Colored polylactic acid tow and preparation method thereof

A polylactic acid, tow technology, applied in the manufacture of rayon, conjugated synthetic polymer rayon, filament/thread forming, etc., can solve the problems of affecting product stability, insecurity, easy color fading, etc. The effect of excellent color retention, enhanced differentiation, excellent coloring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A preparation method of colored polylactic acid tow, comprising the following steps:

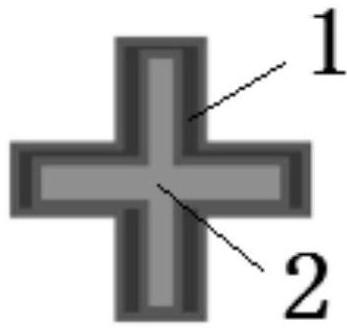

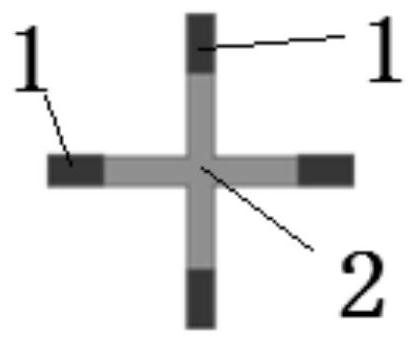

[0043] 1) Preparation of as-spun silk: Mix 60 parts of polylactic acid (40% crystallinity, 30 g / 10min melt index) and 0.1 part of nano-silica in the core layer, and place them in a vacuum drum dryer at 80°C for 12 hours, then cool Put the material below 45°C into the hopper of a single-screw extruder; place 39.9 parts of polylactic acid (crystallinity 5%, melt index 20g / 10min) in a vacuum drum dryer at 60°C for 24 hours, and cool to The material is fed into the hopper of another single-screw extruder below 45°C; the screw temperature is set at a gradient of 185-195-205-215-225°C, the filter temperature is 240°C, the spinneret is 240°C, and the spinneret hole is a cross-shaped nozzle Silk holes, cooling temperature 28°C, traction speed 850m / min, oiling, winding, and falling into barrels to collect primary tow.

[0044] 2) Preparation of post-spinning colored tows: according to the req...

Embodiment 2

[0051]A preparation method of colored polylactic acid tow, comprising the following steps:

[0052] 1) Preparation of as-spun silk: the core layer is composed of 80 parts of polylactic acid (crystallinity 25%, melt index 25g / 10min), 0.08 parts of nano-titanium dioxide are mixed and placed in a vacuum drum dryer at 80 ° C for 12 hours, cooled to 45 Blow the material into the hopper of the single-screw extruder below ℃; place 19.98 parts of polylactic acid (crystallinity 10%, melt index 30g / 10min) in the skin layer composition in a vacuum drum dryer at 60 ℃ for 24 hours, and cool to 45 ℃ The following materials are discharged into the hopper of another single-screw extruder; the screw temperature is set at a gradient of 185-195-205-215-225°C, the filter temperature is 244°C, the spinneret is 248°C, and the spinneret hole is a cross-shaped spinneret hole , the cooling temperature is 37°C, the traction speed is 1100m / min, oiling, winding, and falling into barrels to collect the pr...

Embodiment 3

[0060] A preparation method of colored polylactic acid tow, comprising the following steps:

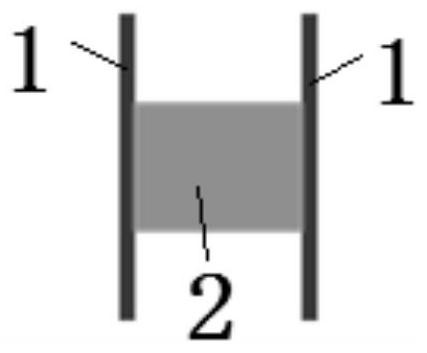

[0061] 1) Preparation of spun silk: the core layer is composed of 45 parts of polylactic acid (50% crystallinity, melt index 35g / 10min), 0.15 parts of carbon nanotubes are mixed and placed in a vacuum drum dryer at 80 ° C for 12 hours, cooled to Discharge the material below 45°C into the hopper of the single-screw extruder; place 54.85 parts of polylactic acid (crystallinity 15%, melt index 25g / 10min) in a vacuum drum dryer at 60°C for 24 hours and cool to 45°C. The material is discharged below ℃ into the hopper of another single-screw extruder; the screw temperature is set at a gradient of 185-195-205-215-225℃, the filter temperature is 237℃, the spinneret is 233℃, and the spinneret hole is H-shaped. Silk holes, cooling temperature 15°C, traction speed 650m / min, oiling, winding, and falling into barrels to collect primary tow.

[0062] 2) Preparation of post-spinning colored tows: a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com