Fenton-containing sludge catalyst for water treatment, and preparation method and application method thereof

A catalyst and water treatment technology, applied in the field of water treatment, can solve the problems of wasting iron slime resources, increasing the operating cost of enterprises, catalyst broken, etc., and achieve the effects of increasing contact probability, ensuring service life and reducing calcination temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

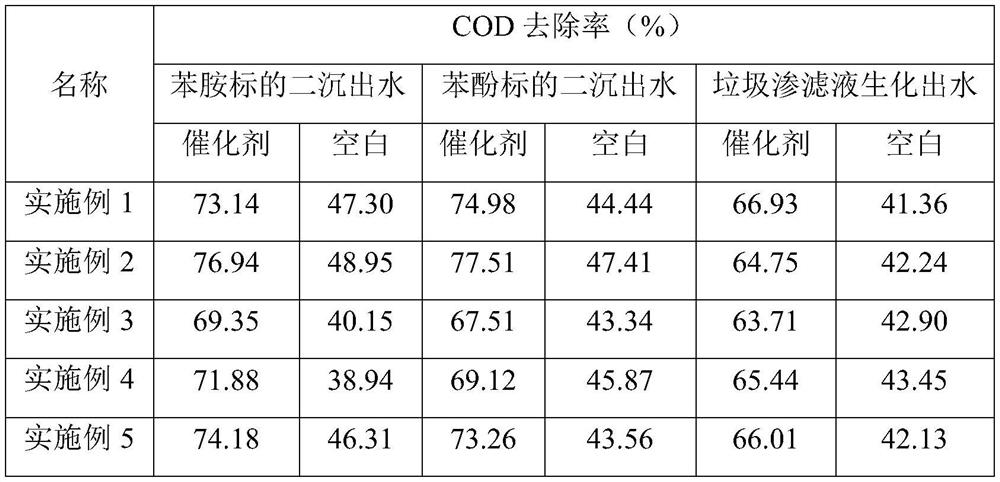

Examples

preparation example Construction

[0035] A method for preparing a water treatment catalyst containing Fenton's mud of the present invention comprises mixing clay, mica stone, sepiolite, kaolin and quartz stone with Fenton's mud to obtain a mixed material, and adding the mixed material to a granulator , roll molding to obtain catalyst prefabricated particles, and finally obtain a silicate-based Fenton's mud catalyst after drying and calcining. Its concrete preparation steps are as follows:

[0036] Step 1. Raw material mixing

[0037] The carrier material and Fenton's mud are placed in a ball mill tank, mixed and ball milled to obtain a uniformly dispersed mixed material. The ratio of the mass of Fenton's sludge added to the raw material to the total mass of clay, mica stone, sepiolite, kaolin and quartz stone is 0.1-0.3.

[0038] Step 2. Forming of catalyst prefabricated particles

[0039] Put the mixed material into the granulator, spray it into the aqueous solution for granulation treatment, and obtain ca...

Embodiment 1

[0044] 1. Raw material mixing

[0045] Put 400g of clay, 150g of mica stone, 100g of sepiolite, 150g of kaolin, 200g of quartz stone and 100g of Fenton's mud in a ball mill jar, mix and ball mill to obtain a uniformly dispersed mixture.

[0046] 2. Catalyst molding

[0047] Put the mixed material into the granulator, spray the aqueous solution into the granulation process at the speed of 15r / min, and obtain the catalyst prefabricated particles with a diameter of 6 mm after the granulation is completed;

[0048] 3. Calcination treatment

[0049] The catalyst prefabricated particles were put into a box-type resistance furnace, and the temperature was raised to 550°C at a rate of 1°C / min for calcination for 6 hours for calcination. After the calcination was completed, a high-strength silicate-based Fenton's mud catalyst with a diameter of 6mm was obtained.

Embodiment 2

[0051] 1. Raw material mixing

[0052] Put 400g of clay, 150g of mica stone, 100g of sepiolite, 150g of kaolin, 200g of quartz stone and 200g of Fenton's mud into a ball mill jar, mix and ball mill to obtain a uniformly dispersed mixture.

[0053] 2. Catalyst molding

[0054] Put the mixed material into the granulator, spray the aqueous solution into the granulation process at the speed of 20r / min, and obtain the catalyst prefabricated particles with a diameter of 8 mm after the granulation is completed;

[0055] 3. Calcination treatment

[0056] The catalyst prefabricated particles were put into a box-type resistance furnace, and the temperature was raised to 650°C at a rate of 1.5°C / min for calcination for 4 hours for calcination treatment. After the calcination was completed, a high-strength silicate-based Fenton's mud catalyst with a diameter of 8mm was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com