side.

[0065] Among them, the first ceramic particle is SiO with a particle size of 40nm sintered on the surface....

Embodiment 3

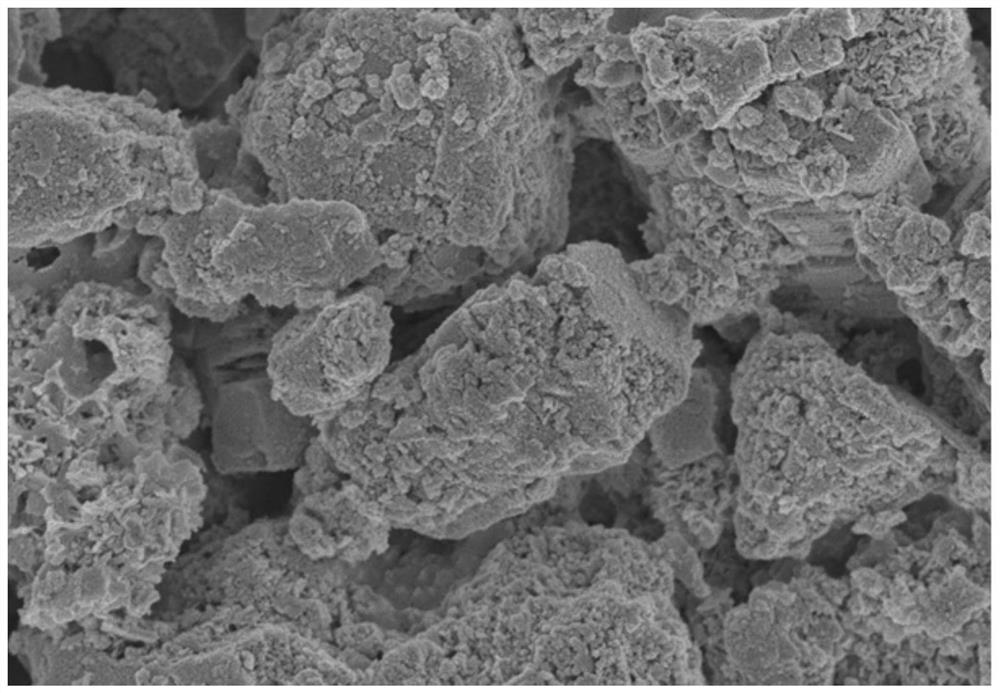

[0067] Add the first ceramic particles and the second ceramic particles with a weight ratio of 3:7 into deionized water at room temperature, and stir at a high speed of 1600 rpm for 20 minutes to obtain the first material; then add polyvinyl alcohol, methyl cellulose , and stirred at a high speed of 1600 r / min for 1.0 h to obtain the second material; reduce the rotating speed to 300 r / min, based on the total weight of the first ceramic particles and the second ceramic particles, and then add 12% by weight of poly The acrylate emulsion was stirred for 30 minutes, and the solid content of the polyacrylate emulsion was 40% by weight, and the coated slurry was prepared; the slurry was coated on both sides of a 16 μm polyolefin base film, baked at 50°C, After drying, a composite separator was obtained with a ceramic coating thickness of 4 μm on each side.

[0068] Among them, the first ceramic particle is SiO with a particle size of 40nm sintered on the surface. 2 Nanoparticles of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com