Preparation method and application of bismuth oxyiodate/bismuth oxybromide composite photocatalyst

A technology of bismuth oxyiodate and bismuth oxybromide, which is applied in catalyst activation/preparation, physical/chemical process catalyst, bismuth compound, etc., can solve the problems of limited visible light response capability and large forbidden band width, etc., and achieves a simple and feasible experimental method. , good matching and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

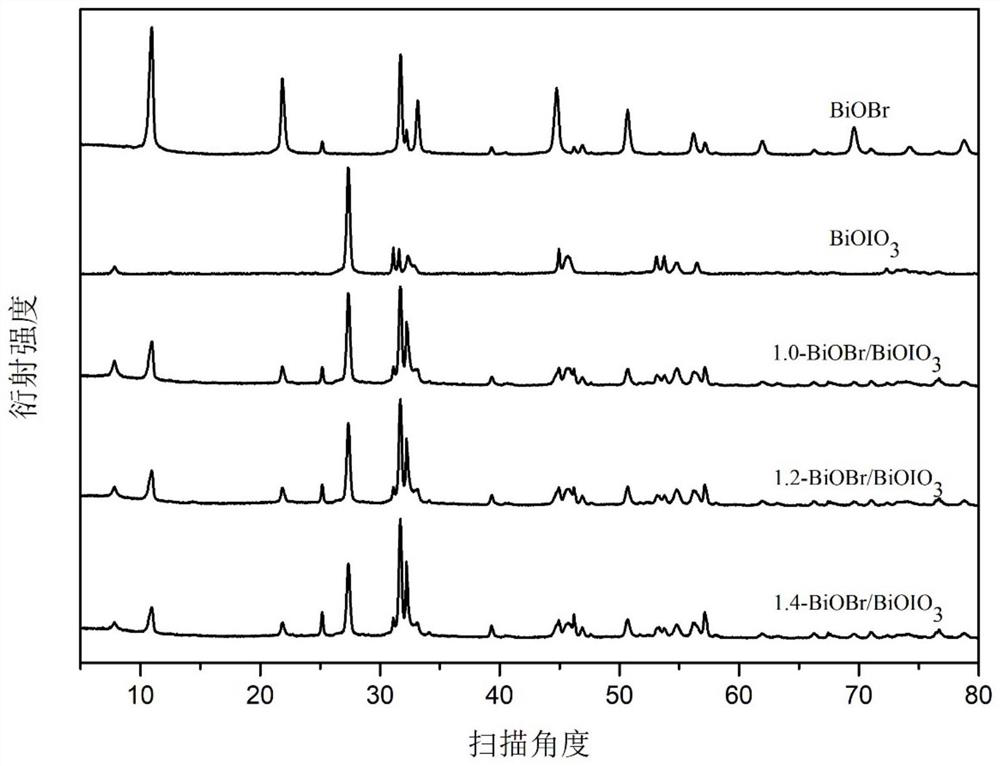

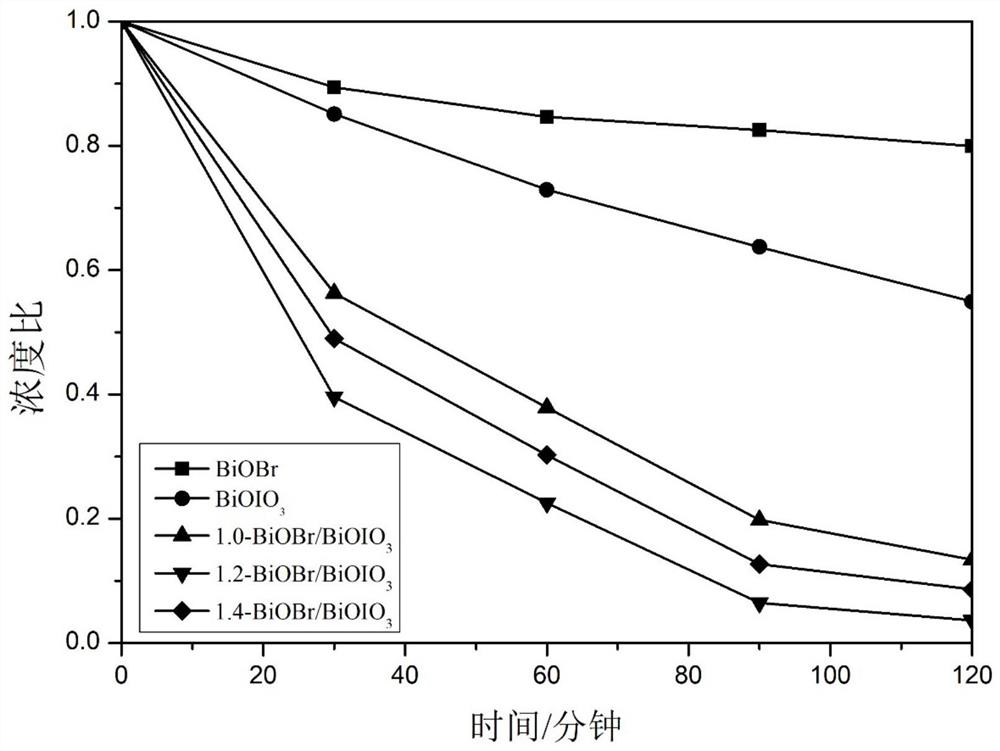

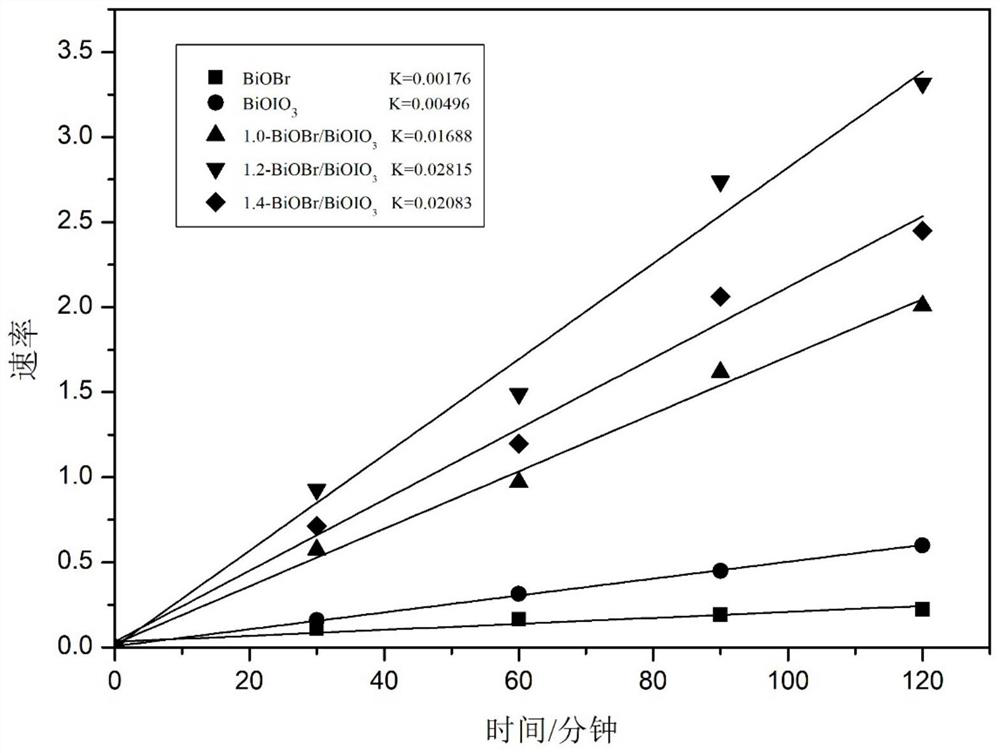

[0033] Step 1. Dissolve 0.485g of bismuth nitrate in 80ml of distilled water. After completely dissolving, add 0.214g of potassium iodate and stir for 10 minutes. Cool naturally, wash with distilled water and absolute ethanol alternately, and dry to obtain bismuth oxyiodate.

[0034] Step 2. Dissolve 1g of bismuth nitrate and 1g of hexadecyltrimethylammonium bromide in 50ml of distilled water, stir for 1h, transfer the resulting suspension to a 100ml reactor, react at 160°C for 18h, and cool naturally at room temperature , washed with distilled water and absolute ethanol alternately, and dried to obtain bismuth oxybromide.

[0035] Step 3. Add 0.1g of bismuth oxyiodate and 0.1g of bismuth oxybromide to 20ml of ethanol respectively, and sonicate for 1 hour. After the ultrasonication is completed, pour the bismuth oxyiodate solution into the bismuth oxybromide solution, and continue to sonicate the mixture for 2 hours. Add 20ml of acetone dropwise to the mixture with a rubber d...

Embodiment 2

[0037] Step 1. Dissolve 0.485g of bismuth nitrate in 80ml of distilled water. After completely dissolving, add 0.214g of potassium iodate and stir for 10 minutes. Cool naturally, wash with distilled water and absolute ethanol alternately, and dry to obtain bismuth oxyiodate.

