A kind of method for preparing foamed graphene from antibiotic slag

A technology of antibiotic bacteria slag and foamed graphene, which is applied in the field of nanomaterials, can solve the problems of difficult control of doping amount, difficulty in commercial application, and difficulty in wide application, and achieve excellent electrochemical performance, excellent electrochemical performance, and easy The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

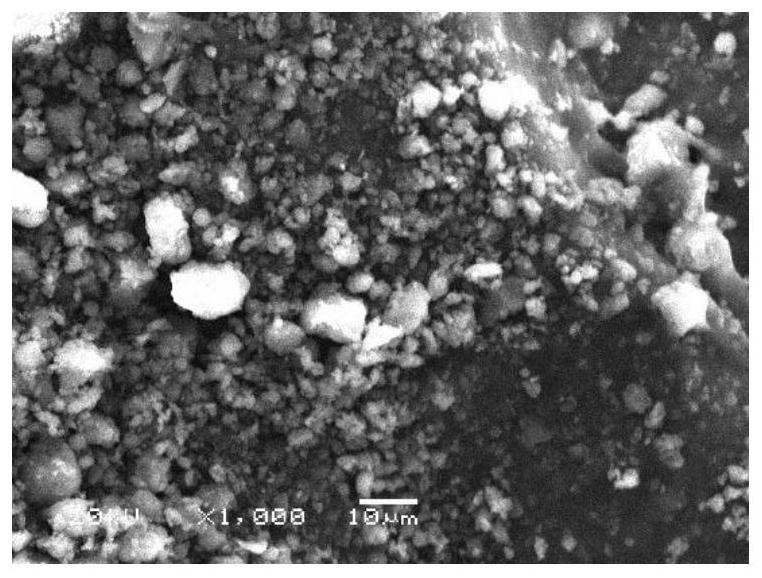

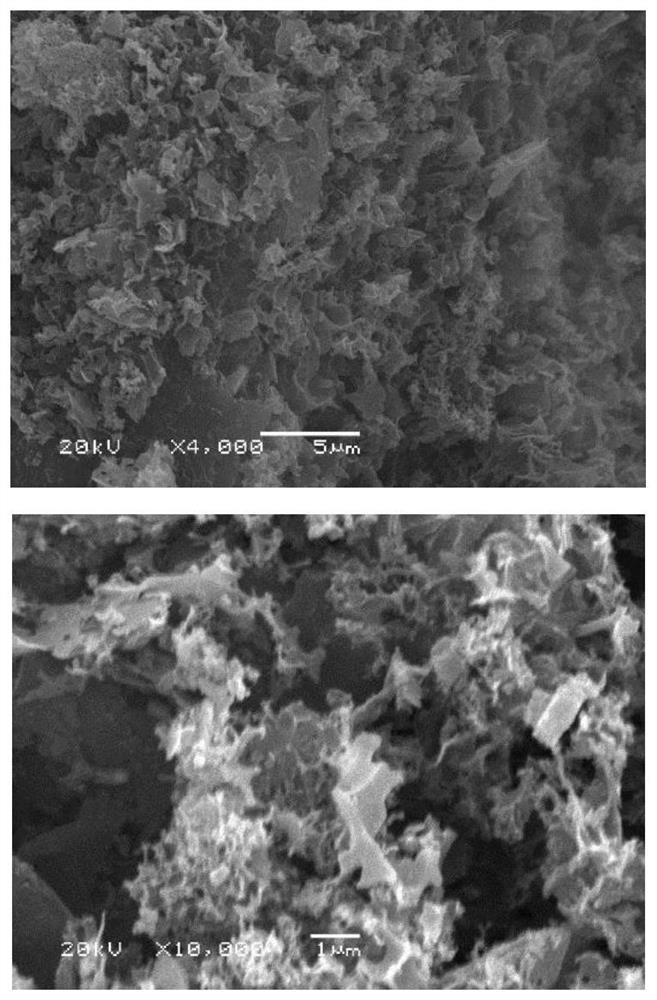

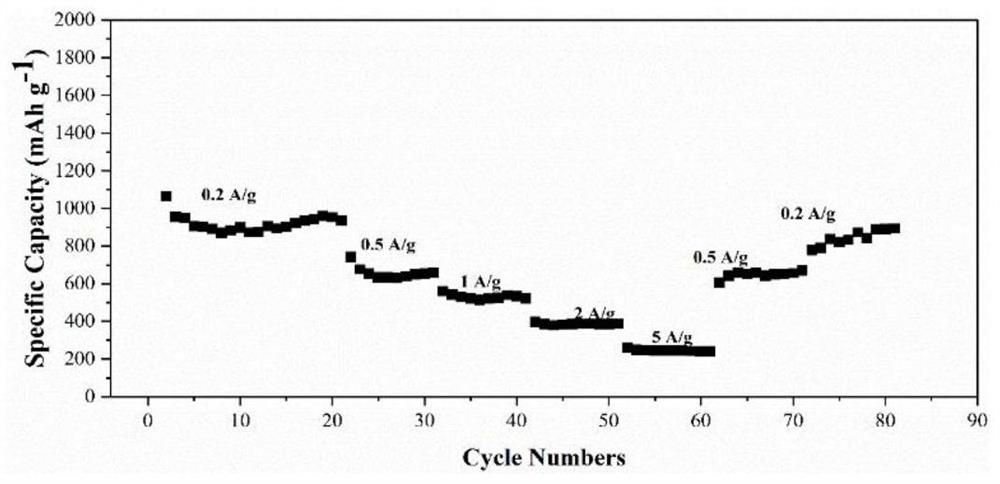

Image

Examples

Embodiment 1

[0061] ① Place the antibiotic bacteria residue in a vibrating mill and grind for 10 minutes to obtain the preliminary fine powdered antibiotic bacteria residue. Then put the previously obtained solid powder into an oven at 80-120°C for 24 hours, and dry it for later use;

[0062] ② Weigh 10g of dried antibiotic bacteria residue and 10g of potassium hydroxide, stir and disperse evenly with 60mL of ethanol, put it in a polytetrafluoroethylene tank, and then seal it in a stainless steel reactor, and then keep it in an oven at 200°C for about 12 hours ;

[0063] ③Separate the liquid-solid mixture obtained by ethanol heating in the previous step, add the liquid to hydrochloric acid for neutralization and dry to obtain the pretreated solid A; Same) to neutrality, oven dry, obtain pretreatment solid B;

[0064] ④ Step 4: Dissolve the solid powder obtained in the previous step (pretreatment solid B) in an appropriate amount of deionized water (the solid obtained by ethanol heat trea...

Embodiment 2

[0072] Compared with Example 1, the difference is only that the consumption of the alkali in step 4 all decreases, specifically:

