Preparation method of wood fibers for papermaking

A technology of wood fiber and wood fiber powder, applied in papermaking, fiber raw materials, textiles and papermaking, etc., can solve the problems of paper performance and quality adverse effects, paper performance not improved or reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

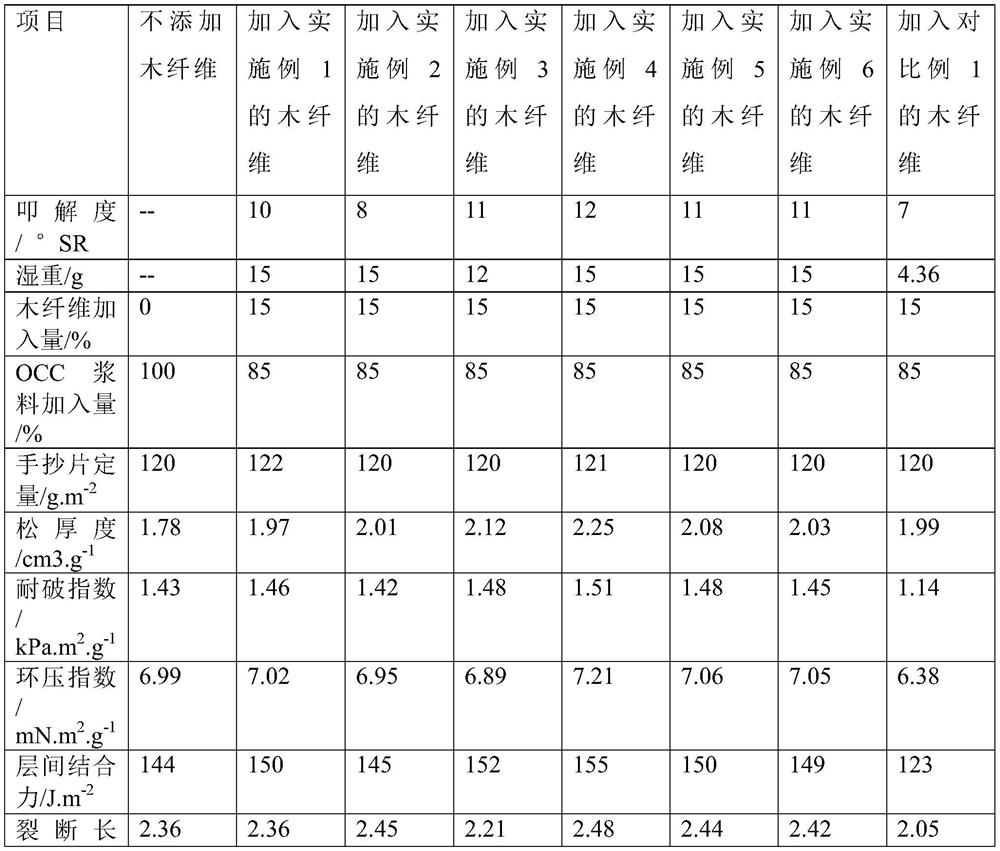

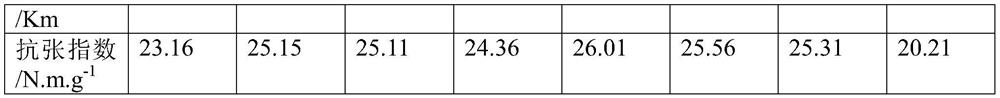

Examples

Embodiment 1

[0062] A method for preparing wood fibers for use in replacing waste paper or waste pulp in papermaking, comprising the steps of:

[0063] 1. Process the remaining corner waste from wood processing in general furniture factories, MDF factories and multi-layer board factories, as well as the remaining materials and sawdust in the wood harvesting process, into small wood or wood chips, with a size of 20-25mm in length and width 15-20mm, 2-5mm thick, control the moisture in small wood or wood chips to about 30%;

[0064] 2. Cook the treated fine wood or wood chips, the cooking temperature is 165°C, the cooking time is 5min, the cooking pressure is 1Mpa, the pH of the wood or wood chips is 4.5 during cooking, and then the cooked fine wood is sent into Go to the grinder for thermal grinding. After the thermal grinding is completed, dry it. The fineness of the wood fiber after thermal grinding is required to reach 20 mesh and the sieve rate is over 98%. The moisture content of the d...

Embodiment 2

[0068] A method for preparing wood fibers for use in replacing waste paper or waste pulp in papermaking, comprising the steps of:

[0069] 1. Process the remaining corner waste from wood processing in general furniture factories, MDF factories and multi-layer board factories, as well as the remaining materials and sawdust in the wood harvesting process, into small wood chips with a size of 20-25mm in length and 15 in width -20mm, 2-5mm thick, control the moisture in small wood or wood chips to about 30%;

[0070] 2. Cook the treated fine wood or wood chips, the cooking temperature is 160°C, the cooking time is 5min, the cooking pressure is 1Mpa, the pH of the wood or wood chips is 4.5 during cooking, and then the cooked fine wood is sent into Go to the grinder for thermal grinding, after the thermal grinding is completed, dry, the fineness of the wood fiber after thermal grinding is required to reach 20 mesh and the sieve rate is over 98%, and the moisture content of the dried...

Embodiment 3

[0074] A method for preparing wood fibers for use in replacing waste paper or waste pulp in papermaking, comprising the steps of:

[0075] 1. Process the leftover scraps from the processing of general wood factories, as well as the remaining materials and sawdust in the wood harvesting process, into small wood or wood chips, with a size of 20-25mm in length, 15-20mm in width, and 2-5mm in thickness. The moisture in fine wood or wood chips is controlled at about 35%;

[0076] 2. Cook the treated fine wood or wood chips, the cooking temperature is 180°C, the cooking time is 6min, the cooking pressure is 1.2Mpa, the pH of the wood or wood chips is 5 during cooking, and then the cooked fine wood is sent to Put it into the grinder for thermal grinding, after the thermal grinding is completed, it is dried, the fineness of the wood fiber powder after thermal grinding is required to reach 20 mesh and the sieve rate is more than 98%, and the moisture content of the dried wood fiber pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com