[0038] Step 2. Dissolve 1g of bismuth nitrate and 1g of hexadecyltrimethylammonium bromide in 50ml of distilled water, stir for 2h, transfer the resulting suspension to a 100ml reactor, react at 140°C for 24h, and cool naturally at room temperature , washed with distilled water and absolute ethanol alternately, and dried to obtain bismuth oxybromide.

[0039] Step 3. Add 0.1g of bismuth oxyiodate and 0.12g of bismuth oxybromide to 20ml of ethanol respectively, and sonicate for 1 hour. After the ultrasonication is completed, pour the bismuth oxyiodate solution into the bismuth oxybromide solution, and continue to sonicate the mixture for 2 hours. Add 20ml of acetone dropwise into the mixture with a rubbe...

Embodiment 3

[0041] Step 1. Dissolve 0.485g of bismuth nitrate in 80ml of distilled water. After completely dissolving, add 0.214g of potassium iodate and stir for 10 minutes. Cool naturally, wash with distilled water and absolute ethanol alternately, and dry to obtain bismuth oxyiodate.

[0042] Step 2. Dissolve 1g of bismuth nitrate and 1g of hexadecyltrimethylammonium bromide in 50ml of distilled water, stir for 2h, transfer the resulting suspension to a 100ml reactor, react at 140°C for 24h, and cool naturally at room temperature , washed with distilled water and absolute ethanol alternately, and dried to obtain bismuth oxybromide.

[0043] Step 3. Add 0.1g of bismuth oxyiodate and 0.14g of bismuth oxybromide to 20ml of ethanol respectively, and sonicate for 1 hour. After the ultrasonication is completed, pour the bismuth oxyiodate solution into the bismuth oxybromide solution, and continue to sonicate the mixture for 2 hours. Add 20ml of acetone dropwise to the mixture with a rubber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com