[0073] ① Place the antibiotic bacteria residue in a vibrating mill and grind for 10 minutes to obtain the preliminary fine powdered antibiotic bacteria residue. Then put the previously obtained solid powder into an oven at 80-120°C for 24 hours, and dry it for later use;

[0074] ② Weigh 10g of dried antibiotic bacteria residue and 10g of potassium hydroxide, stir and disperse evenly with 60mL of ethanol, put it in a polytetrafluoroethylene tank, and then seal it in a stainless steel reactor, and then keep it in an oven at 200°C for about 12 hours ;

[0075] ③Separating the liquid-solid mixture obtained from the ethanol heating in the previous step, washing the separated solid (using ethanol washing), drying, and grinding into powder respectively for subsequent use;

[0076] ④ Step 4: Dissolve the solid powder obtained in the previous step in an ...

Embodiment 3

[0081] Compared with Example 1, the difference is mainly that the solvothermal solvent is methanol, specifically:

[0082] ① Place the antibiotic bacteria residue in a vibrating mill and grind for 10 minutes to obtain the preliminary fine powdered antibiotic bacteria residue. Then put the previously obtained solid powder into an oven at 80-120°C for 24 hours, and dry it for later use;

[0083] ② Weigh 10g of dried antibiotic bacteria residue and 10g of potassium hydroxide, stir and disperse evenly with 60mL of methanol, put it in a polytetrafluoroethylene tank, and then pack it in a stainless steel reactor, and then keep it in an oven at 200°C for about 12 hours ;

[0084] ③Separate the liquid-solid mixture obtained by heating methanol in the previous step, wash the solid with ethanol, dry it, and grind it into powder for subsequent use;

[0085] 4. Step 4: Dissolve the solid powder obtained in the previous step in an appropriate amount of deionized water (the solid produced...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com