A preparation method of laser retro-reflective unmanned vehicle coating

A retro-reflective and unmanned vehicle technology, applied in the direction of reflective/signal coatings, coatings, and devices for coating liquid on the surface, etc., can solve the problem of weak signal strength of the return receiver, affecting detection accuracy and distance, and high-energy laser damage and other problems, to achieve the effect of simple, convenient, fast and reliable operation, improved accuracy, and good total reflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

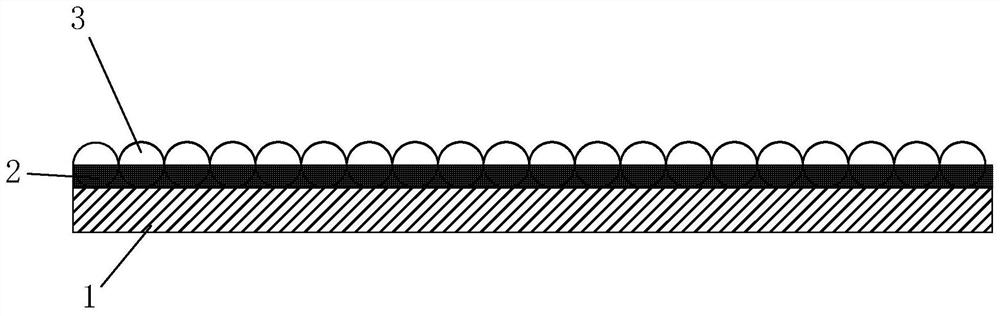

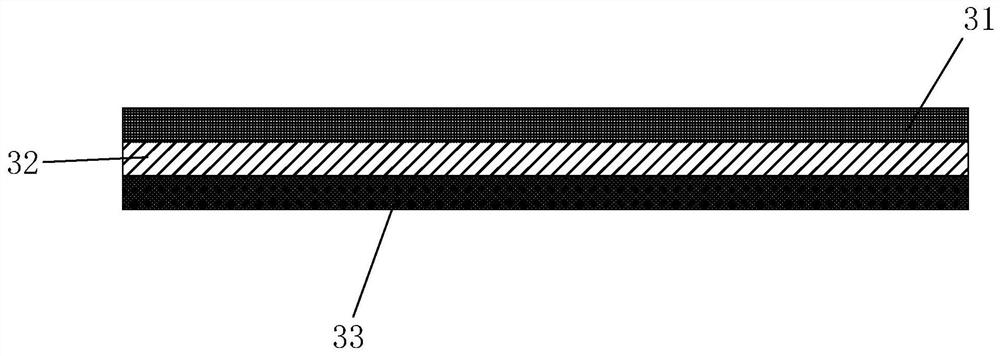

Image

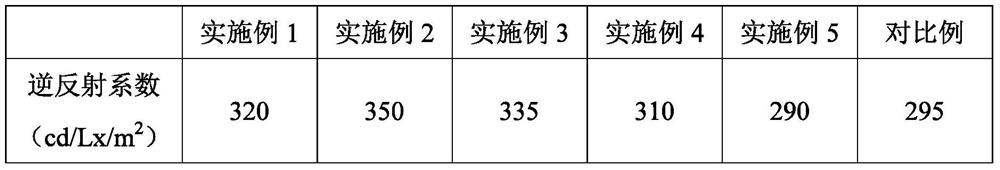

Examples

Embodiment 1

[0029] Metal-organic framework (MOF) material preparation: Weigh Cr(NO 3 ) 3 9H 2 O 0.50g and H 2 bdc-NH 2 0.23g\H 2 bdc 0.21g\H 2 bdc-Cl (Aladdin Reagent Co., Ltd.) 0.25g, add 7mL of water, stir to obtain a suspension, then add it into an autoclave lined with Teflon, place it at room temperature for 3h, and then heat it at 130°C under autogenous pressure 24h. After the reaction is over, take out the reaction kettle and allow it to cool naturally to room temperature, then open the reaction kettle, take out the product by centrifugation, repeatedly wash with absolute ethanol for more than 5 times to remove impurities, place the washed product in a nitrogen atmosphere and cool it at room temperature. Drying under conditions for 12h, and finally get the green pure product MIL-101(Cr)-NH 2 , MIL-101(Cr)-H and MIL-101(Cr)-Cl.

[0030] Preparation of coated glass microspheres: MIL-101(Cr)-Cl containing electron-withdrawing side groups was added to acetonitrile to make a sus...

Embodiment 2

[0034] Preparation of metal organic framework materials:

[0035] Metal-organic framework (MOF) material preparation: Weigh Cr(NO 3 ) 3 9H 2 O 0.50g and H 2 bdc0.21g\H 2 bdc-NH 2 0.23g\H 2 0.24g of bdc-CN was added to 7mL of water, stirred to obtain a suspension, then added to a Teflon-lined autoclave, left at room temperature for 3h, and then heated at 130°C for 24h under autogenous pressure. After the reaction is over, take out the reaction kettle and allow it to cool naturally to room temperature, then open the reaction kettle, take out the product by centrifugation, repeatedly wash with absolute ethanol for more than 5 times to remove impurities, place the washed product in a nitrogen atmosphere and cool it at room temperature. Drying for 12 hours under the condition, the green pure products MIL-101(Cr)-H, MIL-101(Cr)-NH are finally obtained 2 and MIL-101(Cr)-CN.

[0036]Preparation of coated glass microspheres 3: MIL-101(Cr)-CN containing electron-withdrawing sid...

Embodiment 3

[0040] Preparation of metal-organic framework materials:

[0041] Metal-organic framework (MOF) material preparation: Weigh Cr(NO 3 ) 3 9H 2 O 0.50g and H 2 bdc0.21g\H 2 bdc-CH 3 0.23g\H 2 0.24 g of bdc-CN was added to 7 mL of water, stirred to obtain a suspension, then added to a Teflon-lined autoclave, left at room temperature for 3 h, and then heated at 130 °C for 24 h under autogenous pressure. After the reaction is over, take out the reaction kettle and allow it to cool naturally to room temperature, then open the reaction kettle, take out the product by centrifugation, repeatedly wash with absolute ethanol for more than 5 times to remove impurities, place the washed product in a nitrogen atmosphere and cool it at room temperature. Drying for 12 hours under the condition, finally get green pure product MIL-101(Cr)-H, MIL-101(Cr)-CH 3 and MIL-101(Cr)-CN.

[0042] Preparation of coated glass microspheres 3: MIL-101(Cr)-CN containing electron-withdrawing side groups...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com